Precision Moulds And Components

About precision moulds and components

Where to Find Precision Moulds and Components Suppliers?

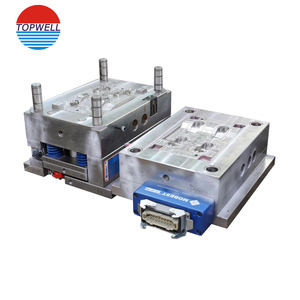

China remains a global hub for precision moulds and components manufacturing, with key industrial clusters in Guangdong, Zhejiang, and Dongguan offering specialized capabilities. These regions host vertically integrated facilities combining advanced CNC machining, injection moulding, and die-casting processes under one ecosystem. Guangdong, particularly Shenzhen, excels in high-precision plastic injection moulds for consumer electronics and automotive sectors, supported by rapid prototyping infrastructure and proximity to polymer supply chains.

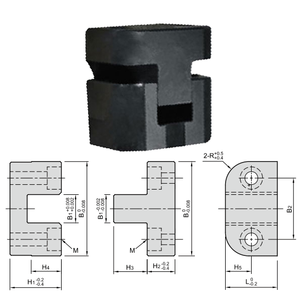

Zhejiang-based suppliers like Ningbo focus on compound dies and hardened steel tooling, leveraging localized metallurgical expertise to achieve tight tolerances (±0.005mm). Dongguan integrates metal stamping and plastic moulding services, enabling hybrid component production for industries such as solar energy and medical devices. The regional clustering allows buyers to access co-located material suppliers, heat treatment providers, and logistics networks within 30–50km radii, reducing lead times by up to 25% compared to decentralized sourcing models.

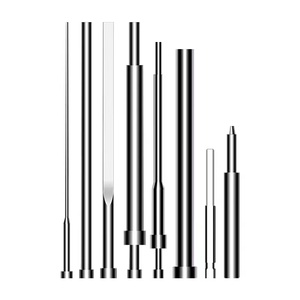

Monthly production capacities among mid-tier suppliers range from 80–150 mould sets, with cycle times optimized through automated polishing and EDM (Electrical Discharge Machining) systems. Materials commonly used include P20, 718H, NAK80 steels, and aluminum alloys, selected based on durability requirements and part complexity. This concentrated manufacturing base supports both low-volume custom tooling and high-volume component runs with MOQs starting from 1 piece or set.

How to Choose Precision Moulds and Components Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Prioritize suppliers with ISO 9001 certification as a baseline for documented quality management systems. For export markets requiring regulatory compliance, verify CE or RoHS declarations—particularly critical for electronic housings and medical-grade parts. Request inspection reports covering hardness testing (HRC 48–52 standard), surface finish (Ra ≤ 0.8μm), and dimensional accuracy validation via CMM (Coordinate Measuring Machine).

Production Capability Verification

Assess core competencies through the following indicators:

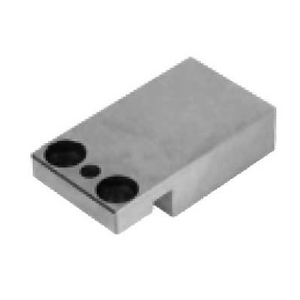

- In-house machining capacity including CNC, wire-cut EDM, and grinding equipment

- Design-to-production workflow with support for 2D/3D drawings (STEP, IGES, DWG formats)

- Customization scope: material selection, color coding, labeling, packaging configurations

Cross-reference online revenue data and reorder rates as proxies for market acceptance and reliability. Target suppliers with ≥93% on-time delivery performance and response times under 3 hours.

Procurement Safeguards

Utilize structured sampling protocols before full-scale orders. Confirm mold trial procedures, including T0 (initial sample), T1 (first approval), and final validation stages. Use secure payment terms—preferably milestone-based disbursements tied to prototype approval and shipment. Validate intellectual property protection measures if proprietary designs are shared during customization.

What Are the Best Precision Moulds and Components Suppliers?

| Company Name | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| TECH PLASTIC MOLD CO.,LIMITED | Custom Manufacturer | Injection moulds, automotive components | US $140,000+ | 100% | 40% | ≤2h | Color, size, logo, packaging, graphic | 1 set |

| Dongguan Tongsheng Metal Technology Co., Ltd. | Multispecialty Supplier | Stamping dies, solar connector molds | US $30,000+ | 93% | 27% | ≤2h | Color, material, size, logo, packaging | 1 piece/set |

| Ningbo Sail Tool Technology Co., Ltd. | Manufacturer | Single-operation compound dies | US $80,000+ | 100% | 100% | ≤2h | Limited (product-focused) | 1 set |

| Sando Technology Co., Ltd. | Manufacturer | Precision injection molds, plastic parts | US $150,000+ | 100% | 45% | ≤1h | Moderate | 1 piece |

| Shenzhen Shunheng Precision Mould Co., Ltd. | Brand Holder | Plastic gears, injection molding parts | US $100,000+ | 100% | <15% | ≤3h | Extensive: drawings, weight, material, design | 1 piece |

Performance Analysis

TECH PLASTIC MOLD CO., LIMITED and Sando Technology demonstrate strong commercial traction with high online revenues and responsive service (≤2h and ≤1h average responses). Sando leads in transaction efficiency, combining top-tier responsiveness with a robust $150,000+ digital sales volume. Ningbo Sail stands out for customer retention, achieving a 100% reorder rate—indicative of consistent output quality and long-term client satisfaction despite narrower product customization options.

Shenzhen Shunheng offers extensive engineering-level customization but exhibits lower repeat order activity, suggesting niche positioning or longer sales cycles. Dongguan Tongsheng provides broad material and color flexibility at competitive pricing tiers ($0.10/unit), though its 93% on-time delivery rate slightly lags behind peers. Buyers seeking high-volume consistency should prioritize suppliers with 100% on-time records and dedicated R&D support for complex geometries.

FAQs

What is the typical lead time for precision mould production?

Standard mould fabrication takes 25–45 days depending on complexity. Simple single-cavity tools require 2–3 weeks, while multi-cavity or two-shot (2K) moulds extend to 6–8 weeks. Add 7–14 days for international shipping via air freight or 25–35 days for sea container transit.

Are samples available before mass production?

Yes, most suppliers provide pre-production samples after mould completion. Sample costs may be waived upon confirmation of full orders, especially for contracts exceeding 5,000 units. Expect unit prices ranging from $0.10–$1.00 for initial test runs.

Can suppliers handle full project lifecycle from design to delivery?

Leading manufacturers offer end-to-end services including CAD/CAM design, mould flow analysis, material sourcing, injection molding, post-processing (e.g., painting, assembly), and drop-shipping. Confirm availability of 3D rendering and DFM (Design for Manufacturability) feedback within 72 hours of inquiry submission.

What are common MOQs for precision components?

MOQs vary: moulds typically require 1 set minimum, while component orders start at 1,000–5,000 pieces for economical unit pricing. Some suppliers accept trial batches of 100–500 units at higher per-unit costs.

How to assess tooling longevity and maintenance support?

Inquire about expected mould life cycles (typically 100,000–500,000 shots for P20 steel, up to 1M shots for hardened alloys). Reputable suppliers provide maintenance guidelines, spare part availability, and reconditioning services. Request wear-test documentation and cavity pressure monitoring data where applicable.