Namkeen Processing Machine

CN

CN

CN

CN

CN

CN

CN

CN

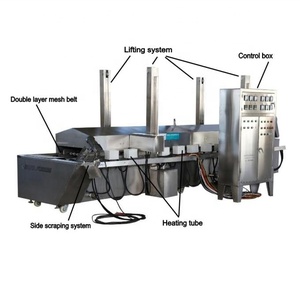

About namkeen processing machine

Where to Find Namkeen Processing Machine Suppliers?

India and China dominate the global supply of namkeen processing machinery, with concentrated manufacturing hubs offering distinct competitive advantages. Indian suppliers, particularly in Gujarat and Maharashtra, specialize in compact, energy-efficient machines tailored for small to mid-scale snack producers. These regions benefit from deep integration with local spice and flour industries, enabling optimized machine design for regional recipes such as gathiya, sev, and nimki.

Chinese manufacturers, primarily based in Henan and Guangdong provinces, focus on fully automated, high-capacity production lines. These industrial clusters feature vertically integrated ecosystems—spanning stainless steel fabrication, control system assembly, and thermal engineering—allowing rapid prototyping and scalable output. Buyers gain access to advanced fryers, seasoning drums, and ribbon blenders with CE-compliant electrical systems and 304-grade stainless steel construction. Lead times average 25–40 days for standard units, with cost efficiencies of 20–35% compared to European or North American equivalents due to localized component sourcing and lower labor inputs.

How to Choose Namkeen Processing Machine Suppliers?

Prioritize these verification protocols when evaluating potential partners:

Technical Compliance & Build Quality

Confirm use of food-grade materials (e.g., SS304 or SS316) in contact zones and compliance with international safety standards such as CE or IEC for electrical components. Request documentation on motor specifications (IP rating, power source), temperature control accuracy, and oil filtration systems where applicable. Machines designed for continuous operation should include overheat protection and corrosion-resistant coatings.

Production Capability Assessment

Evaluate supplier infrastructure through available metrics:

- Facility size exceeding 2,000m² indicating capacity for batch production

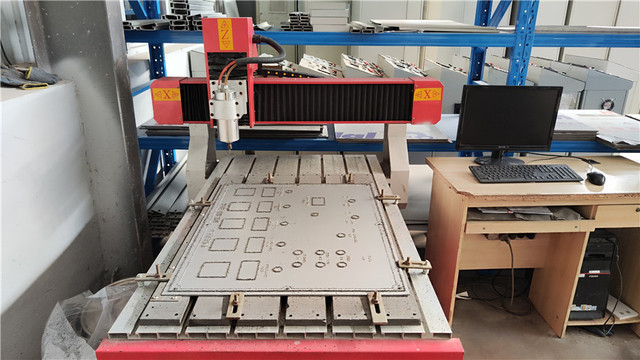

- In-house engineering teams supporting customization (e.g., voltage adjustments, feed rate modifications)

- Integration of PLC controls and automation features in higher-tier models

Cross-reference response time data (target ≤6 hours) and on-time delivery performance (ideal ≥95%) as indicators of operational reliability.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers offering post-delivery technical guidance, including installation videos or remote troubleshooting. Verify availability of spare parts and service documentation in English or target language. Sample testing is recommended—assess oil consumption rates, product consistency, and cleaning efficiency before scaling procurement.

What Are the Best Namkeen Processing Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Customization | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | India | Namkeen making machines, dryers, ribbon blenders | $310–$1,220 | 1 piece/unit | Data not available | ≤6h | Limited | Data not available |

| Henan Gelgoog Machinery Co., Ltd. | Henan, CN | Automatic fryers, continuous namkeen lines | $3,400–$15,000 | 1 set | 100% | ≤1h | Yes (material, size, logo) | <15% |

| Guangzhou Gelgoog Foods Co., Ltd. | Guangdong, CN | Fryers, flavoring systems, plantain processing lines | $6,000–$98,800 | 1 set | 100% | ≤2h | Yes (packaging, labeling, configuration) | <15% |

| Shijiazhuang Jiayue Machinery Manufacturing Co., Ltd. | Hebei, CN | Continuous fryers, flavoring machines | $4,600–$28,000 | 1 set | 100% | ≤15h | No explicit mention | Data not available |

| PLATINA OVERSEAS | India | Namkeen makers, dryers, masala grinders | $200–$250 | 1 piece | Data not available | ≤7h | No explicit mention | Data not available |

Performance Analysis

Chinese manufacturers like Henan Gelgoog and Guangzhou Gelgoog offer full-line automation with verified on-time delivery and robust customization options, making them suitable for large-scale export-oriented operations. Their pricing reflects investment in durability and throughput, with multi-machine sets supporting end-to-end processing. Indian suppliers such as LEENOVA and PLATINA provide entry-level equipment at competitive price points ($200–$1,220), ideal for startups or regional vendors requiring single-function units. While response times are generally fast across both geographies, Chinese firms demonstrate stronger performance tracking and process transparency. For mission-critical deployments, prioritize suppliers with documented quality management practices and proven experience in international shipping.

FAQs

How to verify namkeen processing machine supplier reliability?

Request evidence of material certifications (e.g., SS304 test reports), electrical compliance (CE/IEC), and factory audit summaries. Analyze transaction history for consistency in order fulfillment and customer communication. Third-party inspection services can validate machine build quality prior to shipment.

What is the typical MOQ and lead time?

MOQ ranges from 1 piece for standalone units to 1 set for integrated lines. Standard lead times vary between 20–45 days depending on complexity and customization level. Simple electric dryers may ship within 15 days, while gas-powered continuous fryers require 30+ days for assembly and testing.

Can suppliers customize voltage and phase requirements?

Yes, most established manufacturers support customization for 220V/380V, 50Hz/60Hz, and single/three-phase configurations. Confirm compatibility with local grid standards before ordering, especially for automated control panels.

Do namkeen machines support multiple snack types?

Many models are adaptable across products like gathiya, sev, bhujia, and chakli via interchangeable dies and adjustable speed settings. However, dedicated lines for specific snacks (e.g., onion rings or samosas) may require specialized tooling and separate units.

Are samples available before bulk purchase?

Sample policies differ by supplier. Some offer functional demos via video, while others provide physical units at full or partial cost. Expect sample fees to be credited toward larger orders (typically 5+ units). Clarify return terms and shipping responsibilities upfront.