Pbc Linear Hevi Rail

1/25

1/25

1/18

1/18

1/20

1/20

1/27

1/27

1/25

1/25

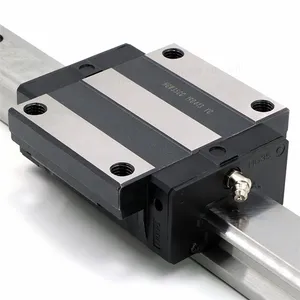

About pbc linear hevi rail

Where to Find PBC Linear Heavy Rail Suppliers?

China remains the global hub for precision linear motion components, with key manufacturing clusters in Shenzhen, Chengdu, and Tianjin offering specialized expertise in heavy-duty rail systems. Shenzhen and Chengdu are home to advanced CNC machining centers and automation-focused engineering firms that produce high-precision PBC linear heavy rails used in industrial automation, CNC machinery, and material handling systems. These regions benefit from tightly integrated supply chains for stainless steel, aluminum alloys, and hardened bearing materials, reducing component lead times by 20–35% compared to offshore alternatives.

The industrial ecosystems in these cities support vertically integrated production—from raw material processing to final assembly—enabling suppliers to maintain tight tolerances (±0.01mm) and deliver both standard and custom rail configurations efficiently. Buyers gain access to agile manufacturers capable of fulfilling low-volume OEM orders or scaling to bulk shipments, supported by responsive logistics networks. Typical advantages include 25–40% lower unit costs due to localized sourcing, average lead times of 15–30 days for stocked items, and strong capabilities in customization including length trimming, drilling patterns, surface treatments, and load-specific design adjustments.

How to Choose PBC Linear Heavy Rail Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical capability, operational performance, and transactional transparency.

Technical & Quality Assurance

Confirm adherence to international quality standards such as ISO 9001. While formal certification is not always listed, consistent on-time delivery rates above 95% and documented product testing indicate robust internal quality management. For applications requiring corrosion resistance or high load capacity (up to 102kg per set), verify material specifications—common options include hardened carbon steel, stainless steel, and anodized aluminum—and demand dimensional drawings or CAD files before order placement.

Production Capacity and Responsiveness

Assess supplier scalability through available indicators:

- Response time under 2 hours signals strong customer service infrastructure

- Reorder rates exceeding 25% reflect customer satisfaction and product reliability

- Online revenue above US $70,000 suggests established market presence and order volume

Suppliers with customization capabilities often list options for labeling, packaging, multi-axis integration, and motor control compatibility, indicating engineering flexibility for complex automation setups.

Procurement Safeguards

Utilize secure payment methods where possible, especially for first-time transactions. Request sample units to validate dimensional accuracy, surface finish, and smoothness of motion prior to full procurement. Cross-check product listings with declared minimum order quantities (MOQs), which range from 1 piece/set to bulk tonnage-based orders, ensuring alignment with project requirements.

What Are the Best PBC Linear Heavy Rail Suppliers?

| Company Name | Location | Main Products | Customization | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Phoenix Technology Company Limited | Hong Kong, CN | Linear Guides, Testing Equipment, Wood Routers | Limited | 100% | ≤2h | 25% | US $130,000+ | - |

| Shenzhen Perfect Precision Products Co., Ltd. | Shenzhen, CN | Linear Guides | Limited | 100% | ≤1h | 40% | US $6,000+ | - |

| Chengdu Lian Dong Rui Xin Technology Co., Ltd. | Chengdu, CN | Linear Guide Blocks, Motor Control Systems | Yes | 100% | ≤1h | <15% | US $130,000+ | Custom Manufacturer |

| Asia FON (Tianjin) Technology Co., Ltd. | Tianjin, CN | Ball Screws, Linear Guides, Seals | Limited | 95% | ≤5h | <15% | US $30,000+ | - |

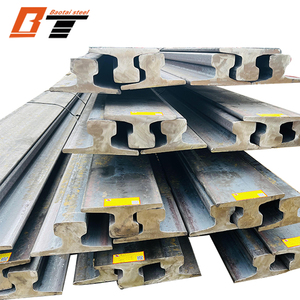

| Shandong Baotai Steel Co., Ltd. | Shandong, CN | Steel Rails, Crane Components | Yes | 100% | ≤3h | - | US $70,000+ | Multispecialty Supplier |

Performance Analysis

Shenzhen Perfect Precision stands out with a 40% reorder rate and sub-1-hour response time, indicating high buyer retention and operational efficiency. Chengdu Lian Dong Rui Xin and Shandong Baotai offer full customization, making them suitable for engineered-to-order applications in automation and structural systems. Phoenix Technology and Shandong Baotai report revenues exceeding US $130,000 and US $70,000 respectively, reflecting significant market engagement. While Asia FON has a slightly lower on-time delivery rate (95%), its focus on core motion components like ball screws and seals supports integration into larger mechanical assemblies. Prioritize suppliers with 100% on-time delivery and response times under 2 hours for mission-critical procurement timelines.

FAQs

What materials are commonly used in PBC linear heavy rails?

Standard materials include hardened carbon steel, stainless steel, and anodized aluminum alloy. Stainless variants are preferred for corrosive environments, while carbon steel offers higher load-bearing capacity at lower cost.

What is the typical MOQ for PBC linear heavy rails?

Minimum order quantities vary: some suppliers offer single-piece purchases (e.g., 1 piece or 1 set), while others require bulk orders starting at 2 pieces or up to 10 tons for raw rail stock, depending on manufacturing model and material form.

Can I request custom lengths or mounting configurations?

Yes, several suppliers—particularly Chengdu Lian Dong Rui Xin and Shandong Baotai—support customization in length, drilling patterns, labeling, and surface treatment. Technical drawings or specifications should be provided upfront for accurate quoting.

What are the price ranges for PBC linear heavy rails?

Prices range from $1.50 per piece for basic SBR-type rails to over $1,400 for high-load, precision-engineered sets. Cost depends on material, load rating, length, and whether the order includes carriages or complete guide systems.

How long does it take to receive samples or bulk orders?

Sample lead times typically range from 7 to 15 days. Bulk production lead times average 15–30 days, depending on order complexity and customization level. Shipping via express courier takes 3–7 days internationally; sea freight may require 25–40 days for full container loads.