Paper Box Making Machine Producer

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/16

1/16

1/3

1/3

1/3

1/3

1/16

1/16

0

0

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/9

1/9

1/3

1/3

1/1

1/1

1/10

1/10

1/3

1/3

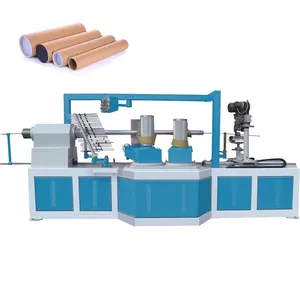

About paper box making machine producer

Where to Find Paper Box Making Machine Producers?

China remains the global epicenter for paper box making machine manufacturing, with key industrial hubs concentrated in Zhejiang, Guangdong, and Henan provinces. These regions host vertically integrated supply chains combining precision engineering, sheet metal fabrication, and automation expertise. Wenzhou and Ruian in Zhejiang specialize in high-speed packaging machinery, supported by localized component suppliers reducing lead times by 25–30%. Dongguan in Guangdong focuses on advanced bag and handle production systems, leveraging proximity to electronics and control module manufacturers. Zhengzhou in Henan has emerged as a center for cost-competitive rigid box forming equipment, serving both domestic and export markets.

The clustering effect enables efficient access to CNC machining, laser cutting, and robotic assembly capabilities within a 50km radius. This integration supports rapid prototyping and scalable production, with standard lead times averaging 30–45 days. Buyers benefit from competitive pricing—driven by localized material sourcing—and flexibility in customization, including size, material compatibility, and automation levels. Export readiness is widespread, with most suppliers experienced in international logistics and compliance documentation.

How to Choose Paper Box Making Machine Producers?

Selecting reliable producers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

Verify compatibility with target materials such as kraft paper, corrugated board, or food-grade paperboard. Assess machine specifications for adjustable parameters: paper width (typically 100–800mm), folding precision (±0.5mm), and output speed (ranging from 30 to 200 boxes/minute). For food packaging applications, confirm adherence to hygienic design standards and compatibility with water-based or cold glue systems.

Production Capacity & Infrastructure

Evaluate supplier scale through key indicators:

- Minimum factory area of 3,000m² for stable batch production

- In-house R&D teams capable of custom mold and PLC programming

- On-site testing facilities for dry-run demonstrations

Cross-reference online revenue data and product listing volume as proxies for market presence and order fulfillment capacity.

Quality Assurance & Transaction Security

Prioritize suppliers with documented quality management practices. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and reorder rates exceeding 20% indicate operational reliability. Use secure payment mechanisms and request pre-shipment inspections. Sample validation is critical—test machine performance under real production conditions before full-scale ordering.

What Are the Leading Paper Box Making Machine Producers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Chuangfeng Machinery Co., Ltd. | Paper Product Making Machinery (256) | $740,000+ | 100% | 40% | ≤2h | kraft paper, color, thickness, logo, moulds | N/A | 1 set |

| Dongguan Feiyang Packaging Machinery Equipment Co., Ltd. | Bag Making Machines (246) | $20,000+ | 95% | 20% | ≤1h | material, size, handle type | $16,000–$52,000 | 1 set |

| AOPACK Ltd. | Other Packaging Machines (147) | $40,000+ | 100% | - | ≤2h | carton design, on-demand production | $50,000–$150,000 | 1 piece |

| ZHENGZHOU ALLRAISE COMPANY LTD. | Paper Product Making Machinery (N/A) | $980,000+ | 96% | 40% | ≤3h | color, material, size, logo, packaging | $6,500–$12,600 | 1 set |

| Ruian Xiaohai Machinery Factory | Bag Making Machines (119) | $1,000+ | 100% | <15% | ≤3h | size, material, automation level | $8,000–$18,000 | 1 set |

Performance Analysis

Wenzhou Chuangfeng and Zhengzhou Allraise demonstrate strong customer retention (40% reorder rate), indicating satisfaction with machine reliability and after-sales support. AOPACK and Ruian Xiaohai achieve perfect on-time delivery records, suggesting disciplined production planning despite limited public reorder metrics. Price stratification is evident: entry-level semi-automatic systems start around $6,500, while fully automated, high-capacity lines exceed $100,000. Suppliers like Feiyang and AOPACK focus on premium segments with complex carton and handle integration, whereas Allraise and Xiaohai offer economical solutions for small to mid-sized operations. Response times across the segment are generally fast, with 80% of suppliers replying within three hours.

FAQs

How to verify paper box making machine producer reliability?

Assess consistency in on-time delivery (target ≥95%) and reorder rate (ideally >20%). Request video tours of production facilities to verify operational scale. Confirm technical support availability for installation and troubleshooting. Review product listings for detailed specifications, CE markings, and application-specific configurations.

What is the typical MOQ and lead time?

Standard minimum order quantity is one set, with lead times ranging from 20 to 45 days depending on automation level and customization. Simple semi-automatic models ship faster, while turnkey production lines may require additional commissioning time.

Can these machines handle food-safe packaging?

Yes, select models are designed for food-grade paperboard processing using non-toxic adhesives and stainless steel contact parts. Buyers must specify hygiene requirements upfront to ensure compliance with local food safety regulations.

Do suppliers offer customization?

Extensive customization is available, including box dimensions, folding patterns, printing integration, and automation interfaces. Mold development for unique box shapes is commonly offered, with lead times of 7–14 days for tooling fabrication.

What are the common payment and shipping terms?

Payment terms typically include T/T (30% deposit, 70% before shipment) or platform-based escrow. Shipping is usually FOB from Chinese ports, with sea freight recommended for heavy machinery to minimize costs. Air freight is viable only for spare parts or urgent samples.