Best String Hopper Maker

TW

TW

About best string hopper maker

Where to Find String Hopper Maker Suppliers?

China remains the central hub for industrial hopper manufacturing, with key production clusters in Shandong and Henan provinces. These regions host vertically integrated facilities specializing in metal fabrication, automated assembly, and bulk material handling systems. Shandong's Taian and Qingdao zones are known for feed and agricultural processing equipment, supported by mature supply chains for stainless steel and pelletizing components. Henan’s Zhengzhou corridor excels in construction and concrete-related machinery, enabling cross-sector engineering expertise applicable to high-capacity hoppers.

The concentration of component suppliers, CNC workshops, and logistics networks within 50km radii allows for rapid prototyping and scalable production. Manufacturers in these zones typically operate from facilities exceeding 5,000m², achieving lead times of 20–40 days for standard orders. Localized sourcing reduces raw material costs by 15–25% compared to non-specialized regions, while established export channels support containerized shipping to global markets. Buyers benefit from flexible MOQs, ranging from single sets for testing to full-line deployments.

How to Choose String Hopper Maker Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to ISO 9001 standards for quality management as a baseline. For food-grade or animal feed applications, verify use of rust-resistant materials (e.g., SS304/SS316) and compliance with hygiene design principles. Request documentation on welding integrity, load capacity testing, and surface finishing processes.

Production Capability Verification

Assess core infrastructure indicators:

- Minimum factory area of 3,000m² to ensure volume capacity

- In-house capabilities in laser cutting, bending, and automated welding

- Dedicated R&D or customization teams for tailored discharge configurations

Cross-reference online revenue data and reorder rates to gauge market acceptance and reliability.

Transaction Risk Mitigation

Prioritize suppliers with verifiable on-time delivery records (target ≥95%) and response times under 3 hours. Utilize secure payment mechanisms such as escrow services until post-delivery inspection. Conduct sample testing to validate structural durability, flow efficiency, and dimensional accuracy before scaling procurement.

What Are the Best String Hopper Maker Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Taian Jiyi Machinery Equipment Co., Ltd. | Feed Processing Machines (486) | $350–$1,250 | 1 set | 100% | ≤3h | 35% | Material, capacity, configuration | US $80,000+ |

| Zhengzhou Wanshan Machinery Manufacturing Co., Ltd. | Concrete Mixers, Hoppers | $130–$280 | 1 set | 86% | ≤2h | 18% | Size, color, discharge type, logo | US $100,000+ |

| Zhengzhou Jingcheng Machinery Equipment Co., Ltd. | Concrete Mixers (373) | $180–$200 | 1 set | 100% | ≤1h | 16% | Capacity, mobility, structure | US $20,000+ |

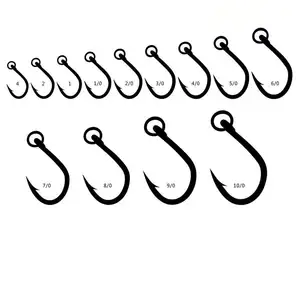

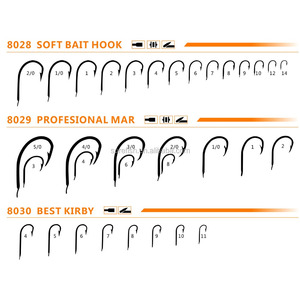

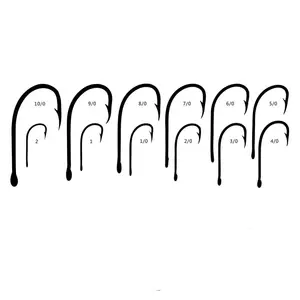

| Hangzhou Top Right Import & Export Co., Ltd. | Fishing Lures, Soft Baits | $0.70–$2.90 | 2–20 pieces | 100% | ≤3h | 18% | Bait design, weight, packaging | US $110,000+ |

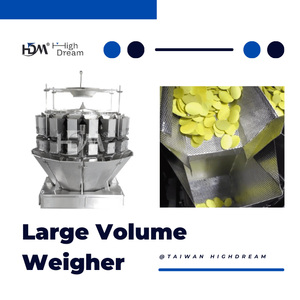

| TAIWAN HIGHDREAM INTELLECTUALIZED MACHINERY CO., LTD. | Automated Food Processing Lines | $10,000–$26,800 | 1 set | 100% | ≤12h | - | System integration, feeder, weigher | - |

Performance Analysis

Taian Jiyi stands out with a 35% reorder rate and full on-time delivery, indicating strong customer retention in the feed machinery segment. Zhengzhou Wanshan offers competitive pricing and fast response times but has a lower delivery performance (86%), suggesting potential logistical constraints. Zhengzhou Jingcheng combines reliability (100% on-time) with sub-hour responsiveness, ideal for urgent procurement cycles. Hangzhou Top Right operates in a niche baitware segment with low unit costs and high customization, though not aligned with industrial hopper systems. TAIWAN HIGHDREAM provides high-end automated solutions for food processing, with large-scale systems suited for enterprise buyers requiring integrated feeding mechanisms.

FAQs

How to verify string hopper maker reliability?

Cross-check ISO certifications and request evidence of past project deliveries. Analyze supplier tags for consistent on-time performance, response speed, and customization breadth. Review product listings for technical detail depth, including material specs, load ratings, and assembly diagrams.

What is the typical lead time for custom hopper systems?

Standard units ship within 15–25 days. Custom-engineered models with specific discharge angles, multi-compartment designs, or automation integration require 30–50 days, depending on complexity and factory workload.

Can suppliers provide OEM/ODM services?

Yes, most manufacturers listed offer OEM labeling, logo imprinting, and packaging customization. Advanced options include structural modifications, color finishes, and capacity tuning—subject to minimum order thresholds.

Are samples available before bulk ordering?

Sample policies vary: some suppliers offer functional prototypes at 30–50% above unit cost, refundable against future orders. For small components (e.g., fishing-related hoppers), free samples may be available for evaluation.

What materials are commonly used in string hopper construction?

Industrial models use carbon steel with anti-rust coating or stainless steel (SS304/SS316) for corrosion resistance. Lightweight consumer variants may employ reinforced ABS or polyethylene, particularly in non-industrial applications like bait dispensers.