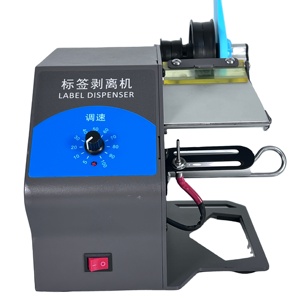

Label Remover Machine Producer

1/20

1/20

1/18

1/18

1/12

1/12

CN

CN

1/21

1/21

1/23

1/23

1/20

1/20

1/15

1/15

About label remover machine producer

Where to Find Label Remover Machine Producers?

China remains the central hub for label remover machine manufacturing, with key production clusters in Guangdong, Jiangsu, and Shandong provinces. These regions host vertically integrated facilities specializing in industrial automation and recycling equipment, enabling scalable output and cost-efficient component sourcing. Guangzhou and Shenzhen-based producers focus on compact, semi-automated units for small-to-mid-scale operations, while Jiangsu and Shandong manufacturers emphasize heavy-duty, fully automated systems integrated into plastic and glass recycling lines.

The industrial ecosystem supports rapid prototyping and customization, with localized access to CNC machining, sheet metal fabrication, and motor assembly. This integration reduces lead times by 20–30% compared to offshore alternatives. Suppliers typically maintain in-house R&D teams to adapt machinery for specific substrate types—PET, HDPE, PP, PE, and glass—ensuring compatibility across packaging formats. Buyers benefit from modular designs that allow integration into existing washing or sorting lines, particularly in bottle recycling facilities.

How to Choose Label Remover Machine Producers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

Assess machine specifications against application needs: width capacity (5–180mm), voltage (110V–220V), and material compatibility. Automated models with adjustable diameter rollers and speed controls offer higher throughput for industrial users. Verify whether the producer offers customization for label size, removal method (peeling, heating, or friction-based), and integration with conveyor systems.

Production and Quality Assurance

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not universally listed, consistent on-time delivery rates above 97% indicate reliable internal processes. Evaluate response time as a proxy for customer service efficiency—suppliers responding within 3 hours are more likely to support urgent inquiries and post-sale troubleshooting.

- Minimum facility area of 2,000m² suggests capacity for batch production

- In-house engineering teams enable faster customization cycles

- Proven export experience, evidenced by multilingual documentation and international compliance standards (CE, RoHS), enhances cross-border reliability

Transaction and Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with delivery and performance verification. Request product videos or factory audits to validate claims about automation level and build quality. For high-volume procurement, insist on sample testing under real-world conditions—particularly for adhesive residue removal efficiency and material throughput rates.

What Are the Leading Label Remover Machine Producers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Hongma Electronic Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $720,000+ | 98% | ≤3h | 19% | Manual/Semi-Auto Label Removers | $50.39–$125.99 |

| Laizhou Ledar Machinery Co., Ltd. | Shandong, CN | Manufacturer | US $50,000+ | 100% | ≤1h | - | Recycling Line Integrated Systems | $1,428.57–$13,571.42 |

| Jiangsu Kitech Machinery Co., Ltd. | Jiangsu, CN | Manufacturer | US $240,000+ | 100% | ≤5h | 100% | Plastic Recycling & Washing Lines | $45,000–$50,000 |

| NST TECHNOLOGY LLC | Shandong, CN | Manufacturer | - | - | ≤3h | - | Wine Bottle & Glass Processing | $5,199–$5,999 |

| Shenzhen Weiye Mechanical Equipment Co., Ltd. | Guangdong, CN | Manufacturer | US $220,000+ | 97% | ≤2h | <15% | Industrial Peelers & Dispensers | $65–$1,650 |

Performance Analysis

Guangzhou Hongma and Shenzhen Weiye specialize in entry-level to mid-range label removers priced under $1,700, ideal for startups or niche applications like wine bottle reconditioning. Their fast response times (≤3h) and low MOQs (1 unit) facilitate agile procurement. In contrast, Jiangsu Kitech and Laizhou Ledar target large-scale recyclers with full-line solutions, reflected in six-figure price points and integration capabilities. NST TECHNOLOGY focuses on glass-specific processing, offering rotary separation units at competitive pricing.

Notably, Jiangsu Kitech stands out with a 100% reorder rate, suggesting strong customer satisfaction despite longer response times. Laizhou Ledar achieves perfect on-time delivery, indicating disciplined production planning. Buyers seeking turnkey recycling systems should prioritize suppliers with demonstrated experience in PET/PP/HDPE processing and wastewater handling integration.

FAQs

What is the typical minimum order quantity (MOQ) for label remover machines?

Most suppliers list an MOQ of 1 unit for standard models, allowing buyers to test performance before scaling. Larger industrial systems may require orders of 1 set or more, especially for customized configurations.

How long does it take to receive a sample or initial order?

Sample lead times range from 7 to 15 days for off-the-shelf units. Customized or automated systems may require 25–40 days for production, plus 7–14 days for international shipping via air or sea freight.

Can label remover machines handle different bottle materials?

Yes, reputable producers design machines for multi-material use, including PET, HDPE, PP, PE, and glass. Confirm compatibility with specific label adhesives and substrates during technical consultation, especially for hot-melt or UV-resistant labels.

Do suppliers offer customization options?

Many producers support customization in color, voltage, plug type, labeling size, and automation level. Guangzhou Hongma and Shenzhen Weiye explicitly list adjustable diameter and graphic interface modifications. Full engineering changes require NRE fees and prototype validation.

Are there certifications I should verify when sourcing label remover machines?

While not all suppliers list formal certifications, prioritize those providing CE marking, electrical safety compliance, or RoHS declarations. For integration into regulated recycling plants, ensure machines meet local occupational safety and environmental discharge standards.