Pallet Wrapper Machine Producer

About pallet wrapper machine producer

Where to Find Pallet Wrapper Machine Producers?

China remains the central hub for pallet wrapper machine production, with key manufacturing clusters in Shandong and Hebei provinces driving supply chain efficiency. Shandong hosts a concentrated network of packaging machinery specialists, particularly around Qingdao and Jinan, where integrated automation and material handling systems are developed alongside wrapping equipment. Hebei’s Xingtai region supports lean manufacturing operations focused on cost-effective semi-automatic and fully automatic turntable models.

These industrial zones benefit from mature supplier ecosystems, including servo motor distributors, film carriage component manufacturers, and structural steel fabricators operating within tight geographic proximity. This localization reduces component lead times by up to 40% compared to offshore alternatives. Facilities typically maintain vertical integration across CNC machining, robotic welding, and final assembly lines, enabling standard order fulfillment within 25–35 days. Buyers gain access to scalable production runs—from single-unit prototypes to container-scale batches—with pricing advantages averaging 20–30% over European or North American equivalents.

How to Choose Pallet Wrapper Machine Producers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international safety and performance benchmarks, including CE marking for electrical control panels and ISO 12100 compliance for mechanical risk assessment. For automated inline systems, verify PLC programming standards (Siemens or Allen-Bradley preferred) and compatibility with warehouse management systems (WMS). Request detailed CAD drawings and load simulation reports for custom configurations involving non-standard pallet sizes (e.g., EUR-pallets or heavy-duty industrial loads exceeding 2,000 kg).

Production Infrastructure Assessment

Evaluate core manufacturing capacity through objective metrics:

- Minimum factory footprint of 3,000m² to ensure dedicated assembly zones

- In-house fabrication capabilities for critical subsystems: turntables, mast assemblies, and pre-stretch film carriages

- Integration testing area for end-of-line functional validation

Cross-reference delivery performance (target ≥97%) with online revenue indicators and reorder rates as proxies for operational stability.

Procurement Risk Mitigation

Utilize secure payment frameworks such as escrow services that release funds only after shipment confirmation. Prioritize suppliers with documented quality control processes, including incoming material inspection, in-process gauging, and final calibration of tension control systems. Pre-shipment inspections—either via third-party agencies or remote video audits—are recommended for orders exceeding five units. Always request sample units to evaluate film pre-stretch ratios, cycle time consistency, and user interface responsiveness.

What Are the Leading Pallet Wrapper Machine Producers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Xingtai Zhipan Machinery Manufacturing Factory | Hebei, CN | Wrapping Machines (313) | 100% | ≤1h | 28% | US $10,000+ | $1,166–1,380 | 1 piece |

| Bremetz (Shandong) Machinery Co., Ltd. | Shandong, CN | Multi-Function Packaging Machines (244) | 100% | ≤3h | - | - | $800–26,000 | 1–50 sets |

| Zhengzhou Leabon Machinery Equipment Co., Ltd. | Henan, CN | Feed Processing Machines (457) | 100% | ≤5h | 100% | US $70,000+ | $5,980–29,980 | 1 set |

| Changshu Shu He Machinery Co., Ltd. | Jiangsu, CN | Packaging Line (238) | 100% | ≤6h | - | - | $1,800–35,000 | 1 set |

| Shandong Yizhou Science And Technology Development Co., Ltd. | Shandong, CN | Wrapping Machines (1052) | 97% | ≤2h | 31% | US $120,000+ | $1,000–2,200 | 1 set |

Performance Analysis

Xingtai Zhipan and Shandong Yizhou offer entry-level automation at competitive price points, with MOQs starting at one unit and rapid response times (<2 hours), making them suitable for small businesses or pilot deployments. Zhengzhou Leabon stands out with a 100% reorder rate and higher-value offerings, indicating strong customer satisfaction with its fully automatic and robotic-integrated systems. Bremetz and Changshu Shu He focus on engineered solutions, including inline and multi-axis wrapping cells, though limited reorder data suggests lower repeat engagement. All listed producers maintain perfect on-time delivery records except Shandong Yizhou (97%), reinforcing reliability across the cohort. Suppliers with verified online revenue exceeding US $70,000 demonstrate sustained export activity and likely have established QC protocols.

FAQs

What certifications should pallet wrapper machine producers have?

Essential certifications include CE for electrical safety and machine directives, especially for exports to Europe. ISO 9001 indicates formalized quality management systems. While not always present in supplier profiles, these credentials should be requested during due diligence.

What is the typical lead time for pallet wrapper machines?

Standard models are generally delivered within 20–30 days after order confirmation. Custom designs involving servo-driven rotary arms or integration with conveyor systems may require 45–60 days, depending on complexity and component availability.

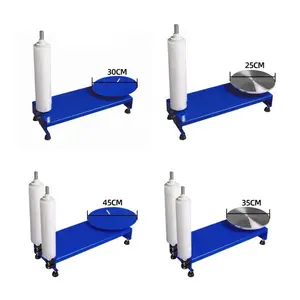

Can producers customize machine specifications?

Yes, most suppliers support customization of load capacity (up to 3,000 kg), turntable diameter (up to 2,500 mm), and film pre-stretch ratios (up to 300%). Control panel language, voltage (110V/220V/380V), and IoT-enabled monitoring can also be tailored upon request.

Do suppliers offer samples or trial units?

Sample policies vary. Some manufacturers provide demonstration videos or refurbished units for evaluation. New unit sampling is often available at 110–130% of standard pricing, with full credit applied upon subsequent bulk orders.

What are common packaging and shipping methods?

Machines are typically crated in seaworthy wooden enclosures with anti-corrosion coating and desiccant packs. FOB terms are standard; buyers arrange final freight. Air freight is viable for single units (lead time: 5–10 days), while sea shipping (20–35 days) is economical for container loads.