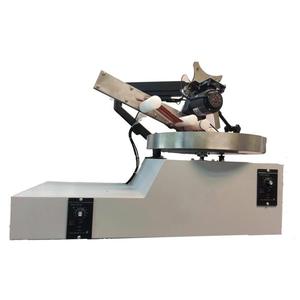

Oritha String Hopper Machine

1/25

1/25

1/21

1/21

1/6

1/6

1/9

1/9

1/13

1/13

1/32

1/32

1/3

1/3

1/14

1/14

About oritha string hopper machine

Where to Find Oritha String Hopper Machine Suppliers?

Manufacturers of string hopper machines, including models associated with the term "Oritha," are primarily concentrated in industrial hubs across China, particularly in Henan, Shandong, and Fujian provinces. These regions host vertically integrated supply chains that support efficient production of food processing and material handling equipment. Henan and Shandong specialize in automated machinery systems with access to robust metalworking infrastructure, while Fujian-based exporters focus on compact, stainless steel consumer-grade models suited for commercial kitchens and small-scale operations.

The clustering of component suppliers, fabrication workshops, and logistics networks within 50km radii enables rapid prototyping and assembly. This ecosystem supports competitive pricing, with standard units starting as low as $30 for basic dryers and reaching up to $9,300 for industrial nonwoven or feed processing systems incorporating hopper mechanisms. Lead times typically range from 15–30 days depending on customization level, with many suppliers offering modular designs adaptable to different throughput requirements.

How to Choose Oritha String Hopper Machine Suppliers?

Selecting reliable manufacturers requires a structured evaluation based on technical capability, operational transparency, and transactional reliability.

Technical & Material Specifications

Confirm construction materials—304 stainless steel is standard for hygienic applications such as food-grade string hoppers. For industrial drying or feeding systems, verify compatibility with target materials (e.g., plastic granules, animal feed, textile fibers). Demand detailed schematics for critical components like conical funnels, vibration controls, and moisture extraction systems where applicable.

Production Capacity Verification

Assess manufacturing scale through objective indicators:

- Facility size exceeding 2,000m² indicates capacity for batch production

- In-house CNC machining and welding capabilities ensure quality control

- Dedicated R&D teams suggest adaptability for custom configurations

Cross-reference declared output volumes with order history and delivery performance metrics.

Quality Assurance & Compliance

While explicit ISO certification data is not available in public profiles, prioritize suppliers demonstrating consistent on-time delivery (≥94%) and documented response times under 8 hours. Request evidence of internal quality checks, especially for pressure-tested stainless steel welds and electrical safety standards if motorized components are involved.

What Are the Best Oritha String Hopper Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Henan Jingjiang Industrial Automation Co., Ltd. | Henan, CN | Caster Wheels, Conveyors, Material Handling Parts | $30–$1,500 | 1 box/piece | 100% | ≤1h | 21% | $60,000+ |

| Taian Jiyi Machinery Equipment Co., Ltd. | Shandong, CN | Feed Processing Machines, Pet Food Equipment | $350–$1,250 | 1 set | 100% | ≤2h | 29% | $80,000+ |

| Xiamen Seasoar Import & Export Co., Ltd. | Fujian, CN | Meat Tools, BBQ Equipment, Home Utensils | $66.40–$110 | 100–200 pieces | 100% | ≤3h | - | - |

| Changshu Huaxin Nonwoven Machinery Technology Co., Ltd. | Jiangsu, CN | Nonwoven Machines, Mask Making Lines | $9,188–$9,300 | 1 set | 100% | ≤8h | - | - |

| Shenzhen Gelinshi Sport Equipment Co., Ltd. | Guangdong, CN | Tennis & Badminton Stringing Machines | $380–$410 | 1 set | 94% | ≤7h | <15% | $70,000+ |

Performance Analysis

Suppliers vary significantly by application focus. Taian Jiyi and Henan Jingjiang offer mid-range industrial solutions with strong reorder rates (29% and 21%, respectively), indicating customer retention in niche automation sectors. Xiamen Seasoar targets consumer markets with lower-priced manual string hoppers, requiring higher MOQs (100+ units) but providing cost-effective options for distributors. Changshu Huaxin represents the high-end segment, specializing in large-scale nonwoven production lines integrating advanced hopper feeders, though with limited responsiveness. Shenzhen Gelinshi serves a specialized sports equipment niche, suggesting potential misalignment with general-purpose hopper needs despite keyword overlap. Buyers should align supplier selection with intended use—commercial kitchen, plastics processing, or textile manufacturing—to avoid functional mismatches.

FAQs

How to verify oritha string hopper machine supplier reliability?

Evaluate on-time delivery records (target ≥97%), average response time (ideally ≤2h), and transaction volume. Request product specifications, material certifications, and, if possible, third-party inspection reports. Video audits of production lines can confirm claimed capabilities.

What is the typical minimum order quantity (MOQ)?

MOQ varies by supplier and model type: industrial systems often require 1 set, while consumer-grade units may require 100–200 pieces. Some suppliers offer single-box trials for select items, particularly dryers and simple funnels.

Are customization options available?

Yes, several suppliers list OEM/ODM services, particularly for mechanical design, branding, and dimensional adjustments. Confirm feasibility directly with engineering teams and request prototypes before mass production.

What are common lead times for production and shipping?

Production lead time averages 15–30 days post-deposit. Air freight adds 5–10 days for samples; sea freight for bulk orders takes 20–40 days depending on destination port and customs procedures.

Do suppliers provide technical documentation?

Reputable manufacturers supply operation manuals, assembly diagrams, and maintenance guidelines. For regulated industries, request compliance documentation related to material safety, electrical standards, or hygiene certifications upon inquiry.