Pcb Assembly And Printing

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About pcb assembly and printing

Where to Find PCB Assembly and Printing Suppliers?

China remains the global epicenter for printed circuit board (PCB) manufacturing, with Shenzhen and Guangdong province serving as primary hubs due to concentrated electronics supply chains and specialized industrial zones. These regions host vertically integrated facilities capable of handling prototyping, high-volume production, and full turnkey assembly services. Proximity to component distributors, SMT line suppliers, and testing laboratories enables rapid iteration and reduced logistics overhead.

The ecosystem supports agile production cycles, with many suppliers offering 24–72 hour turnaround for sample batches and 5–10 day lead times for small-volume orders. Localized access to FR-4, aluminum substrates, and high-frequency materials (e.g., Rogers) ensures cost-efficient material sourcing. Buyers benefit from scalable output—ranging from one-off prototypes to monthly volumes exceeding 50,000 units—while maintaining compliance with international standards such as IPC-A-610 and RoHS.

How to Choose PCB Assembly and Printing Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to recognized quality management systems, including ISO 9001 certification. For export markets, ensure compliance with IPC Class 2/3 standards for soldering and board integrity. Request documentation on solder paste inspection (SPI), automated optical inspection (AOI), and in-circuit testing (ICT) protocols. Environmental compliance (RoHS, REACH) is mandatory for consumer electronics and industrial equipment destined for EU or North American markets.

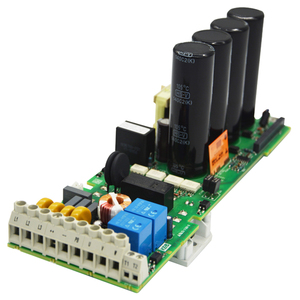

Production Capabilities Assessment

Evaluate key operational metrics:

- Minimum capability of 1–8 layer PCB fabrication; advanced suppliers support up to 32 layers

- In-house SMT lines with pick-and-place machines operating at ≥50,000 CPH (components per hour)

- Availability of through-hole, BGA rework, and conformal coating processes

Confirm multilayer lamination control, impedance matching, and controlled depth routing if required. Cross-reference supplier claims with on-time delivery performance (target: ≥98%) and response time benchmarks.

Procurement Risk Mitigation

Utilize secure payment mechanisms where funds are released post-inspection. Prioritize suppliers with verifiable order histories and transparent communication patterns. Conduct pre-shipment inspections or request X-ray reports for BGA assemblies. Prototype validation should include functional testing under real-world conditions before scaling to mass production.

What Are the Best PCB Assembly and Printing Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ | Price Range (USD) | Verified Status |

|---|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | PCBA, Multilayer PCB, Other PCB & PCBA | US $1,000+ | 100% | 66% | ≤1h | 1 piece | $1.10–1.20 | Multispecialty Supplier |

| Shenzhen Seeme Technology Co., Ltd. | PCBA, Smart GPS Tracker, Bluetooth Earbud Board | US $10,000+ | 100% | 33% | ≤6h | 2 pieces | $0.50–3.00 | - |

| Shenzhen Pinkuo Trading Co., Ltd. | OEM PCB/PCBA, Vending Machine Control Boards | US $20,000+ | 100% | <15% | ≤1h | 5–1,000 pieces | $0.09–10.00 | - |

| Hongtai Technology Co Ltd | PCBA, FPC, Metal Core PCB | US $3,000+ | 100% | <15% | ≤5h | 1 piece | $1.00–20.00 | - |

Performance Analysis

Toptek Pcb Co., Limited demonstrates strong buyer retention (66% reorder rate) and immediate responsiveness (≤1h), making it a preferred partner for iterative development and low-MOQ trials. Shenzhen Seeme Technology targets niche applications like Bluetooth wearables and GPS trackers, supported by higher annual revenue ($10,000+) and competitive pricing starting at $0.50/unit. Shenzhen Pinkuo stands out in volume capacity, accepting MOQs up to 1,000 pieces with flexible pricing tiers, ideal for mid-to-high volume deployments. Hongtai Technology offers broad material versatility, including metal-core and flexible PCBs, though its lower reorder rate suggests room for improvement in long-term client engagement. All listed suppliers maintain perfect on-time delivery records, indicating reliable logistical execution.

FAQs

How to verify PCB assembly supplier reliability?

Request copies of quality certifications (ISO 9001, IPC membership), factory audit reports, and customer references. Validate process controls through video tours of SMT lines and inspection stations. Analyze transaction history for consistency in delivery and communication responsiveness.

What is the typical sampling timeline for custom PCBs?

Standard prototype lead times range from 3–7 days for bare boards and 5–10 days for assembled units. Complex multilayer or impedance-controlled designs may require 10–15 days. Add 3–7 days for international express shipping.

Can suppliers handle full turnkey PCB assembly?

Yes, multiple suppliers in this dataset offer complete turnkey services—including component sourcing, BOM validation, assembly, and final testing. Confirm availability of parts procurement support and counterfeit component mitigation policies prior to order placement.

Do PCB manufacturers provide free samples?

Sample fee waivers are uncommon but negotiable for future volume commitments. Most suppliers charge a nominal setup fee covering stencil and programming costs, which may be credited toward subsequent production runs.

How to initiate customization requests?

Submit Gerber files, BOM, and assembly drawings via secure channels. Specify requirements for solder mask color, silkscreen, panelization, and testing (e.g., flying probe, fixture-based). Reputable suppliers will return DFM feedback within 24 hours and begin production upon approval.