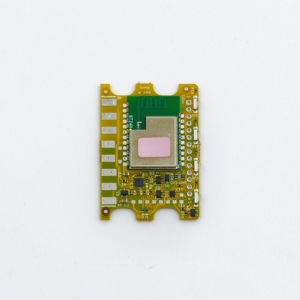

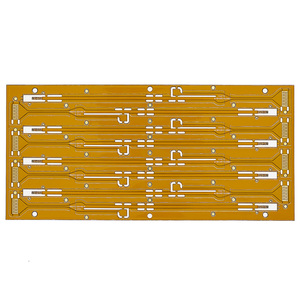

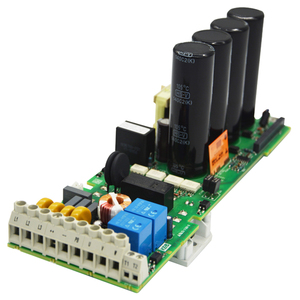

Pcb Assembly Steps

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

1/20

1/20

1/31

1/31

1/34

1/34

1/26

1/26

1/61

1/61

1/25

1/25

1/24

1/24

CN

CN

CN

CN

1/18

1/18

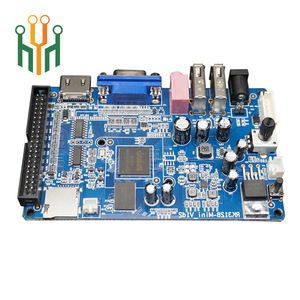

About pcb assembly steps

Where to Find PCB Assembly Services Suppliers?

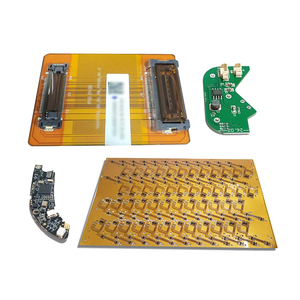

China remains the global epicenter for printed circuit board (PCB) assembly services, with Shenzhen at the core of a highly specialized electronics manufacturing ecosystem. This region hosts a dense network of vertically integrated suppliers offering end-to-end solutions—from bare PCB fabrication to full turnkey PCBA production. The concentration of component distributors, SMT line operators, and testing facilities within 50km enables rapid prototyping and scalable batch production.

Suppliers in this cluster benefit from mature supply chains that reduce material procurement lead times by 30–40% compared to non-specialized regions. Buyers gain access to advanced surface mount technology (SMT), through-hole (DIP), and mixed-technology assembly lines capable of handling single-layer to multilayer boards. Typical turnaround times range from 3–7 days for prototypes and 10–15 days for volume orders, depending on complexity. Cost efficiencies are further enhanced by localized sourcing of FR-4, aluminum substrates, and HDI materials, enabling competitive pricing across low, medium, and high-volume runs.

How to Choose PCB Assembly Services Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Management Standards

Verify adherence to IPC-A-610 Class 2 or Class 3 standards for electronic assemblies. While not all suppliers list ISO 9001 certification explicitly, consistent on-time delivery performance (>97%) and compliance with RoHS/REACH directives indicate robust quality systems. For medical, automotive, or aerospace applications, demand documented process controls and traceability protocols.

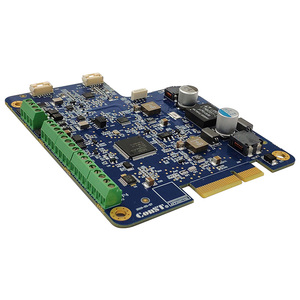

Production Capability Assessment

Evaluate key infrastructure indicators:

- Availability of automated SMT lines with placement accuracy down to 0.1mm pitch

- In-house capabilities for multilayer PCB lamination, impedance control, and via filling

- Testing resources including AOI, X-ray inspection, and functional test fixtures

Cross-reference service descriptions with product listings showing actual unit prices and minimum order quantities (MOQs) as proxies for scalability.

Procurement Risk Mitigation

Prioritize suppliers with verifiable response times ≤2 hours and 100% on-time delivery records. Analyze reorder rates as an indicator of customer satisfaction—rates exceeding 40% suggest consistent quality and service reliability. Implement incremental ordering strategies starting with prototype batches before scaling. Confirm support for reverse engineering, BOM optimization, and design-for-manufacturability (DFM) reviews to minimize downstream revisions.

What Are the Best PCB Assembly Services Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verification Status | Sample MOQ | Unit Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Multilayer PCB, PCBA, Other PCB & PCBA | 100.0% | ≤1h | 66% | US $1,000+ | Multispecialty Supplier | 1 piece | $0.90–1.20 |

| Shenzhen Xuyuxin Technology Co., Ltd. | PCBA, Other PCB & PCBA | 100.0% | ≤1h | - | - | - | 1 piece | $0.45–5.99 |

| Shenzhen Huayihai Technology Co., Ltd. | PCBA, Switches, Other PCB & PCBA | 100.0% | ≤2h | <15% | US $1,000+ | - | 1 piece | $0.10–4.50 |

| Shenzhen Wanfeng Technology Co., Ltd. | Customization options: color, material, size, logo, packaging, label, graphic | 100.0% | ≤1h | 40% | US $550,000+ | Custom Manufacturer | 1 piece | $0.50–8.00 |

Performance Analysis

Toptek Pcb Co., Limited stands out with a 66% reorder rate and consistent sub-hour response time, indicating strong customer retention and operational responsiveness. Shenzhen Wanfeng Technology demonstrates significant scale, supported by high online revenue and a broad customization portfolio spanning material selection and branding elements. Despite limited reorder data, Shenzhen Xuyuxin offers competitive entry-level pricing from $0.45 per unit, making it suitable for cost-sensitive prototype development. All listed suppliers maintain 100% on-time delivery performance, a critical benchmark for supply chain reliability. Buyers seeking high-mix, low-volume production should prioritize companies offering DFM feedback and component sourcing assistance visible in their service descriptions.

FAQs

What certifications should PCB assembly suppliers have?

While formal ISO 9001 or IATF 16949 certifications may not always be listed, look for evidence of standardized work instructions, inspection checklists, and environmental compliance (RoHS, REACH). IPC-A-610 acceptance criteria should govern final assembly evaluations.

What is the typical lead time for PCB assembly?

Prototype assemblies generally ship within 5–7 business days. Batch production for 100+ units takes 10–15 days, depending on stencil creation, component availability, and testing requirements. Rush services may reduce timelines by 3–5 days at a premium.

Do PCB assembly suppliers support small MOQs?

Yes, most suppliers accommodate MOQs as low as 1 piece, particularly for prototype or NPI (new product introduction) stages. Unit costs decrease significantly at volumes above 100–500 pieces due to fixed setup cost amortization.

Can suppliers source components for PCBA?

Reputable providers offer full BOM fulfillment, including active components, passives, and connectors. Confirm whether they use franchised distributors or open-market channels, as this impacts counterfeit risk and long-term supply continuity.

How are quality issues resolved post-delivery?

Established suppliers typically accept returns or rework defective boards if failure is attributable to assembly error. Define defect thresholds using AQL sampling standards (e.g., MIL-STD-105E) and request test reports (ICT, flying probe, or functional) with each shipment.