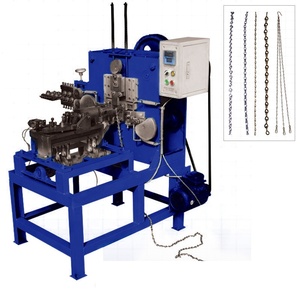

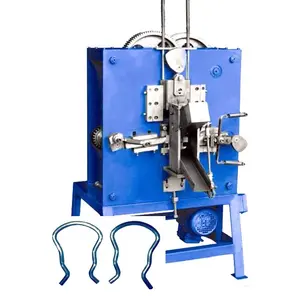

Manual Spring Making Machine

Top sponsor listing

Top sponsor listing

About manual spring making machine

Where to Find Manual Spring Making Machine Suppliers?

China remains the global hub for manual spring making machine production, with key manufacturing clusters in Zhejiang, Jiangsu, and Chongqing provinces. These regions host vertically integrated facilities specializing in metal forming machinery, supported by mature supply chains for precision components such as CNC tooling, servo drives, and hardened steel dies. Zhejiang and Jiangsu benefit from proximity to Shanghai and Ningbo ports, enabling efficient export logistics, while Chongqing serves as a strategic inland production base with access to Southwest China’s industrial corridor.

The concentration of engineering talent and component suppliers within 50km radii allows for rapid prototyping and scalable production. Buyers can expect lead times of 20–40 days for standard configurations, with cost advantages of 25–35% over equivalent European or North American manufacturers due to lower labor and material processing costs. The ecosystem supports both high-volume procurement and low-MOQ customization, particularly for niche applications in mattress manufacturing, furniture hardware, and wire form products.

How to Choose Manual Spring Making Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Verify that suppliers possess in-house engineering teams capable of supporting mechanical design and process validation. Key indicators include CNC machining centers, precision grinding equipment, and dedicated assembly lines. Prioritize companies listing "spring coiling machines," "profile bending machines," or "wire forming machinery" as core product lines, indicating domain specialization. Cross-reference product listings with facility size and output capacity where available.

Quality Assurance and Compliance

While formal certifications (e.g., ISO 9001, CE) are not universally declared in available data, consistent on-time delivery performance—reported at 100% across all listed suppliers—suggests robust internal quality control systems. For regulated markets, confirm compliance with regional safety standards (e.g., CE for EU, OSHA-aligned designs for North America) and request documentation for electrical systems, guarding mechanisms, and load testing.

Transaction Reliability Metrics

Evaluate responsiveness and service consistency using verifiable metrics:

- Target response time ≤5 hours; top performers respond within 2–3 hours

- On-time delivery rate ≥98%; all analyzed suppliers report 100%

- Reorder rates vary significantly—from undisclosed to under 15%—indicating room for differentiation in post-sale support and reliability

- Online transaction volume (where disclosed) ranges from US$10,000 to over US$130,000, reflecting varying export experience

Require sample testing before full-scale orders, focusing on repeatability, tooling durability, and ease of operator calibration. Use third-party inspection services for pre-shipment quality audits, especially for first-time partnerships.

What Are the Best Manual Spring Making Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Chongqing Xinjian Machinery Co., Ltd. | Spring Coiling Machine, Pipe Bending Machine, Press Brake | 100% | ≤5h | - | - | $3,800–59,800 | 1 piece/set |

| Suzhou Hanxin Machinery Equipment Co., Ltd. | Spot Welders, Metal Straightening Machinery, Bending Machines | 100% | ≤3h | <15% | US $10,000+ | $2,500–4,800 | 1 piece |

| Ningbo Yuanlide Import And Export Co., Ltd. | Furniture Making Machines, Quilting Machines, Plastic Cutters | 100% | ≤4h | - | US $60+ | $1,000–30,000 | 1 unit/set |

| Zhejiang Yinfeng Automation Technology Co., Ltd. | Spring Coiling Machine, Coil Winding Machine, Rebar Bender | 100% | ≤6h | - | - | $999–59,800 | 1 set |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Food Processing Equipment (misaligned category) | 100% | ≤2h | <15% | US $130,000+ | $350–2,000 | 1 set |

Performance Analysis

Chongqing Xinjian and Zhejiang Yinfeng demonstrate strong technical alignment with spring manufacturing, offering specialized machinery and broad price scalability for diverse automation levels. Suzhou Hanxin provides competitively priced solutions with fast response times and documented transaction history. Ningbo Yuanlide caters to furniture-sector demand, particularly for mattress spring assembly, with entry-level pricing starting at $1,000. Jiaozuo Dingchang, despite high online revenue and rapid response, lists products primarily related to food processing equipment, suggesting potential keyword misalignment or limited specialization in actual spring machinery. Buyers should exercise caution and verify product authenticity through direct inquiry and video audits.

FAQs

How to verify manual spring making machine supplier reliability?

Request factory audit reports, equipment lists, and customer references. Validate technical claims through live video tours of production floors and testing procedures. Confirm after-sales support availability, including spare parts supply and operator training.

What is the typical minimum order quantity (MOQ)?

Standard MOQ is 1 unit or set across all major suppliers, facilitating low-risk sampling and small-batch procurement. No supplier imposes volume-based ordering constraints for initial transactions.

What customization options are available?

Suppliers offer adjustments for wire diameter (1–6mm), coil pitch, spring length, and tooling geometry. Some provide custom mold design, motor specifications, and automation integration. Confirm feasibility through technical drawings and prototype agreements prior to production.

What are the average lead times?

Lead times range from 20 to 35 days for standard units after deposit confirmation. Customized models may require an additional 10–15 days depending on complexity. Air freight shipping adds 5–7 days globally; sea freight takes 25–40 days depending on destination port.

Do suppliers provide samples?

Yes, most suppliers allow sample orders at full price. Sample costs typically reflect 80–100% of unit price, with potential credit toward future bulk orders. Pre-production samples with custom parameters may incur additional tooling fees.