Iot Project Home Automation

1/3

1/3

1/3

1/3

1/20

1/20

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/3

1/3

0

0

0

0

1/3

1/3

1/35

1/35

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

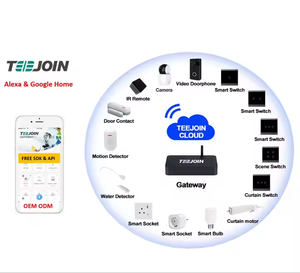

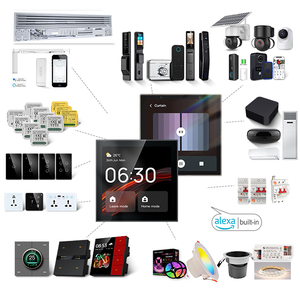

About iot project home automation

Where to Find IoT Project Home Automation Suppliers?

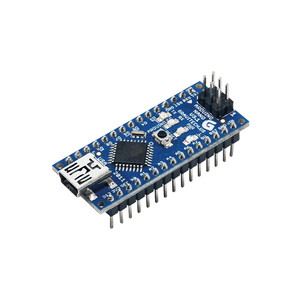

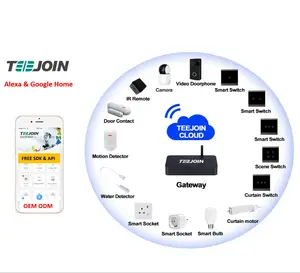

China leads global production of IoT-enabled home automation systems, with manufacturing hubs concentrated in Guangdong and Zhejiang provinces. Shenzhen, within Guangdong, serves as the epicenter of smart device innovation, hosting over 70% of China’s electronics OEMs and offering seamless access to microcontroller units (MCUs), wireless modules (Wi-Fi, Zigbee, Bluetooth 5.0+), and PCB assembly lines. The region's vertically integrated supply chain enables rapid prototyping and scalable production, reducing component procurement cycles by up to 40% compared to non-specialized regions.

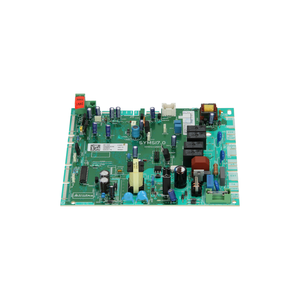

Zhejiang’s Hangzhou and Ningbo zones focus on mid-to-high volume consumer IoT deployments, leveraging automated SMT lines and firmware testing infrastructure. These clusters support end-to-end manufacturing—from sensor integration to cloud-connected gateway development—within tightly coordinated ecosystems. Proximity to Shenzhen’s semiconductor distributors and Hong Kong’s air freight terminals ensures lead times averaging 25–35 days for batch orders. Buyers benefit from localized sourcing of ABS/PC housing materials, RoHS-compliant soldering processes, and modular design frameworks that facilitate customization without compromising certification compliance.

How to Choose IoT Project Home Automation Suppliers?

Adhere to the following verification criteria when evaluating potential partners:

Technical Compliance

Confirm adherence to ISO 9001:2015 for quality management and IEC 62304 for medical-grade software safety where applicable. For EU and UK markets, CE and UKCA marking are mandatory; FCC Part 15 certification is required for U.S. entry. Verify EMC, ESD, and RF interference test reports—especially for Wi-Fi/BLE-based controllers. Ensure RoHS and REACH compliance documentation is available for material traceability.

Production Capability Audits

Assess operational scale and technical depth through the following benchmarks:

- Minimum 3,000m² production area with dedicated clean rooms for PCB assembly

- In-house capabilities including SMT placement, reflow soldering, AOI inspection, and functional testing

- Firmware development team comprising at least 8–10 engineers with experience in MQTT, REST APIs, and OTA update protocols

Validate monthly output capacity (typically 10,000–50,000 units) against historical order fulfillment data and on-time delivery performance (target ≥97%).

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow services until product validation is completed. Request sample units to verify hardware integrity, boot sequence reliability, and network handshake stability under real-world conditions. Prioritize suppliers with documented export experience to North America and Western Europe, confirmed via shipping records or customs documentation. Evaluate after-sales support responsiveness and SDK/documentation availability for integration assistance.

What Are the Best IoT Project Home Automation Suppliers?

No supplier data is currently available for analysis. Buyers should proactively screen manufacturers using verified business registries, conduct virtual factory audits, and request references from past clients in similar project scopes. Emphasis should be placed on firms demonstrating consistent certification maintenance, transparent production workflows, and proven track records in delivering interoperable IoT solutions compliant with Matter, HomeKit, or Google Home ecosystems.

Performance Analysis

In absence of specific supplier profiles, procurement strategy should focus on risk mitigation through phased engagement: initiate with small-batch trials, validate firmware-hardware synchronization, and assess long-term device uptime before scaling. Preference should be given to suppliers operating ISO-certified facilities with demonstrated experience in IoT security protocols (e.g., TLS 1.2+, secure boot, encrypted storage). Video audits of production lines and live demonstrations of QA procedures can serve as critical differentiators when comparing otherwise unranked vendors.

FAQs

How to verify IoT home automation supplier reliability?

Cross-verify business licenses with local industry bureaus. Obtain third-party audit reports covering production controls, environmental compliance, and software version management. Scrutinize customer testimonials focusing on post-deployment support, firmware update frequency, and defect resolution timelines.

What is the average sampling timeline?

Standard samples take 10–18 days to produce, depending on component availability. Systems requiring custom PCBs or proprietary sensor integration may require 25–35 days. Air freight adds 5–9 days for international delivery.

Can suppliers ship IoT home automation products worldwide?

Yes, experienced exporters manage global logistics via FOB, CIF, or DDP terms. Confirm compliance with destination-specific telecom regulations (e.g., FCC ID, ICES-003, RCM) and data privacy standards (GDPR, CCPA) for cloud-dependent devices. Sea freight is optimal for containerized shipments exceeding 500 units.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to minimum order quantities (typically ≥500 units). Otherwise, expect to cover 50–70% of unit cost, refundable upon order confirmation.

How to initiate customization requests?

Submit detailed specifications including microcontroller type (ESP32, STM32, etc.), communication protocol requirements, power supply (battery/mains), enclosure IP rating, and cloud platform compatibility. Reputable suppliers respond with circuit diagrams, bill of materials (BOM), and 3D CAD models within 5–7 business days.