Paper Box Making Machine Price In India

Top sponsor listing

Top sponsor listing

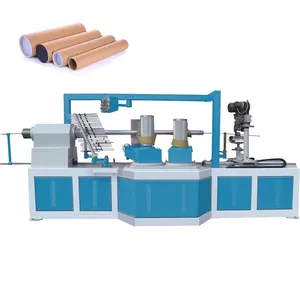

1/16

1/16

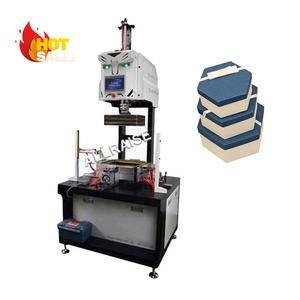

1/13

1/13

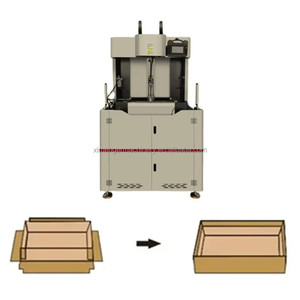

1/12

1/12

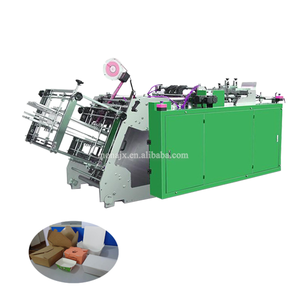

1/10

1/10

1/17

1/17

1/15

1/15

About paper box making machine price in india

Where to Find Paper Box Making Machine Suppliers?

China remains the dominant global manufacturing hub for paper box making machinery, with concentrated industrial clusters in Zhengzhou, Henan Province, serving as a primary sourcing region. This area hosts multiple specialized manufacturers offering a full spectrum of equipment—from semi-automatic to fully automated systems—designed for producing rigid boxes, food containers, gift packaging, and corrugated clamshells. The cluster benefits from vertically integrated supply chains, including access to steel fabrication, CNC machining, and electrical component suppliers within close proximity, enabling efficient production cycles and rapid parts replacement.

Manufacturers in this region operate scalable facilities equipped with modern assembly lines, supporting monthly outputs ranging from 20 to 100+ units depending on automation level and customization complexity. Key materials used in machine construction include high-tensile steel frames, aluminum alloy molds, and industrial-grade electrical control systems. Processing techniques such as laser cutting, precision welding, and surface coating ensure durability and consistent performance under continuous operation. With logistics infrastructure centered around Zhengzhou’s rail and freight networks, international shipment to India and other markets is streamlined, typically achieving lead times of 30–45 days for standard configurations.

How to Choose Paper Box Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate risk and ensure long-term operational efficiency:

Technical Capabilities and Compliance

Verify that suppliers adhere to recognized quality management standards such as ISO 9001. While not always explicitly stated, CE marking indicates compliance with European safety directives, which often correlates with higher engineering integrity. Request documentation on motor specifications (e.g., frequency converters, servo drives), mold design tolerances, and pressure systems (e.g., hot press units). Machines intended for food-grade packaging must support use of non-toxic, FDA-compliant materials in contact zones.

Production Capacity and Customization Scope

Assess supplier capability through key indicators:

- Facility size and in-house production lines (prioritize suppliers with end-to-end control over fabrication)

- Range of supported paper types (kraft, coated board, bagasse, sugarcane fiber)

- Customization options for box dimensions, die-cutting patterns, logo embossing, and color printing (flexo or transfer)

- Integration readiness with downstream packaging systems (labeling, stacking, shrink-wrapping)

Cross-reference available product listings with reorder rates and response times to gauge reliability and customer satisfaction.

Transaction Security and After-Sales Support

Opt for suppliers offering verifiable transaction protection mechanisms. Evaluate after-sales service depth, including availability of technical manuals, remote troubleshooting, and spare parts supply. Confirm whether installation guidance or on-site commissioning support is provided, particularly critical for automated models requiring precise calibration.

What Are the Best Paper Box Making Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Perfect Co., Ltd. | Paper Product Making Machinery, Flexographic Printers, Thermoforming Machines | Not specified | 1 set | 100% | ≤3h | <15% | $50K+ | Yes |

| Ruian Daqiao Packaging Machinery Co., Ltd. | Paper Processing Machinery, Foil Container Equipment | $7,500–$30,000 | 1 set | 100% | ≤3h | <15% | $40K+ | Limited |

| ZHENGZHOU ALLRAISE COMPANY LTD. | Automatic Cardboard Forming, Rigid Box Machines | $7,500–$12,571 | 1 set | 98% | ≤3h | 39% | $950K+ | Yes |

| Zhengzhou Enson Industrial Co., Ltd. | Paper Punnet Trays, Clamshell Makers, Laminating Systems | $7,000–$18,460 | 1 set | 100% | ≤1h | 100% | $10K+ | Yes |

| Zhengzhou Ximenger Machinery Co., Ltd. | Semi-Automatic & Manual Rigid Box Formers | $700–$9,500 | 1 set | 100% | ≤2h | 38% | $90K+ | Yes |

Performance Analysis

Suppliers like Zhengzhou Enson Industrial demonstrate exceptional responsiveness (≤1h average reply time) and perfect reorder rates, indicating strong post-sale satisfaction despite lower reported revenue volume. ZHENGZHOU ALLRAISE COMPANY LTD. stands out with high online transaction volume ($950K+) and a 39% reorder rate, suggesting consistent product quality and market acceptance. Ruian Daqiao offers one of the widest price ranges, catering to both entry-level and high-capacity buyers, while maintaining 100% on-time delivery. Notably, all top-tier suppliers offer customization in box size, material compatibility, and branding integration, with several supporting advanced features such as frequency converter controls and automated stacking. For Indian importers, prioritizing suppliers with proven export experience, clear pricing structures, and fast communication channels minimizes procurement friction.

FAQs

What is the typical price range for paper box making machines in India?

Imported machine prices range from $700 for manual models to over $30,000 for fully automated, high-speed production lines. Most mid-range automatic systems fall between $7,500 and $18,500, depending on output capacity, degree of automation, and included tooling.

What are common MOQ and lead time expectations?

Minimum order quantity is typically 1 set, accommodating small-scale processors and startups. Standard lead times range from 20 to 40 days after deposit confirmation, with sea freight adding 25–35 days for Indian ports.

Can suppliers customize machines for specific box designs?

Yes, most suppliers listed offer customization for box dimensions, mold shape, corner sealing method, and surface decoration (embossing, foil stamping, flexo printing). Digital design submission is required for mold development, with prototype testing recommended before mass production.

Do these machines support eco-friendly materials?

Yes, many models are compatible with sustainable substrates such as bagasse, molded pulp, and recycled cardboard. Confirm material thickness range (typically 150–600gsm) and heat resistance requirements with the supplier prior to purchase.

How can buyers verify machine quality before ordering?

Request factory audit reports, third-party inspection records, or video walkthroughs of operational units. Sample production runs—either virtual via video or physical samples shipped at buyer’s cost—are effective validation tools. Ensure test runs include full cycle operations under load to assess stability and consistency.