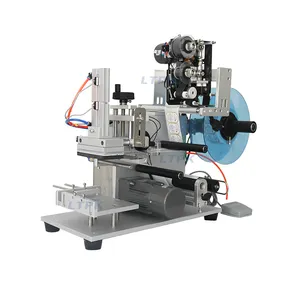

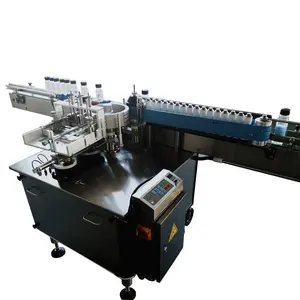

Labelling Machine For Jars

1/5

1/5

1/12

1/12

1/12

1/12

1/25

1/25

1/23

1/23

1/24

1/24

1/22

1/22

About labelling machine for jars

Where to Find Labelling Machine for Jars Suppliers?

China remains the global hub for labelling machine manufacturing, with key production clusters in Guangdong and Fujian provinces driving innovation and cost efficiency. Shenzhen and Dongguan in Guangdong host advanced automation facilities specializing in semi-automatic and fully automatic labelling systems, leveraging proximity to electronics and precision engineering supply chains. Xiamen in Fujian has emerged as a center for compact, tabletop labelling equipment, catering to small-to-mid-scale food, cosmetic, and pharmaceutical producers requiring flexible packaging solutions.

These industrial zones benefit from vertically integrated component sourcing—servo motors, sensors, and control panels are available within regional supplier networks, reducing lead times by 20–30% compared to offshore alternatives. The concentration of technical talent and rapid prototyping capabilities enables suppliers to support both high-volume orders and customized configurations. Buyers typically experience lead times of 15–30 days for standard models, with localized logistics infrastructure facilitating efficient export processing.

How to Choose Labelling Machine for Jars Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Assessment

Confirm compatibility with jar geometries (round, square, or irregular) and label types (pressure-sensitive, wrap-around, or top-labeling). Machines should support adjustable labeling speeds (30–150 bottles per minute) and accommodate container diameters ranging from 30mm to 150mm. For automated lines, verify integration readiness with existing conveyors and PLC-based control systems.

Production and Quality Verification

Prioritize suppliers demonstrating measurable quality control metrics:

- On-time delivery rate exceeding 95%

- Response time under 4 hours for inquiry resolution

- Documented customization options (material, color, size, labeling precision)

- Evidence of internal testing protocols for adhesive consistency and label placement accuracy (±1mm tolerance)

Certifications such as ISO 9001 or CE are strong indicators of standardized manufacturing processes, though not universally present among niche suppliers.

Procurement Safeguards

Utilize secure payment mechanisms that align financial release with delivery milestones. Request sample units to validate performance under real-world conditions, particularly for specialized applications like curved surface labeling or moisture-resistant adhesives. Evaluate after-sales support responsiveness, especially for software-driven models requiring firmware updates or sensor recalibration.

What Are the Best Labelling Machine for Jars Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Juste Machine Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $230,000+ | 100% | ≤3h | <15% | Color, material, size, logo, packaging, label, weighing, graphic | Fully automatic, high-speed, dual-side applicators |

| Dongguan Sammi Packing Machine Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $380,000+ | 88% | ≤2h | <15% | Color, diameter, material, size, label width/length, label size | Semi-automatic, desktop, manual jam jar models |

| Xiamen Greatbond Technology Co., Ltd. | Fujian, CN | Multispecialty Supplier | US $210,000+ | 100% | ≤3h | <15% | Color, material, size, logo, packaging, label, graphic | MT-series manual/semi-auto, MT-100/200 automatic vertical |

| Henan Tianzhong Machinery Co., Ltd. | Henan, CN | Not Specified | US $140,000+ | 100% | ≤2h | <15% | Limited public detail; broad machinery portfolio suggests adaptability | Semi-automatic round jar, PVC sticker, flat label applicators |

| Shenzhen Yichengxing Electronic Co., Ltd. | Guangdong, CN | Not Specified | US $7,000+ | 100% | ≤4h | <15% | Basic mechanical adjustments; orientation-specific models | Manual labeling, MP-36 series, low-cost entry-level units |

Performance Analysis

Shenzhen Juste and Xiamen Greatbond demonstrate consistent on-time delivery (100%) and robust customization frameworks, making them suitable for buyers requiring tailored integration or branding compliance. Dongguan Sammi leads in online transaction volume (US $380,000+), indicating market validation and product reliability, despite a lower on-time delivery rate (88%). Henan Tianzhong stands out for technical responsiveness (≤2h) and full delivery adherence, though its broader machinery focus may affect specialization depth. Shenzhen Yichengxing offers the lowest price points (from $85/unit), ideal for startups or low-throughput operations, but limited revenue scale suggests constrained production capacity.

FAQs

What is the typical MOQ for labelling machines for jars?

Most suppliers list a minimum order quantity (MOQ) of 1 set or unit, enabling pilot testing and small business adoption. Bulk pricing typically applies at 5+ units, with negotiated discounts for larger deployments.

How long does it take to receive a labelling machine?

Lead times range from 7–15 days for standard manual or semi-automatic models. Customized or fully automated systems may require 20–30 days for assembly and calibration. Shipping via air freight adds 5–10 days internationally; sea freight extends transit by 25–40 days.

Can suppliers customize labelling machines for specific jar sizes?

Yes, leading suppliers offer dimensional adjustments for jar diameter, height, and label position. Custom tooling or servo settings can be programmed for oval, square, or tapered containers. Confirmation through pre-shipment testing is recommended.

Do labelling machines support different label materials?

Compatible labels include paper, BOPP, PET, and PVC films. Machines vary in adhesive handling—ensure the model supports your label’s backing type (thermal, pressure-sensitive). Some models require tension adjustment for thin or stretchable substrates.

Are samples available before bulk purchase?

Sample availability depends on supplier policy. Many offer functional demos or video validations. Physical samples may incur fees, often credited toward subsequent orders. Low-cost models (e.g., MT-50, MP-36) are frequently available at near-production pricing for evaluation.