Large Whiskey Ice Cube Maker

CN

CN

Top sponsor listing

Top sponsor listing

About large whiskey ice cube maker

Where to Find Large Whiskey Ice Cube Maker Suppliers?

China remains the dominant manufacturing hub for specialty ice molds and commercial-grade ice-making equipment, with key supplier clusters concentrated in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains specializing in silicone molding, plastic injection, and refrigeration technology, enabling efficient production of large-format ice solutions tailored for premium beverage markets.

Guangdong-based manufacturers leverage proximity to Hong Kong’s logistics network, achieving average export lead times of 25–35 days. Dongguan and Shenzhen facilities specialize in high-precision silicone tooling, supporting complex mold designs such as spherical, cube, and novelty shapes (e.g., skull or golf ball patterns). Jiangsu suppliers, particularly around Nantong, focus on electromechanical ice machines capable of producing 30mm–40mm cubes at volumes up to 40kg per day, catering to commercial bars and hospitality chains.

The industrial ecosystem supports both low-cost manual molds and automated electric systems. Buyers benefit from localized access to raw materials—food-grade platinum-cured silicone, BPA-free plastics, and stainless steel components—reducing material procurement cycles by 15–20%. This integration enables rapid prototyping and scalable production runs, with standard MOQs ranging from 50 to 1,000 units depending on product type.

How to Choose Large Whiskey Ice Cube Maker Suppliers?

Evaluate potential partners using these critical criteria:

Material & Safety Compliance

Confirm use of food-safe materials compliant with FDA, LFGB, and RoHS standards. For silicone products, verify platinum-cured processing over peroxide-based alternatives to ensure odorless, durable performance. Request test reports for BPA, phthalates, and heavy metals, especially for items marketed as reusable or dishwasher-safe.

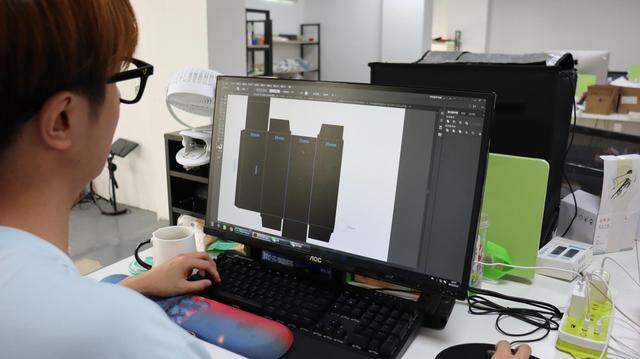

Production Capacity and Customization Capability

Assess technical infrastructure through the following indicators:

- Minimum facility size of 2,000m² for volume orders

- In-house mold design and CNC tooling capabilities

- Customization options including color, logo printing, packaging, and cavity dimensions (e.g., 2-inch cubes or 6cm spheres)

Prioritize suppliers offering vacuum sealing, labeling, and private branding services for direct retail readiness.

Order Fulfillment Metrics

Analyze transactional reliability using verifiable KPIs: target on-time delivery rates above 93%, reorder rates exceeding 25%, and response times under 4 hours. High reorder rates indicate customer satisfaction and consistent quality control. Cross-reference online revenue data where available to assess operational scale.

What Are the Best Large Whiskey Ice Cube Maker Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|

| Jiangmen TW Industry Co., Ltd. | Cake Tools, Ice Cream Tools, Silicone Molds | 100% | 42% | ≤4h | US $40,000+ | Size, shape, color, packaging, logo | 300–1,000 pieces |

| Guangzhou Raybin Homewares Co., Ltd. | Silicone Ice Molds, Reusable Kitchenware | 93% | 26% | ≤2h | US $590,000+ | Color, material, size, label, graphic | 50–100 pieces |

| Dongguan Wiser Silicone & Plastic Co., Ltd. | Silicone Ice Ball Molds, Novelty Shapes | 94% | 30% | ≤13h | US $80,000+ | Logo, shape, size, multi-cavity designs | 100 pieces |

| Nantong Wuding Technology Co., Ltd. | Commercial Ice Machines, Cylinder Ice Systems | 97% | 16% | ≤3h | US $60,000+ | Machine output, voltage, branding | 1 set |

| Protecting Your Electronics (pye) Electronic Technology Co., Ltd. (shenzhen) | Multipurpose Molds, Pet & Kids Dining | 92% | 19% | ≤4h | US $130,000+ | Full OEM/ODM support across design parameters | Varies by product line |

Performance Analysis

Jiangmen TW Industry stands out with a perfect 100% on-time delivery rate and the highest reorder rate (42%), indicating strong process consistency and customer retention. Guangzhou Raybin leads in scalability and responsiveness, supported by a robust online presence and sub-2-hour response time, ideal for fast-turnaround sourcing. Dongguan Wiser offers competitive pricing on novelty designs (e.g., skull-shaped molds) with flexible customization, suitable for niche market positioning. Nantong Wuding specializes in mechanical ice makers rather than molds, targeting commercial clients needing daily outputs of 40kg or more. Shenzhen-based pye Electronics provides broad ODM capabilities but lacks product-specific specialization in barware.

FAQs

What materials are used in large whiskey ice cube makers?

Common materials include food-grade platinum-cured silicone for flexibility and heat resistance (-40°C to 230°C), BPA-free polypropylene (PP) for rigid trays, and stainless steel components in motorized units. Ensure compliance documentation is available for all contact materials.

What is the typical MOQ for custom molds?

MOQs vary by supplier and complexity. Simple silicone molds start at 50–100 pieces; fully branded or multi-cavity designs may require 300–500 units. Electric ice machines typically have an MOQ of 1 set for sample testing.

How long does it take to receive a sample?

Sample production takes 7–15 days for existing molds. Custom tooling adds 10–20 days. Air shipping to North America or Europe requires 5–7 days. Budget 3–5 weeks total for custom samples.

Can suppliers provide private labeling and packaging?

Yes, most suppliers offer full OEM/ODM services including logo embossing, color-matching, retail boxes, instruction cards, and vacuum-sealed packaging. Minimum branding quantities typically start at 100 units.

Are there certifications for ice maker safety?

While no universal certification exists for ice molds, reputable suppliers comply with FDA (USA), LFGB (Germany), and CE (EU) standards for food contact materials. Electrical models should carry CB, CCC, or ETL marks where applicable.