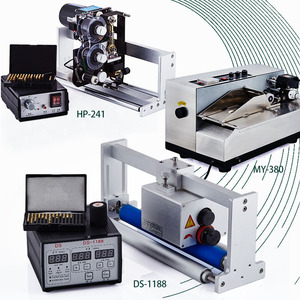

Mrp Batch Coding Machine

Top sponsor listing

Top sponsor listing

1/57

1/57

1/19

1/19

1/16

1/16

1/19

1/19

1/14

1/14

1/15

1/15

1/11

1/11

1/11

1/11

1/10

1/10

1/17

1/17

1/13

1/13

1/18

1/18

About mrp batch coding machine

Where to Find MRP Batch Coding Machine Suppliers?

China remains the central hub for MRP batch coding machine production, with key manufacturing clusters concentrated in Zhejiang, Hubei, and Guangdong provinces. Hangzhou in Zhejiang and Wuhan in Hubei host specialized industrial zones focused on precision printing and marking equipment, offering integrated supply chains for inkjet systems, laser coders, and automated packaging integration components. These regions benefit from mature ecosystems of component manufacturers, R&D centers, and export logistics networks, enabling competitive pricing and rapid scalability.

Suppliers in these clusters typically operate vertically integrated facilities capable of in-house design, assembly, and testing. This structure supports lead times averaging 15–30 days for standard units and 30–45 days for customized configurations. Localized access to electronic controls, print heads, and consumables reduces material costs by 18–25% compared to non-specialized regions. Buyers gain flexibility in output volume, with suppliers accommodating MOQs as low as one unit for handheld models and scalable runs for inline industrial systems.

How to Choose MRP Batch Coding Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

Confirm expertise in core technologies: continuous inkjet (CIJ), thermal inkjet (TIJ), or fiber/CO₂ laser marking. Suppliers should demonstrate compatibility with MRP-integrated workflows, including date, batch number, QR codes, and expiration tracking. Verify support for variable data input, multiple font types, and adjustable print heights (up to 18mm for CIJ systems). For food, pharmaceutical, or beverage applications, ensure compliance with hygienic design standards and non-toxic ink formulations.

Quality & Compliance Verification

Prioritize suppliers with ISO 9001 certification for quality management systems. For exports to regulated markets, CE marking is essential for electrical safety and EMC compliance. Request documentation for component sourcing, particularly for printheads and power supplies. Evaluate after-sales support capacity, including firmware updates, spare parts availability, and remote diagnostics.

Production & Customization Capacity

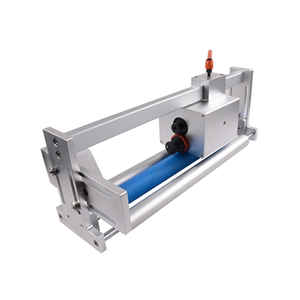

Assess supplier infrastructure through available indicators:

- Facility size and automation level (e.g., conveyor integration, sensor-based triggering)

- In-house engineering teams supporting OEM/ODM customization

- Range of supported substrates (plastic, glass, metal, cardboard) and environmental resilience (dust, moisture, temperature)

Cross-reference online revenue metrics and reorder rates as proxies for market acceptance and service reliability. On-time delivery performance exceeding 94% indicates robust production planning.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services for initial orders. Request physical or digital samples to validate print clarity, durability, and interface usability. Conduct factory audits—virtual or on-site—to verify claimed capabilities. Analyze response times (target ≤4 hours) and communication clarity as indicators of post-sale support efficiency.

What Are the Best MRP Batch Coding Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Hangzhou Dongning Technology Co., Ltd. | Inkjet Printers, Laser Marking Machines, Ink Cartridges | US $200,000+ | 100% | 22% | ≤4h | Yes | Custom Manufacturer |

| Wuhan VZ Information Technology Co., Ltd. | Inkjet Printers, Laser Marking Machines, Coding Machines | US $120,000+ | 88% | 41% | ≤4h | No | - |

| Guangzhou Docod Precision Group Limited | DOD Inkjet Coders, CIJ Printers | US $270,000+ | 100% | 50% | ≤6h | Yes | Custom Manufacturer |

| Henan Best Packing Machine Co., Ltd. | Solid Ink, Hot Stamping, Handheld Printers | US $210,000+ | 94% | 19% | ≤2h | Yes | Multispecialty Supplier |

| Wuhan Xiantong Technology Co., Ltd. | Inkjet Printers, Laser Marking Machines, Coding Machines | US $160,000+ | 100% | 19% | ≤5h | No | - |

Performance Analysis

Guangzhou Docod Precision Group leads in customer retention with a 50% reorder rate, indicating strong satisfaction with product performance and customization capability. Hangzhou Dongning and Wuhan Xiantong achieve perfect on-time delivery records (100%), reflecting disciplined production scheduling. Henan Best Packing Machine stands out for responsiveness (≤2h average), critical for urgent procurement cycles. Suppliers offering customization—particularly in print head configuration, software interface, and integration brackets—demonstrate higher adaptability for complex packaging lines. While Wuhan VZ has a lower on-time delivery rate (88%), its 41% reorder rate suggests effective resolution protocols and product reliability.

FAQs

What certifications should MRP batch coding machines comply with?

Essential certifications include CE for European market access and ISO 9001 for quality management. For food-grade applications, ensure compliance with FDA-approved inks and RoHS directives for restricted substances. Laser models should meet IEC 60825-1 for laser safety classification.

What is the typical minimum order quantity (MOQ)?

Most suppliers offer an MOQ of 1 unit for standard handheld or benchtop models. For fully automated inline systems or OEM-branded units, MOQs may range from 5–10 units depending on customization depth.

How long does customization take?

Custom configurations—including logo integration, language localization, sensor adjustments, or dual-head setups—typically require 25–35 days from approval to shipment. Prototypes can be provided within 10–14 days for validation.

Can these machines integrate with existing production software?

Yes, many models support RS-232, USB, or Ethernet connectivity for synchronization with ERP/MRP systems. Suppliers like Guangzhou Docod and Hangzhou Dongning offer API-level integration for real-time batch data logging and traceability.

What are common printing technologies used?

The primary technologies are Continuous Inkjet (CIJ) for high-speed生产线, Thermal Inkjet (TIJ) for medium-resolution applications, and Fiber/CO₂ Laser for permanent marks on rigid materials. Selection depends on substrate type, environmental conditions, and required code permanence.