Industrial Automation Examples

CN

CN

About industrial automation examples

Where to Find Industrial Automation Examples Suppliers?

China leads global production of industrial automation systems, with key manufacturing clusters in Shandong, Guangdong, and Henan provinces. Shandong’s Qingdao region specializes in turnkey welding and robotic assembly lines, supported by integrated metal fabrication ecosystems that reduce component sourcing time by 25–30%. Guangdong’s Shenzhen-Dongguan corridor focuses on control systems and human-machine interfaces (HMIs), leveraging proximity to semiconductor and electronics supply chains for rapid prototyping and PCB integration.

These regions offer vertically integrated capabilities—from CNC machining and robotic integration to PLC programming and HMI design—enabling end-to-end automation solutions. Buyers benefit from consolidated supplier networks within 50km radii, reducing coordination overhead. Typical advantages include 20–35% cost savings compared to Western manufacturers, lead times of 30–60 days for custom systems, and scalability for both single-unit pilot deployments and full-line automation projects.

How to Choose Industrial Automation Examples Suppliers?

Evaluate suppliers using the following criteria to ensure technical reliability and transactional security:

Technical Capability Verification

Confirm expertise in core automation domains: programmable logic controllers (PLCs), industrial robotics, remote I/O modules, and HMIs. For system integration projects, verify experience with communication protocols such as EtherCAT, Profinet, and Modbus. Request documentation of prior installations, including system schematics and control logic diagrams.

Production Infrastructure Assessment

Assess operational scale and engineering capacity through the following indicators:

- Minimum factory area of 2,000m² for system integration and testing

- In-house engineering teams capable of PLC programming and robot path simulation

- On-site testing facilities for functional validation of automated lines

Cross-reference delivery performance (target ≥87%) and response times (ideally ≤5 hours) to gauge operational responsiveness.

Quality and Transaction Assurance

Prioritize suppliers with documented quality management practices. While formal ISO 9001 certification is not universally listed, consistent on-time delivery (100% among top performers) indicates process discipline. Utilize secure payment mechanisms and request pre-shipment inspection rights. Prototype testing is critical—validate robotic repeatability, sensor integration, and software interface usability before scaling procurement.

What Are the Best Industrial Automation Examples Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Stuaa Automation (Qingdao) Co., Ltd. | Shandong, CN | Welding Lines, Robotic Stations, Centrifugal Fans | $6,500–$300,000 | 1 set | 100% | ≤5h | - | - |

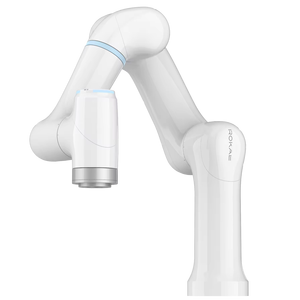

| Aieqip Corp. | Guangdong, CN | Collaborative Robots, Palletizers, Stacking Machines | $3,492–$11,800 | 1–10 sets | 100% | ≤3h | 100% | US $3,000+ |

| Dongguan Ailisen Trading Co., Ltd. | Guangdong, CN | Remote I/O Modules, PLCs, HMIs | $36.98–$158 | 1 piece | 87% | ≤4h | <15% | US $10,000+ |

| Shenzhen Muma Automation Technology Co., Ltd. | Guangdong, CN | PLCs, HMIs, 6-Axis Robots | $35–$15,000 | 1–5 pieces | 100% | ≤2h | 41% | US $300,000+ |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Automotive Assembly Lines, Battery Production Systems | $35,780–$88,600 | 1 set | 100% | ≤8h | - | - |

Performance Analysis

Stuaa Automation and Zhengzhou Duoyuan specialize in high-value turnkey systems, with prices exceeding $300,000 for fully automated welding lines, indicating advanced integration capabilities. Aieqip Corp. stands out in collaborative robotics with a 100% reorder rate, suggesting strong customer satisfaction in mid-range automation cells. Shenzhen Muma combines broad product range with high responsiveness (≤2h) and substantial online revenue, reflecting scalable operations. Dongguan Ailisen offers low-cost control components but has limited reorder activity, which may indicate lower engagement in long-term contracts. Buyers seeking full production lines should prioritize suppliers with proven system integration experience, while those sourcing individual automation components can leverage competitive pricing from modular equipment specialists.

FAQs

How to verify industrial automation supplier credibility?

Review technical documentation, including PLC code samples, HMI interface mockups, and robot motion simulations. Confirm compliance with electrical safety standards (e.g., CE marking for EU exports). Analyze historical order data, focusing on on-time delivery consistency and post-installation support responsiveness.

What is the typical lead time for industrial automation systems?

Standard robotic workstations require 30–45 days. Complex assembly lines or battery production systems may take 60–90 days due to customization and testing requirements. Component-level orders (e.g., I/O modules, HMIs) typically ship within 15 days.

Can suppliers provide customized automation solutions?

Yes, most suppliers support customization in programming, payload configuration, and integration with existing machinery. Shenzhen Muma and Aieqip explicitly list options for color, material, size, logo, and packaging. Submit detailed technical specifications—including cycle time, accuracy requirements, and communication protocols—for accurate quoting.

Do suppliers offer samples for testing?

Component suppliers (e.g., I/O modules, HMIs) often provide samples at reduced cost. For full robotic cells or production lines, suppliers may offer virtual simulations or on-site demos instead. Sample fees are typically applied toward bulk orders.

What are common minimum order quantities (MOQs)?

MOQs vary by product type: 1 set for complete automation lines, 1 piece for control components, and 10 sets for collaborative robots. Some suppliers waive MOQs for sample validation or pilot projects.