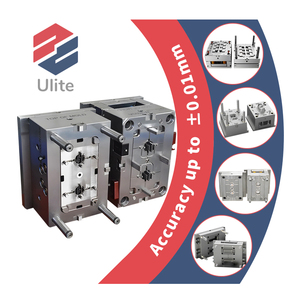

Precision Moulded Components

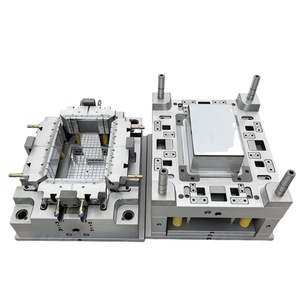

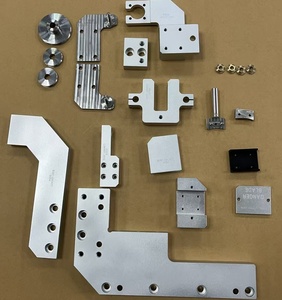

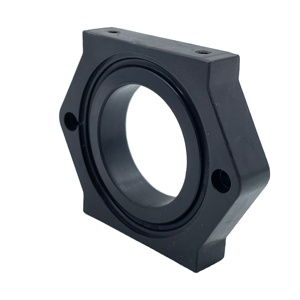

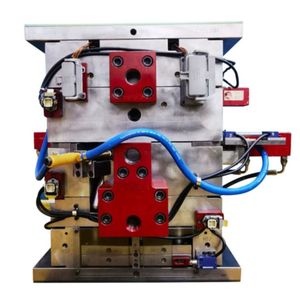

About precision moulded components

Where to Find Precision Moulded Components Suppliers?

China remains the global hub for precision moulded components manufacturing, with concentrated supplier clusters in Guangdong Province—particularly Shenzhen and Dongguan—driving innovation and scale. These regions host vertically integrated facilities specializing in injection molding, CNC machining, and die-casting, supported by mature supply chains for engineering plastics, metal alloys, and mold tooling. Proximity to ports like Shenzhen Yantian enables efficient export logistics, reducing transit times for international buyers.

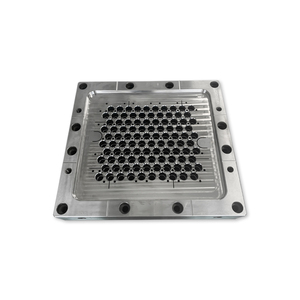

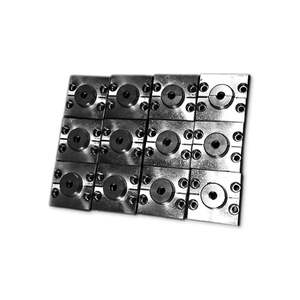

The ecosystem supports both high-volume production and low-MOQ custom orders, with many suppliers operating automated molding lines capable of monthly outputs exceeding 500,000 units. Advanced processing techniques—including multi-cavity molds, insert molding, and overmolding—are standard among leading manufacturers. Material expertise spans ABS, PA, PEEK, PC, and POM resins, as well as non-ferrous metals, enabling component fabrication for automotive, telecommunications, and industrial equipment sectors.

How to Choose Precision Moulded Components Suppliers?

Evaluate potential partners using the following criteria to ensure technical and operational alignment:

Quality Management Systems

Prioritize suppliers with ISO 9001 certification, which validates standardized quality control processes. While not all suppliers list CE or RoHS compliance explicitly, these should be confirmed for end-use applications in regulated markets. Review available test reports for material composition, dimensional accuracy, and part consistency.

Production and Engineering Capabilities

Assess infrastructure through verifiable metrics:

- In-house mold design and fabrication capabilities

- CNC, EDM, and wire-cutting machinery for precision tooling

- Injection molding machines ranging from 50T to 1,000T clamping force

- Dedicated teams for 2D/3D drawing interpretation and DFM analysis

Cross-reference online revenue indicators and reorder rates as proxies for reliability and customer satisfaction.

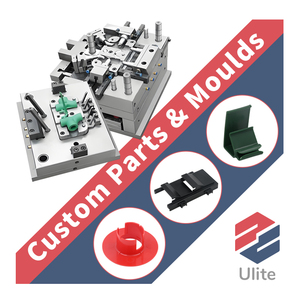

Customization and Transaction Security

Confirm scope of customization: color, material grade, surface finish (painting, plating, texture), labeling, and packaging. Leading suppliers support full OEM/ODM services, including logo integration and assembly. Utilize secure transaction methods such as escrow payments and request sample validation before mass production. Average response times under 4 hours indicate strong service commitment.

What Are the Best Precision Moulded Components Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Shunheng Precision Mould Co., Ltd. | Shenzhen, CN | US $90,000+ | Molded engineering parts, auto components | 100% | ≤4h | <15% | Material, size, color, 2D/3D drawings, logo, weight | 1 piece |

| Torch Mold Limited | Dongguan, CN | US $150,000+ | Plastic injection parts, radiator connectors | 97% | ≤2h | 29% | Resin type, painting, assembly, graphic design | 1 unit/piece |

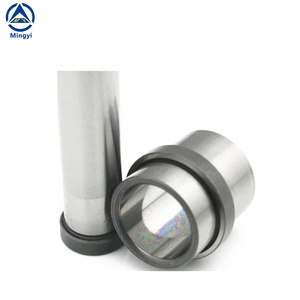

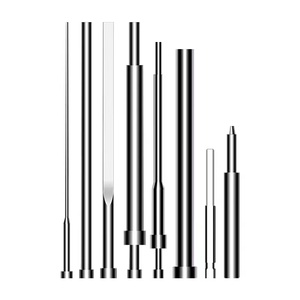

| Dongguan Mingyi Mold Co., Ltd. | Dongguan, CN | US $10,000+ | Mold pins, bushings, guide posts, non-standard parts | 100% | ≤3h | 20% | Limited (product-specific) | 1 piece |

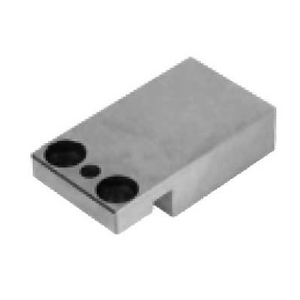

| Dongguan Tuoyu Precision Hardware Co., Ltd. | Dongguan, CN | US $80,000+ | Stamping dies, punch inserts, CNC-machined parts | 100% | ≤2h | 45% | Size, material, drawings, logo | 1 piece |

| Dongguan Baitong Precision Mould Manufacturing Co., Ltd. | Dongguan, CN | US $30,000+ | Standard mold components, CNC-machined spares | 96% | ≤5h | 31% | Material, thickness, working area, packaging | 1–10 pieces |

Performance Analysis

Torch Mold Limited leads in transaction volume and responsiveness, with a 97% on-time delivery rate and sub-2-hour average response time, making it suitable for urgent procurement cycles. Shenzhen Shunheng and Dongguan Tuoyu achieve perfect on-time delivery records, with Tuoyu standing out for its high 45% reorder rate—indicative of strong buyer retention. While Dongguan Mingyi lists a lower online revenue, its specialization in precision mold hardware (e.g., ejector pins, bushings) offers niche value for tooling maintenance. Most suppliers accommodate single-piece MOQs, facilitating prototyping and small-batch trials. Pricing typically ranges from $0.30 to $1.70 per unit for plastic molded components, with higher costs for engineered resins or metal-molded parts.

FAQs

How to verify precision moulded components supplier reliability?

Confirm ISO 9001 status and review documented quality control procedures. Request samples to assess dimensional accuracy and surface finish. Analyze reorder rates and on-time delivery percentages as behavioral indicators of performance consistency. Video audits of production floors can validate in-house capabilities.

What is the typical lead time for custom molded components?

Mold development takes 15–30 days depending on complexity. Sample production follows within 5–7 days after mold completion. Mass production lead times range from 25 to 45 days, with faster turnaround for existing mold designs.

Can suppliers provide material certifications?

Yes, reputable manufacturers supply material test reports (MTRs) for resins and metals upon request. For regulated industries, confirm availability of RoHS, REACH, or UL compliance documentation prior to order placement.

Do suppliers support small orders and prototypes?

Most listed suppliers accept MOQs of 1 piece, allowing prototype testing and iterative design validation. Unit prices decrease significantly at volumes above 1,000 units due to amortized mold costs.

How to initiate a customization request?

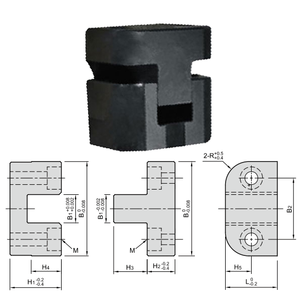

Submit detailed technical specifications including 2D/3D CAD files, material requirements, tolerance levels, surface finish preferences, and intended application. Suppliers typically respond with design for manufacturability (DFM) feedback within 48 hours.