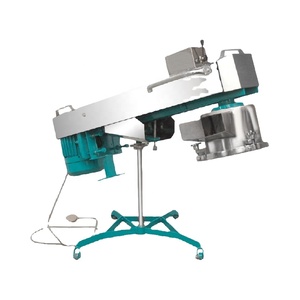

Namkeen Dry Machine

1/13

1/13

1/34

1/34

1/11

1/11

1/6

1/6

1/10

1/10

1/31

1/31

About namkeen dry machine

Where to Find Namkeen Dry Machine Suppliers?

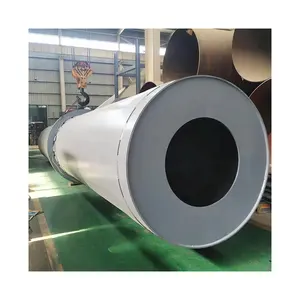

China leads global manufacturing of industrial drying equipment, with key supplier clusters in Guangdong, Chongqing, and Henan provinces. These regions host vertically integrated production ecosystems specializing in food processing machinery, including dedicated lines for namkeen and snack dehydration systems. Guangzhou-based manufacturers leverage proximity to port infrastructure and a mature supply chain for stainless steel components, reducing logistics lead times by 15–20% compared to inland producers. Chongqing’s electromechanical industrial base enables advanced integration of air-drying and filtration technologies, while Henan’s machinery corridor supports high-volume output through cost-efficient casting and fabrication networks.

Suppliers in these zones typically operate multi-disciplinary facilities capable of producing batch and continuous-flow dryers, ranging from compact tabletop units to large-scale tunnel dehydrators. The concentration of component vendors—such as fan assemblies, heating elements, and control panels—within 50 km allows rapid prototyping and assembly. Buyers benefit from shorter production cycles (average 25–40 days for standard configurations), localized sourcing of raw materials, and flexibility in MOQs, with many suppliers accommodating single-unit trials for international clients.

How to Choose Namkeen Dry Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance and Equipment Design

Verify adherence to international safety and performance standards such as CE or ISO 9001, particularly for electrical systems and thermal controls. Assess machine specifications for uniform airflow distribution, temperature precision (±2°C), and material contact compliance (e.g., SUS304 stainless steel chambers). Request documentation on motor efficiency, energy consumption rates, and noise levels (ideally below 75 dB).

Production Capability Verification

Evaluate the following indicators of manufacturing maturity:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams supporting customization (e.g., adjustable trays, PLC controls, humidity sensors)

- Integrated testing protocols, including load trials and thermal calibration

- Cross-reference on-time delivery performance (target ≥95%) with order volume history

Transaction Security and After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery service frameworks. Confirm availability of technical manuals, spare parts inventories, and remote troubleshooting support. For customized units, require sample validation before full production release. Conduct video audits of assembly lines to verify claimed capabilities and quality control checkpoints.

What Are the Best Namkeen Dry Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Mumbai, IN | Snack Machines, Flour Mill, Food Processing Machinery | Not specified | Not specified | ≤6h | Not specified | 1 piece/unit | $340–445 |

| Chongqing Nakin Electromechanical Co., Ltd. | Chongqing, CN | Drying Equipment, Oil Purifiers, Filtration Systems | US $2,000+ | 100% | ≤2h | <15% | 1 set | $3,500–15,000 |

| Drytech (Guangzhou) Technology Co., Ltd. | Guangzhou, CN | Fruit & Vegetable Dryers, Pasta/Noodle Dryers, Pet Food Machinery | US $120,000+ | 100% | ≤10h | 33% | 1 set | $6,000 |

| Henan Flysun Machinery Manufacturing Co., Ltd. | Henan, CN | Drying Equipment, Waste Treatment, Briquette Machines | US $200,000+ | 83% | ≤4h | <15% | 1 set | $1,280–26,000 |

| Guangzhou Ikeme Technology Co., Ltd. | Guangzhou, CN | Laboratory & Home-Use Drying, Sterilizing Equipment | US $150,000+ | 98% | ≤3h | <15% | 1 unit/set | $291.70–2,423 |

Performance Analysis

Chongqing Nakin and Drytech Guangzhou demonstrate strong reliability with 100% on-time delivery and established export histories, making them suitable for time-sensitive procurement. Drytech stands out with a 33% reorder rate, indicating customer satisfaction in the food dehydration niche. Henan Flysun offers broad pricing tiers but lower fulfillment consistency (83% on-time), suggesting potential bottlenecks in order management. LEENOVA provides entry-level pricing ideal for small-scale operations, though limited transaction data constrains risk assessment. Guangzhou Ikeme caters to hybrid markets with lab-grade units, enabling dual-use applications in R&D and commercial settings.

FAQs

How to verify namkeen dry machine supplier credibility?

Validate certifications through issuing bodies and request evidence of past shipments via bill of lading samples. Conduct virtual factory tours to assess production workflows and quality checks. Analyze buyer reviews focusing on equipment durability and responsiveness to technical queries.

What is the typical lead time for drying machines?

Standard models ship within 20–30 days after order confirmation. Customized systems with PLC integration or non-standard dimensions may require 45–60 days, depending on complexity. Air freight adds 5–10 days globally; sea freight ranges from 25–45 days based on destination port.

Can suppliers accommodate OEM/ODM requests?

Yes, multiple suppliers offer customization options including color, branding (logo/packaging), tray count, voltage configuration (110V/220V), and control panel language. Minimum order thresholds for branding typically start at 5 units, though some accept single-piece personalization at a premium.

Are samples available before bulk ordering?

Sample policies vary: some suppliers provide functional units at full price with credit toward future orders, while others exclude samples for heavy machinery due to shipping costs. Clarify return terms and testing periods prior to dispatch.

What are common packaging and export practices?

Machines are typically crated in seaworthy wooden enclosures with anti-vibration padding and moisture barriers. Suppliers should provide packing lists, export declarations, and compatibility with containerized shipping (20ft or 40ft). Confirm inclusion of installation guides and recommended spare parts kits.