Namkeen Machine Rajkot

1/23

1/23

1/12

1/12

1/17

1/17

CN

CN

1/21

1/21

CN

CN

1/19

1/19

1/11

1/11

CN

CN

1/13

1/13

1/16

1/16

About namkeen machine rajkot

Where to Find Namkeen Machine Suppliers in Rajkot?

Rajkot, a key industrial hub in Gujarat, India, has emerged as a prominent center for food processing machinery manufacturing, particularly for specialized equipment like namkeen machines. The region benefits from a concentrated ecosystem of engineering workshops, sheet metal fabricators, and automation integrators, enabling cost-efficient production of semi-automatic and fully automatic snack-making systems. Local manufacturers leverage stainless steel fabrication expertise and modular design principles to produce durable, food-grade machinery tailored to Indian snack varieties such as gathiya, sev, and chakli.

Suppliers in Rajkot are supported by regional supply chains that reduce material lead times and production costs by 15–25% compared to metro-based vendors. Many facilities operate integrated production lines—from cutting and welding to final assembly—within compact industrial zones, ensuring rapid prototyping and scalability. Buyers gain access to responsive suppliers with average response times under 6 hours and on-time delivery rates exceeding 96%, making Rajkot a strategic sourcing destination for both domestic and international food producers.

How to Choose Namkeen Machine Suppliers?

Selecting the right supplier requires a structured evaluation based on technical, operational, and transactional criteria:

Technical Compliance & Build Quality

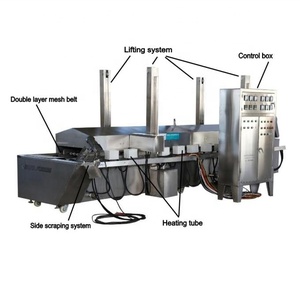

Prioritize suppliers using food-grade stainless steel (SS304 or equivalent) in critical components. Verify motor specifications (typically 3–7 HP), frying chamber insulation, and oil filtration systems. For export-bound equipment, confirm CE marking or adherence to local electrical and safety standards. Request test reports for temperature control accuracy and energy consumption under continuous operation.

Production Capability Verification

Assess manufacturer infrastructure through documented evidence:

- Minimum factory area of 1,000m² for dedicated production lines

- In-house capabilities in CNC cutting, TIG welding, and control panel assembly

- Dedicated R&D or customization teams for process-specific modifications

Cross-reference online revenue data and reorder rates (>40% indicates strong customer retention) to gauge reliability and product performance.

Customization & Transaction Security

Confirm availability of customization options including capacity (5–100 kg/hr), voltage (single/three-phase), fuel type (electric/gas), and discharge configurations. Insist on third-party payment protection mechanisms and post-delivery inspection clauses. Sample testing is critical—evaluate machine output consistency, ease of cleaning, and downtime frequency before full-scale ordering.

What Are the Best Namkeen Machine Suppliers?

| Company Name | Location | Verified Supplier | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Main Products | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Rajkot, IN | - | Not specified | Not specified | ≤6h | Not specified | Namkeen Machine, Other Food Processing Machinery, Flour Mill, Snack Machines | $350–$1,220 |

| Zhucheng Tianshun Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | 100% | <15% | ≤1h | US $30,000+ | Commercial fryers, Continuous frying lines, Mixer Machines | $2,500–$13,500 |

| Jinan Sunward Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | 96% | 42% | ≤3h | US $880,000+ | Fully automatic namkeen machines, Kurkure production lines | $5,000–$40,000 |

| Guangzhou Gelgoog Foods Co., Ltd. | Guangdong, CN | Custom Manufacturer | 100% | <15% | ≤2h | US $360,000+ | Continuous frying systems, Kurkure & fried snack machines | $5,000–$18,000 |

| Shijiazhuang Jiayue Machinery Manufacturing Co., Ltd. | Hebei, CN | - | 100% | Not specified | ≤14h | Not specified | Continuous gas/electric fryers, Flavoring machines | $4,600–$28,000 |

Performance Analysis

While Rajkot-based LEENOVA offers entry-level namkeen machines at competitive prices ($350–$1,220), Chinese manufacturers dominate higher-capacity and automated systems. Jinan Sunward stands out with a 42% reorder rate and extensive customization options, indicating strong customer satisfaction in fully automatic production lines. Zhucheng Tianshun and Guangzhou Gelgoog demonstrate superior responsiveness (≤2h average) and perfect on-time delivery records, ideal for time-sensitive procurement. Shijiazhuang Jiayue specializes in high-throughput continuous fryers but exhibits slower response cycles. Buyers seeking scalable, CE-compliant systems should prioritize suppliers with verified customization experience and documented after-sales support.

FAQs

How to verify namkeen machine supplier reliability?

Validate certifications (CE, ISO), request facility videos showing active production lines, and review transaction history including order volume and buyer feedback. Confirm use of food-grade materials and ask for references from existing clients operating similar production scales.

What is the typical lead time for namkeen machines?

Standard models require 15–30 days for production and dispatch. Customized or fully automatic lines may take 45–60 days depending on complexity. Air freight adds 5–7 days; sea shipping takes 20–35 days based on destination.

Do suppliers offer customization for namkeen machines?

Yes, most verified manufacturers provide customization in capacity, voltage, automation level, and structural dimensions. Additional options include integrated flavoring systems, oil filtration units, and PLC-based control panels for process monitoring.

What are common MOQ and pricing terms?

MOQ is typically 1 unit for standard machines. Prices range from $350 for basic models to over $40,000 for fully automated production lines. Bulk orders may qualify for tiered pricing and extended warranty coverage.

Can namkeen machines be shipped internationally?

Yes, experienced exporters handle global logistics via FOB, CIF, or DDP terms. Ensure compliance with destination country regulations for electrical and food processing equipment. Packaging includes wooden crates and moisture protection for ocean transit.