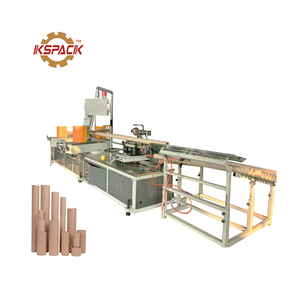

Paper Core Machine

Top sponsor listing

Top sponsor listing

1/6

1/6

CN

CN

1/17

1/17

1/21

1/21

1/16

1/16

1/13

1/13

1/14

1/14

1/14

1/14

1/14

1/14

1/16

1/16

About paper core machine

Where to Find Paper Core Machine Suppliers?

China remains the global epicenter for paper core machine manufacturing, with key production clusters concentrated in Zhejiang, Hebei, and Shandong provinces. Wenzhou in Zhejiang Province hosts a dense network of specialized machinery firms focusing on precision paper processing equipment, benefiting from mature supply chains for kraft paper, adhesives, and CNC components. Xingtai in Hebei has emerged as a cost-competitive hub for semi-automatic and manual models, where lower labor and operational costs reduce unit prices by 10–15% compared to coastal counterparts.

These industrial zones support vertically integrated operations—from sheet metal fabrication to final assembly—enabling rapid prototyping and scalable production. Suppliers typically operate within ecosystems where raw material vendors, mold manufacturers, and logistics providers are located within 30–50km, reducing component lead times by up to 40%. Buyers benefit from average production lead times of 20–35 days for standard configurations, with customization options widely available across diameter ranges (15–300mm), material thickness (0.2–1.5mm), and output speeds (up to 18,000 cores/hour).

How to Choose Paper Core Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Assess suppliers based on their engineering scope and process control. Prioritize manufacturers offering full automation (CNC-controlled winding, laser-guided cutting) over manual or semi-automatic systems for high-volume applications. Verify access to in-house tooling design for custom molds, which reduces setup time for non-standard diameters or conical cores. Look for integration of variable frequency drives (VFDs) and touch-screen HMI interfaces as indicators of modern control systems.

Quality Assurance Protocols

While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates (≥97%) and verifiable response times (≤2 hours) serve as proxy indicators of internal quality management. Confirm that machines undergo load testing with real-world materials (kraft paper, adhesive tapes) before shipment. For export compliance, CE marking is increasingly common among established exporters, particularly for fully automatic lines destined for EU and North American markets.

Customization and After-Sales Support

Leading suppliers offer modular designs adaptable to diverse substrates—kraft paper, label stock, or laminated composites—with adjustable parameters for glue application, tension control, and core length. Evaluate customization depth: top-tier suppliers support changes in inner diameter, wall thickness, printing integration, and labeling systems. Post-delivery support, including remote diagnostics, spare parts availability, and operator training, should be contractually defined prior to order placement.

What Are the Best Paper Core Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Key Customization Options |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Chuangfeng Machinery Co., Ltd. | Zhejiang, CN | Custom Manufacturer | $660,000+ | 100% | ≤2h | 36% | Paper Tube, Straw, Bobbin Machines | Diameter, length, color, logo, paper type |

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | $1,300,000+ | 100% | ≤1h | <15% | Manual to Fully Automatic Tube Makers | Material, size, packaging, graphic design |

| Xingtai Mintai Machinery Manufacturing Co., Ltd. | Hebei, CN | - | $20,000+ | 100% | ≤5h | <15% | Cutters, Auto Core Makers | Multi-knife cutters, size-specific molds |

| Qingdao YiDaFa International Trade Co., Ltd. | Shandong, CN | Multispecialty Supplier | Not disclosed | 100% | ≤2h | <15% | High-Speed Jumbo & CNC Models | Diameter, material, capacity, waste handling |

| Suzhou Superman Trading Co., Ltd. | Jiangsu, CN | - | $70,000+ | 100% | ≤3h | <15% | Semi-Auto to Full Auto Cutters | Cardboard, kraft, multi-knife setups |

Performance Analysis

Wenzhou-based suppliers dominate responsiveness and customization breadth, with Roman Machinery leading in online transaction volume ($1.3M+) and sub-one-hour response times. Chuangfeng stands out with a 36% reorder rate—the highest among peers—indicating strong customer retention likely driven by dedicated OEM services. While most suppliers report 100% on-time delivery, revenue disparities suggest differences in export maturity and after-sales infrastructure. Buyers seeking high-speed, large-format (e.g., 1600mm jumbo roll) machines should prioritize Qingdao YiDaFa and Wenzhou Roman, which list advanced CNC and full-auto models priced above $10,000. For budget-conscious buyers, Xingtai Mintai offers entry-level cutters starting at $500/unit with reliable performance metrics.

FAQs

What is the typical MOQ and pricing range for paper core machines?

Minimum Order Quantity is generally 1 set across all suppliers, facilitating sample procurement and small-scale deployment. Pricing varies significantly by automation level: manual cutters start at $500–$800/set, semi-automatic models range from $3,000–$4,500/set, while fully automatic production lines reach $13,000–$20,000/set depending on speed and integration features.

How long does it take to fulfill an order?

Standard orders are fulfilled within 20–30 days after deposit confirmation. Customized machines requiring new molds or control system adjustments may extend lead times to 35–45 days. Air freight delivery adds 5–7 days internationally; sea freight takes 25–35 days depending on destination port.

Can suppliers provide machine validation samples?

Yes, most suppliers offer test-produced paper cores using customer-specified parameters (diameter, length, paper grade). Some charge nominal fees for sample production and shipping, while others waive costs for confirmed bulk orders. Physical samples allow verification of edge smoothness, concentricity, and adhesive bonding quality.

Do suppliers support OEM/ODM configurations?

Leading manufacturers like Wenzhou Chuangfeng and Roman Machinery explicitly offer OEM branding, including customized logos, color schemes, and user interface labels. ODM services include tailored gearbox ratios, motor power ratings, and integration with downstream packaging systems.

What payment and transaction security options are available?

Common terms include 30% T/T deposit with balance before shipment. Some suppliers support trade assurance programs that escrow payments until inspection clearance. For first-time transactions, third-party inspection agencies (e.g., SGS, BV) can be contracted to audit factory output and verify machine performance against agreed specifications.