String Hopper Machine Daraz

1/25

1/25

1/15

1/15

1/25

1/25

1/27

1/27

1/33

1/33

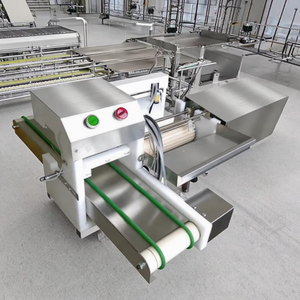

About string hopper machine daraz

Where to Find String Hopper Machine Suppliers?

China remains the central hub for string hopper machine manufacturing, with key production clusters in Shandong, Guangdong, and Fujian provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable output across industrial automation, food processing, and material handling equipment. Shandong and Fujian are particularly notable for stainless steel fabrication expertise, enabling durable, corrosion-resistant hopper designs essential for hygienic or high-throughput environments.

The concentration of component suppliers—such as vibratory feeders, drying systems, and control panels—within 50km radii allows manufacturers to streamline assembly and reduce lead times by up to 25%. Buyers benefit from competitive pricing due to localized sourcing, with average unit costs ranging from $59 to $2,300 depending on automation level and capacity. Standard delivery windows span 15–30 days for off-the-shelf models, while customized units may require 35–45 days. Export-ready infrastructure supports global distribution, with most suppliers experienced in FOB and CIF shipping terms.

How to Choose String Hopper Machine Suppliers?

Procurement decisions should be guided by technical, operational, and transactional verification protocols:

Technical Specifications & Compliance

Confirm adherence to relevant standards such as ISO 9001 for quality management and CE marking where applicable for electrical components. For food-grade or sanitary applications, verify use of 304 or 316 stainless steel and compliance with hygiene design principles. Request documentation on motor efficiency, load capacity (e.g., 50kg–300kg), and integration compatibility with downstream machinery.

Production and Customization Capability

Assess supplier capacity through verifiable metrics:

- Minimum factory area exceeding 3,000m² for consistent batch production

- In-house engineering teams capable of customizing feed rate, voltage (110V/220V), size, and control systems

- Proven experience with OEM/ODM projects, including logo, labeling, and packaging modifications

Cross-reference customization claims with actual product listings and client testimonials to validate flexibility.

Supply Chain Reliability & Transaction Security

Prioritize suppliers with documented on-time delivery rates above 97% and response times under 3 hours. Analyze reorder rates as a proxy for customer satisfaction—values exceeding 30% indicate strong post-sale performance. Utilize secure payment mechanisms such as escrow services and insist on pre-shipment inspections for orders over $10,000. Sample testing is recommended to evaluate build quality, vibration stability, and feeding accuracy before full-scale procurement.

What Are the Best String Hopper Machine Suppliers?

| Company Name | Location | Main Products | Price Range (Units) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Taian Jiyi Machinery Equipment Co., Ltd. | Shandong, CN | Feed Processing Machines, Animal Husbandry Equipment | $350–$1,250 | 1 set | 100% | ≤2h | 29% | US $80,000+ |

| Dongguan Skyegle Intelligent Technology Co., Ltd. | Guangdong, CN | Sports Training Equipment, Badminton Stringing Machines | $1,828–$2,286 | 1 piece | 97% | ≤2h | <15% | US $380,000+ |

| Xiamen Seasoar Import & Export Co., Ltd. | Fujian, CN | Meat Tools, BBQ Grills, Home Brewing Kits | $66.40–$110 | 100–200 pieces | 100% | ≤3h | - | - |

| Dongguan Mingkai Electromechanical Co., Ltd. | Guangdong, CN | Plastic Hopper Dryers, Granule Handling Systems | $59–$180 | 1–2 sets | 98% | ≤2h | 20% | US $530,000+ |

| Suzhou Huibao Automation Equipment Co., Ltd. | Jiangsu, CN | Vibratory Feeders, Capping Machines, Industrial Automation | $500–$1,800 | 1 piece | 100% | ≤1h | 37% | US $30,000+ |

Performance Analysis

Dongguan Mingkai stands out for cost-effective solutions and high-volume readiness, offering entry-level hoppers from $59 with robust production infrastructure. Suzhou Huibao leads in after-sales loyalty, evidenced by a 37% reorder rate and sub-hour response times, making it ideal for buyers requiring responsive technical support. Taian Jiyi delivers reliability with 100% on-time fulfillment and mid-range pricing suited for agricultural and feed processing applications. Dongguan Skyegle targets niche markets with premium sports equipment, though its lower reorder rate suggests limited repeat demand in this segment. Xiamen Seasoar offers the lowest per-unit prices but requires higher MOQs, favoring bulk buyers focused on manual or small-scale models.

FAQs

How to verify string hopper machine supplier reliability?

Cross-check self-reported data with transaction history, customer reviews, and certification validity. Request facility videos or virtual audits to confirm production lines and quality control processes. Evaluate responsiveness, order fulfillment consistency, and communication clarity during initial inquiries.

What is the typical minimum order quantity (MOQ)?

MOQ varies by supplier and model: automated industrial units often require 1–2 sets, while consumer-grade or manual versions may mandate 100–200 pieces. Some suppliers offer single-unit sampling at elevated prices.

Do suppliers support customization?

Yes, many offer tailored solutions in material (stainless steel grade), voltage, capacity, and branding. Dongguan Mingkai and Suzhou Huibao explicitly list color, size, logo, and packaging customization options, supported by in-house design teams.

Are samples available before bulk ordering?

Most suppliers provide samples, typically priced at 1.5x–2x bulk rate. Lead time for sample production ranges from 7–15 days, with express shipping adding 5–10 business days internationally.

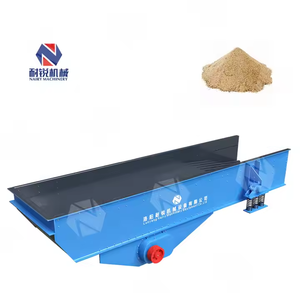

What are common applications of string hopper machines?

These machines are used across feed pellet production, plastic granule handling, food processing (e.g., meat stringing), and sports equipment manufacturing (e.g., racket stringing). Design variations reflect application-specific requirements for flow control, durability, and automation level.