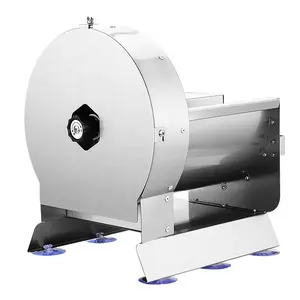

Namkeen Banana Machine

About namkeen banana machine

Where to Find Namkeen Banana Machine Suppliers?

China remains a central hub for food processing equipment manufacturing, with key supplier clusters in Shandong and Henan provinces driving innovation and cost efficiency in the namkeen banana machine sector. Shandong's industrial base features vertically integrated facilities specializing in automated frying systems and multi-stage slicing lines, leveraging proximity to steel and stainless-steel suppliers to reduce material costs by 15–20%. Henan’s machinery ecosystem focuses on compact, energy-efficient models suited for small to mid-scale snack producers, supported by regional expertise in grain and vegetable processing technologies.

These regions offer buyers access to mature supply networks where component sourcing, fabrication, and assembly occur within tightly coordinated zones—often within a 50-kilometer radius. This integration enables faster production cycles, with standard machine lead times averaging 30–45 days. Economies of scale allow suppliers to offer competitive pricing across manual, semi-automatic, and fully automatic configurations, accommodating both entry-level entrepreneurs and large-scale processors targeting export markets.

How to Choose Namkeen Banana Machine Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria to ensure technical reliability and transactional security:

Technical Specifications & Compliance

Verify adherence to international safety and performance benchmarks. While explicit certification data is not provided, prioritize suppliers demonstrating robust build standards using stainless steel components and compliant electrical systems. For operations in regulated markets, confirm compatibility with CE or equivalent safety directives prior to purchase.

Production Capacity Assessment

Evaluate operational scale through available metrics:

- Facility size and workforce indicators (inferred from online revenue and product range)

- Output capacity reflected in machine automation levels—from manual peelers to continuous fryers capable of 300kg/h throughput

- In-house engineering capabilities for customization (e.g., voltage adjustments, output speed tuning)

Cross-reference response time (≤1h to ≤2h observed) and on-time delivery records (up to 100% reported) as proxies for operational discipline.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with shipment and inspection. Review reorder rates—where available—as an indicator of customer satisfaction; suppliers reporting 100% reorder rates suggest strong post-sale support and product durability. Request sample units to validate performance under real-world conditions before scaling procurement.

What Are the Best Namkeen Banana Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shandong Jiate Machinery Technology Co., Ltd. | Shandong, CN | Potato chips making machine, Fryers, Vegetable Cutter | $900–$15,200 | 1 set | 100% | ≤2h | 100% | US $6,000+ |

| GELGOOG CO., LTD | Unknown, CN | Food processing lines, Snack Machines, Yam Chips Equipment | $11,990–$80,000 | 1 set | Not specified | ≤1h | Not specified | Not specified |

| Adan Trading Inc | Unknown, CN | Balers, Candy Machine, Snack Machines | $1,100–$4,800 | 1 set | Not specified | ≤2h | Not specified | Not specified |

| Shandong Newcore Industry Co., Ltd. | Shandong, CN | Fryers, Sausage Stuffer, Meat & Vegetable Machines | $1,600–$12,000 | 1 set | 100% | ≤1h | <15% | US $160,000+ |

| Henan Qinbiao Industrial Development Co., Ltd. | Henan, CN | Grain Product Machines, Fruit Slicers, Oil Pressers | $149 (per piece) | 1–3 pieces | 95% | ≤2h | <15% | US $50,000+ |

Performance Analysis

Shandong-based suppliers demonstrate high reliability, with two companies reporting 100% on-time delivery and strong reorder performance. Shandong Jiate stands out with a verified 100% reorder rate and consistent delivery record, indicating robust quality control and after-sales service. GELGOOG offers the widest range of high-capacity systems, including a 300kg/h fully automatic plantain line priced between $40,000–$80,000, suitable for industrial-scale operations. Henan Qinbiao provides the most accessible entry point with electric slicers at $149/unit, ideal for startups or decentralized production setups. Buyers seeking cost-effective, low-MOQ options may favor Henan-based vendors, while those prioritizing throughput and automation should evaluate Shandong and premium-tier suppliers.

FAQs

How to verify namkeen banana machine supplier reliability?

Assess reliability through documented delivery performance, response consistency, and verifiable transaction volume. Request factory videos or virtual audits to confirm production infrastructure. Validate machine specifications against industry norms for material thickness, motor power, and thermal efficiency.

What is the typical lead time for banana machine orders?

Standard units are typically delivered within 30–45 days after order confirmation. Customized or fully automated lines may require 60+ days depending on complexity and component availability.

Can suppliers accommodate custom voltage or automation requirements?

Yes, many suppliers offer customization for electrical specifications (e.g., 220V/380V), cutting thickness, and integration with existing production lines. Confirm modification capabilities during initial inquiry and request technical drawings for validation.

Do manufacturers provide samples for testing?

Sample availability varies. Some suppliers offer single-unit purchases (e.g., $149 per slicer), enabling functional evaluation. For larger systems, expect partial sampling fees that may be credited toward bulk orders.

What are common packaging and shipping methods?

Machines are typically crated in wooden enclosures for sea freight, with optional containerization for full-line shipments. Confirm FOB terms and coordinate logistics partners early to manage import clearance, especially for heavy or powered equipment subject to electrical compliance checks.