Iot Projects Home Automation

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/1

1/1

0

0

1/10

1/10

1/3

1/3

1/3

1/3

1/1

1/1

1/35

1/35

0

0

1/3

1/3

1/3

1/3

About iot projects home automation

Where to Find IoT Projects Home Automation Suppliers?

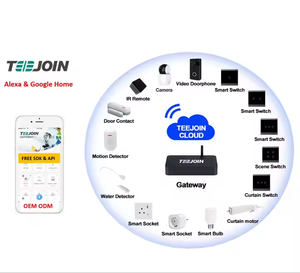

China remains the central hub for electronics manufacturing, with concentrated supplier ecosystems in Guangdong, Zhejiang, and Jiangsu provinces driving innovation and scale in smart home automation solutions. Shenzhen, located in Guangdong, hosts over 70% of China’s IoT hardware developers, supported by a fully integrated supply chain spanning PCB fabrication, sensor module production, and wireless communication technologies. The region's proximity to Hong Kong enables rapid prototyping and efficient export logistics, reducing time-to-market by 25–40% compared to non-specialized regions.

These industrial clusters benefit from vertical integration across microelectronics assembly, firmware development, and cloud connectivity infrastructure. Suppliers within these zones typically operate within tightly networked ecosystems—component vendors, contract manufacturers (CMs), and software engineers are often co-located within 30km radii—enabling agile development cycles and fast iteration for custom IoT projects. Key advantages include lead times averaging 20–35 days for small-batch production, 15–25% lower unit costs due to localized component access, and strong technical flexibility for Wi-Fi, Zigbee, Z-Wave, or Matter protocol integration.

How to Choose IoT Projects Home Automation Suppliers?

Adopt structured evaluation criteria to ensure technical reliability and supply chain stability:

Quality & Compliance Verification

Confirm adherence to international standards including ISO 9001 for quality management and IEC 62304 for medical-grade software safety where applicable. For EU and North American markets, CE, FCC, and RoHS certifications are mandatory for electromagnetic compatibility and hazardous substance control. Request test reports for signal stability, power consumption under load, and OTA (over-the-air) update resilience.

Technical Capability Assessment

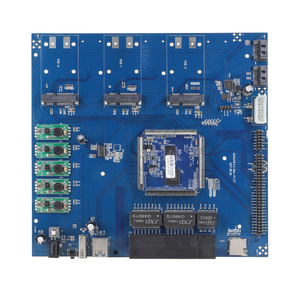

Evaluate core competencies through documented evidence:

- Minimum 3-year experience in end-to-end IoT product development

- In-house capabilities covering circuit design, embedded firmware (C/C++/Python), and mobile/cloud API integration

- Support for dual-band Wi-Fi (2.4GHz/5GHz), Bluetooth 5.0+, or multi-protocol gateways

Validate performance benchmarks using reference designs or existing customer deployments.

Production & Transaction Safeguards

Require proof of ESD-safe production lines and automated optical inspection (AOI) systems for PCB quality assurance. Prioritize suppliers offering third-party payment protection and post-delivery technical support. Conduct pre-shipment validation via functional testing of sample units under real-world network conditions. Use incremental order scaling—start with pilot batches of 100–500 units—to assess consistency before volume ramp-up.

What Are the Best IoT Projects Home Automation Suppliers?

No verified suppliers were identified in the current dataset matching the specified product category. This may reflect limited public disclosure of operational metrics, absence of standardized certification reporting, or insufficient transaction history on traceable channels. Buyers should proactively engage potential partners through industry trade shows (e.g., Canton Fair, Electronica) or B2B platforms that provide audit-backed profiles to identify qualified candidates.

Performance Analysis

In the absence of quantifiable supplier data, sourcing focus should shift to capability screening. Emphasis must be placed on verifying actual R&D capacity—not just trading intermediaries—by requesting project portfolios, firmware architecture diagrams, and evidence of prior smart home integrations with platforms like Google Home, Amazon Alexa, or Apple HomeKit. Geographic proximity to Shenzhen’s Huaqiangbei electronics market increases likelihood of direct manufacturer access and faster troubleshooting response.

FAQs

How to verify IoT home automation supplier reliability?

Cross-validate ISO and product-specific certifications with issuing bodies. Request case studies detailing past deployments, including failure rates and field return statistics. Conduct video audits of production floors and firmware testing labs to confirm technical infrastructure.

What is the average sampling timeline?

Standard IoT device samples take 10–20 days to produce, depending on complexity. Units requiring cloud backend integration or voice assistant certification may require 25–35 days. Add 5–8 days for express international shipping (DHL/FedEx).

Can suppliers ship worldwide?

Yes, most established manufacturers support global distribution under FOB, CIF, or DDP terms. Confirm compliance with destination regulations—particularly FCC Part 15 in the U.S. and RED Directive in the EU—for radio-frequency emitting devices. Air freight is recommended for samples; sea freight optimizes cost for orders exceeding 500 kg.

Do manufacturers provide free samples?

Sample policies vary: some suppliers waive fees for confirmed bulk orders (typically MOQ ≥500 units). Otherwise, expect to pay full production cost plus shipping, which can range from $50–$200 per unit depending on functionality.

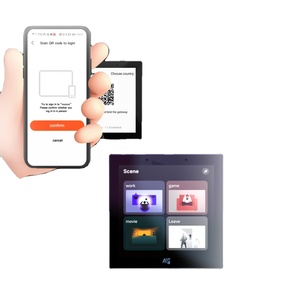

How to initiate customization requests?

Submit detailed specifications including microcontroller type (ESP32, STM32, etc.), required sensors (PIR, temperature, humidity), power source (mains/battery), enclosure IP rating, and preferred app interface (white-label or branded). Reputable suppliers respond with system block diagrams and bill-of-materials (BOM) within 5 business days.