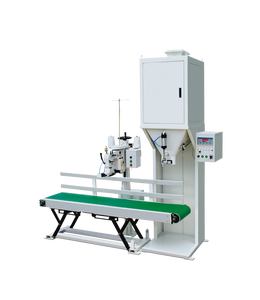

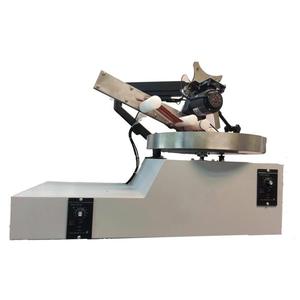

String Hopper Machine

1/25

1/25

1/15

1/15

1/43

1/43

1/50

1/50

1/22

1/22

1/9

1/9

About string hopper machine

Where to Find String Hopper Machine Suppliers?

China's industrial hubs in Henan and Guangdong provinces are central to the production of string hopper machines, with concentrated clusters offering integrated supply chains and specialized manufacturing expertise. Zhengzhou in Henan has emerged as a key center for food processing and material handling equipment, hosting suppliers with access to advanced metal fabrication and automation components. Dongguan in Guangdong specializes in precision electromechanical systems, supporting high-efficiency hopper loading and feeding machinery used across plastics, food, and construction industries.

These regions benefit from vertically integrated ecosystems where raw material sourcing, CNC machining, welding, and final assembly occur within compact geographic zones—reducing lead times by up to 25%. Suppliers in these areas typically maintain agile production lines capable of fulfilling both standardized and customized orders within 15–30 days. Buyers gain access to competitive pricing models driven by localized steel, stainless steel, and motor component availability, with average cost advantages of 20–35% over Western manufacturers.

How to Choose String Hopper Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Material Standards

Verify that equipment is constructed using food-grade stainless steel (for food applications) or carbon steel with anti-corrosion treatment (industrial use). Demand documentation on motor specifications, load capacity, and structural integrity. For export compliance, ensure alignment with regional safety standards such as CE (Europe) or NEMA (North America), particularly for electrically powered units.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Facility size exceeding 2,000m² indicating scalable operations

- In-house engineering teams supporting customization (e.g., hopper volume, feed rate, voltage)

- Integrated fabrication capabilities including laser cutting, bending, and automated welding

- Minimum monthly output capacity of 50+ units for consistent inventory turnover

Cross-reference online revenue data and reorder rates as indicators of market trust. Prioritize suppliers with response times under 6 hours and on-time delivery performance above 98%.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Request sample testing before bulk procurement—assess durability, filling accuracy, and ease of cleaning. Confirm post-delivery support availability, including spare parts supply and technical troubleshooting. Review customer feedback focusing on long-term machine reliability and service responsiveness.

What Are the Best String Hopper Machine Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Junlan Machinery Equipment Co., Ltd. | Henan, CN | Meatball forming machines, grain processors, food lines | Not specified | 100% | ≤5h | US $20,000+ | 25% | $60/set |

| Zhengzhou Jingteng Machinery Equipment Co., Ltd. | Henan, CN | Tower crane hoppers, concrete mixers, mortar pumps | Not specified | 100% | ≤2h | US $10,000+ | 16% | $140/set |

| Dongguan Mingkai Electromechanical Co., Ltd. | Guangdong, CN | Plastic pellet hoppers, vacuum drying systems, extruder loaders | Material, color, capacity, motor power, logo | 98% | ≤2h | US $610,000+ | 21% | $100/set (2 sets min.) |

| Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. | Hubei, CN | Rice milling systems, automatic packing machines | Not specified | 100% | ≤6h | US $20,000+ | <15% | $3,880/set |

| Puyang Yimida Precision Automation Co., Ltd. | Henan, CN | Stainless steel hoppers, filling machines | Color, material, size, packaging, graphic | 100% | ≤2h | US $50,000+ | <15% | $52/dozen (2 dozen min.) |

Performance Analysis

Dongguan Mingkai leads in customization depth and sales volume, with extensive options for industrial adaptation and the highest reported online revenue. Its 98% on-time delivery rate reflects strong production control despite complex order configurations. Zhengzhou-based suppliers dominate responsiveness, with three companies achieving sub-5-hour average reply times—critical for urgent sourcing cycles. Puyang Yimida offers the lowest entry point at $52 per dozen for basic string hopper variants, making it suitable for low-budget procurement. Wuhan Dingxin serves niche markets requiring dual-hopper packaging integration but commands significantly higher minimum investments. All top-tier suppliers demonstrate perfect or near-perfect on-time delivery records, underscoring operational discipline in China’s core machinery belts.

FAQs

What materials are commonly used in string hopper machines?

Stainless steel (SS304 or SS316) is standard for food-grade and corrosion-resistant applications. Carbon steel with powder coating is typical for industrial material handling. Plastic-lined hoppers may be used for lightweight, non-abrasive materials.

What is the typical MOQ for string hopper machines?

Minimum order quantities vary: individual units (1–2 sets) are common for high-value machines, while lower-cost models may require 2–5 dozen units. Customized designs often mandate higher MOQs depending on tooling investment.

Are customization options available?

Yes, leading suppliers offer modifications in capacity, motor power, voltage, discharge configuration, and branding. Dongguan Mingkai and Puyang Yimida provide comprehensive design flexibility, including material selection and graphic labeling.

What are the average lead times?

Standard models ship within 10–20 days after order confirmation. Custom-engineered units require 25–40 days, depending on complexity. Air freight adds 7–10 days globally; sea freight ranges from 20–45 days based on destination.

Do suppliers support global shipping?

Yes, all listed suppliers have international transaction experience. Confirm Incoterms (FOB, CIF, DDP) during negotiation. Most work with third-party logistics providers to manage customs clearance and last-mile delivery.