Morse Code Machine

0

0

1/3

1/3

1/15

1/15

1/3

1/3

0

0

1/25

1/25

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/19

1/19

1/3

1/3

1/14

1/14

1/3

1/3

0

0

1/3

1/3

1/1

1/1

About morse code machine

Where to Find Morse Code Machine Suppliers?

China serves as the central hub for electronic signaling and telegraphy equipment manufacturing, with key production clusters in Shenzhen, Wuhan, and Zhengzhou. These regions host specialized electronics manufacturers that integrate RF module development, embedded firmware engineering, and precision metal fabrication—capabilities critical for producing functional morse code machines. Shenzhen’s Huanqiu Xinrui and Mingweida Electronics leverage proximity to semiconductor suppliers and rapid prototyping facilities, enabling agile production cycles for manual and automatic keying devices.

Industrial coding machine producers such as Wuhan Xiantong Technology and Henan Able Tech operate within broader industrial printing ecosystems, adapting thermal inkjet, TTO (Thermal Transfer Overprint), and laser marking platforms for alphanumeric and signal-based encoding applications. These suppliers benefit from vertically integrated supply chains capable of delivering complete systems—from handheld telegraph keys to automated batch coders—with lead times averaging 15–25 days for standard configurations. The clustering of component vendors, PCB assembly lines, and testing labs within 50km radii supports cost efficiency, with production expenses typically 20–30% below Western counterparts.

How to Choose Morse Code Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm whether the supplier specializes in communication electronics or industrial coding systems. For traditional CW (Continuous Wave) telegraphy equipment, prioritize firms offering dual-paddle keys, auto-keyers, and training modules with frequency stability verification. Industrial coding machine suppliers should demonstrate compliance with IEC 60255 for electrical safety and provide test reports on print head durability, duty cycle ratings, and environmental tolerance (operating temperature, humidity).

Production Infrastructure Assessment

Evaluate core manufacturing assets:

- Minimum factory area of 1,000m² for dedicated electronics or coding machinery lines

- In-house PCB assembly and firmware programming capabilities for trainer devices

- Integration of servo-controlled actuators or solenoid drivers in automatic keying units

Cross-reference product listings with on-time delivery performance (target ≥95%) and response time (ideally ≤2 hours) to assess operational responsiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers with documented quality management systems—even if formal ISO 9001 certification is not listed, consistent on-time delivery (>95%) and low reorder rates (<15%) indicate process discipline. Request sample units to validate build quality, switch actuation life (for telegraph keys), and signal clarity in audio output models.

What Are the Best Morse Code Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Shenzhen Huanqiu Xinrui Electronic Technology Co., Ltd. | Shenzhen, CN | Portable Radio, Wireless Modules, Consumer Electronics | US $50,000+ | 98% | ≤2h | <15% | 1 piece |

| Wuhan Xiantong Technology Co., Ltd. | Wuhan, CN | Inkjet Printers, Laser Marking Machines, Coding Systems | US $170,000+ | 100% | ≤5h | 22% | 1 set |

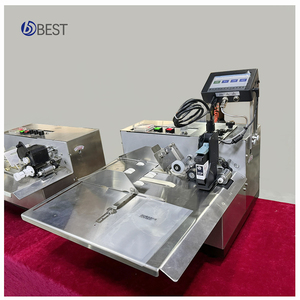

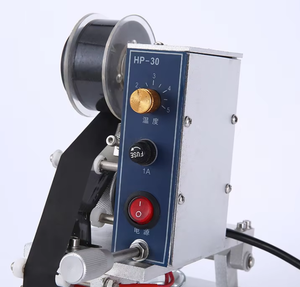

| Henan Able Tech Co., Ltd. | Zhengzhou, CN | Coding Machines, TTO Printers, Hot Stamping Equipment | US $320,000+ | 96% | ≤2h | 23% | 1 box / 1 set |

| Shenzhen Mingweida Electronics Co., Ltd. | Shenzhen, CN | Development Boards, ICs, Communication Modules | US $20,000+ | 95% | ≤2h | <15% | 1 piece (bulk from 5) |

| Jiexi Technology (Shenzhen) Co., Ltd. | Shenzhen, CN | Filling, Labeling, and Coding Machines | US $20,000+ | 97% | ≤3h | <15% | 1 set |

Performance Analysis

Suppliers like Wuhan Xiantong and Henan Able Tech focus on industrial-grade coding systems, offering higher investment thresholds (minimum $499/set) but greater integration potential for automated environments. In contrast, Shenzhen-based firms such as Huanqiu Xinrui and Mingweida specialize in low-cost telegraph keys and training tools, with entry-level pricing as low as $18/unit and MOQs starting at one piece—ideal for educational institutions, hobbyists, or small-scale procurement. High reorder rates at Able Tech (23%) and Xiantong (22%) suggest strong customer satisfaction in industrial segments, whereas sub-15% rates among Shenzhen electronics suppliers reflect transactional, non-recurring buyer behavior. Buyers seeking customization—such as branded key paddles or firmware-modified trainers—should engage suppliers with in-house design teams and request proof of prior OEM projects.

FAQs

How to verify morse code machine supplier reliability?

Validate consistency between product specifications and real-world performance through third-party inspection services. Request evidence of quality control processes, including continuity testing for telegraph circuits, battery life logs, and solder joint inspections. Analyze transaction metrics: suppliers with >95% on-time delivery and response times under 3 hours are more likely to support timely resolution of post-sale issues.

What is the average sampling timeline?

Standard samples for manual telegraph keys or basic trainers ship within 5–7 days. For programmable auto-keyers or integrated training modules, allow 10–14 days due to firmware configuration. Industrial coding machine samples require 15–20 days, including calibration and safety checks.

Can suppliers ship morse code machines worldwide?

Yes, all listed suppliers offer international shipping. Confirm Incoterms (FOB, CIF) and ensure packaging meets drop-test and vibration standards for long-haul transport. For radio-equipped models, verify compliance with destination country regulations on unlicensed transmitter use.

Do manufacturers provide free samples?

Free samples are uncommon. Most suppliers charge 50–100% of unit cost for initial samples, which may be credited toward first bulk orders exceeding 10 units. Low-value components (e.g., key paddles) may incur nominal fees ($5–$10), while full training systems range from $50–$200 per sample unit.

How to initiate customization requests?

Submit detailed technical requirements: desired keying mechanism (manual/dual-paddle/auto-keyer), power source (battery voltage), enclosure material (aluminum/plastic), and firmware features (training modes, speed adjustment). Suppliers with R&D teams will respond with schematics or 3D models within 72 hours. Prototype development typically takes 2–3 weeks for electronic units and 4 weeks for electromechanical coder systems.