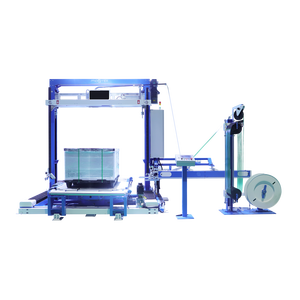

Itw Signode Box Strapping Machine

Top sponsor listing

Top sponsor listing

About itw signode box strapping machine

Where to Find ITW Signode Box Strapping Machine Suppliers?

China remains the global hub for industrial packaging machinery manufacturing, with key supplier clusters in Jiangsu, Shandong, and Henan provinces. These regions host vertically integrated production ecosystems specializing in strapping equipment compatible with ITW Signode standards. Nantong in Jiangsu Province is recognized for high-volume semi-automatic and automatic strapping machine output, supported by mature supply chains for motors, tensioners, and sealing heads. Shandong’s Weifang and Jinan zones focus on heavy-duty automated systems, leveraging proximity to steel and casting facilities to reduce component costs by 15–20% compared to Western alternatives.

The concentration of engineering talent and Tier-2 component suppliers within 50km radii enables rapid prototyping and scalable production. Facilities typically operate under ISO 9001 quality frameworks, with lead times averaging 20–35 days for standard configurations. Buyers benefit from modular designs that support compatibility with PP, PET, and composite straps used in ITW Signode applications, as well as cost advantages—up to 40% lower than OEM equivalents—due to optimized labor and logistics infrastructure.

How to Choose ITW Signode Box Strapping Machine Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compatibility & Compliance

Confirm machine specifications align with ITW Signode strap dimensions (typically 12–16mm width) and sealing mechanisms. Demand evidence of CE or CCC certification for electrical safety compliance. Review test reports for cycle durability (target ≥10,000 cycles), tensile force accuracy (±5%), and motor insulation class (IP54 minimum).

Production Capacity Verification

Assess core manufacturing capabilities through the following criteria:

- Minimum factory area of 2,000m² for stable batch production

- In-house machining for critical components (sealing jaws, drive wheels, tension arms)

- Dedicated assembly lines with functional testing stations

Cross-reference claimed output volumes with verified on-time delivery rates (prefer >97%) and online revenue indicators.

Customization & After-Sales Support

Evaluate flexibility for voltage (110V/220V/380V), strap feed direction, table height, and control panel language adjustments. Prioritize suppliers offering CAD drawings, pre-shipment inspection access, and spare parts kits. Transaction security improves when escrow or platform-backed payment terms are available, especially for first-time engagements.

What Are the Best ITW Signode Box Strapping Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Nantong Huabo Technology Co., Ltd. | Jiangsu, CN | Wrapping Machines (2,967) | 100% | ≤2h | <15% | US $20,000+ | Color, material, size, logo, packaging |

| Zhengzhou JYD Machine Co., Ltd. | Henan, CN | Automatic Strapping Machines (5+ models) | 100% | ≤4h | 25% | US $390,000+ | Color, material, size, logo, label, graphic |

| Anhui Ditu Import And Export Co., Ltd. | Anhui, CN | Wrapping Machines (172) | 98% | ≤1h | <15% | US $70,000+ | Color, material, size, logo, weight, packaging, plug, battery, graphic |

| Shanghai Lions Machinery Co., Ltd. | Shanghai, CN | Wrapping Machines (28) | 85% | ≤1h | 42% | US $10,000+ | Limited customization per listing |

| Shandong Rino International Trade Co., Ltd. | Shandong, CN | Paper Processing Machinery (64) | 100% | ≤3h | <15% | US $1,000+ | Primarily standard models |

Performance Analysis

Nantong Huabo and Zhengzhou JYD demonstrate strong operational reliability with 100% on-time delivery and extensive product listings, indicating established production lines. Zhengzhou JYD stands out with a high reorder rate (25%) and significant online revenue, suggesting consistent customer satisfaction. Anhui Ditu offers broad customization breadth—including voltage, plug type, and battery integration—ideal for region-specific deployments. While Shanghai Lions has fast response times, its lower delivery performance (85%) may pose fulfillment risks. Shandong Rino, though punctual, focuses primarily on paper processing machinery, positioning its strapping offerings as secondary lines with limited scalability.

FAQs

How to verify ITW Signode box strapping machine supplier reliability?

Cross-check certifications (CE, ISO 9001) with official registries. Request factory audit reports or video walkthroughs showing CNC machining centers, assembly benches, and final testing procedures. Analyze transaction history metrics such as on-time delivery rate, dispute resolution speed, and repeat order frequency.

What is the typical MOQ and lead time?

Most suppliers list MOQ at 1 set, enabling sample procurement. Lead times range from 15–25 days for standard units; customized configurations may require 30–40 days depending on mechanical modifications or control system adjustments.

Can suppliers provide machines compatible with ITW Signode straps?

Yes, many manufacturers design sealing mechanisms and strap pathways to accommodate 12–16mm wide PP/PET straps commonly used in Signode systems. Confirm compatibility in writing before ordering, particularly for joint sealing temperature and pressure settings.

Do suppliers offer free samples?

Free samples are rare for industrial-grade strapping machines. However, some vendors credit sample costs against future bulk orders (e.g., ≥5 units). Expect sample pricing between $1,200–$2,000 for semi-automatic models.

How to initiate customization requests?

Submit detailed requirements including power supply voltage, desired cycle speed (straps/min), table configuration, strap type, and environmental conditions (indoor/outdoor use). Reputable suppliers respond with technical drawings within 72 hours and can dispatch prototypes within 3–4 weeks.