Protective Net For Bottles Factories

CN

CN

About protective net for bottles factories

Where to Find Protective Net for Bottles Factories Suppliers?

China remains the dominant manufacturing hub for protective nets used in bottle packaging, with key production clusters concentrated in Jiangsu, Hebei, and Guangdong provinces. These regions host vertically integrated extrusion facilities specializing in polyethylene (PE) mesh netting, foam sleeves, and stretchable tubing designed for glass and plastic container protection during transit and storage. Suzhou and Foshan serve as primary centers for custom PE net production, leveraging localized polymer supply chains and automated braiding lines to achieve high-volume output at competitive costs.

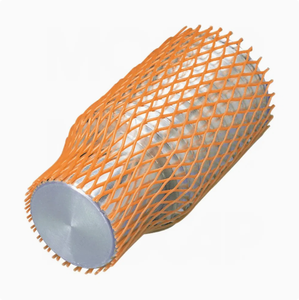

The industrial ecosystem supports both standard and engineered solutions, with suppliers utilizing blown-film extrusion and circular knitting technologies to produce elastic, lightweight nets that expand to fit various bottle diameters. Integration with downstream printing, cutting, and packaging units enables rapid turnaround for customized orders. Buyers benefit from proximity to raw material sources—particularly LDPE and LLDPE resins—which reduces input costs by 15–20% compared to non-specialized regions. Average lead times range from 15 to 30 days for bulk shipments, with express processing options available for urgent requirements.

How to Choose Protective Net for Bottles Factories Suppliers?

Evaluate potential partners using the following criteria to ensure product quality, reliability, and scalability:

Material & Process Compliance

Confirm use of food-grade or industrial-grade polyethylene meeting relevant safety standards such as FDA 21 CFR or RoHS for export markets. Insist on documentation verifying raw material sourcing and batch testing for tensile strength, elasticity, and UV resistance where applicable. Suppliers should demonstrate control over extrusion parameters including die design, blow-up ratio, and cooling rates to maintain consistent mesh density.

Production Capacity Verification

Assess operational scale through verifiable metrics:

- Minimum monthly output capacity exceeding 50 metric tons

- In-house capability for dyeing, slitting, printing, and roll winding

- Custom tooling support for diameter adjustment (typically 50–150mm expandable range)

Cross-reference supplier claims with order fulfillment history, targeting those with on-time delivery rates above 97% and reorder rates exceeding 25%.

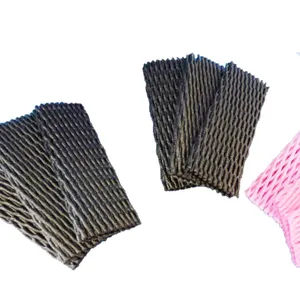

Customization and Transaction Security

Prioritize suppliers offering full customization of color, size, logo imprinting, and packaging format (rolls, pre-cut pieces, bags). Require digital proofs or physical samples before mass production. Utilize secure payment methods with escrow functionality to mitigate risk, particularly when engaging newer manufacturers. Validate company credentials through business licenses and third-party trade assurance records.

What Are the Best Protective Net for Bottles Factories Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Suzhou Yitengjia Extruded Net Packaging Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $420,000+ | 100% | ≤2h | 33% | Color, material, size, logo, packaging, label, rolls, graphic, meters | 500 kg |

| Hebei Tengfei Wire Mesh Co., Ltd. | Hebei, CN | Custom Manufacturer | US $430,000+ | 100% | ≤2h | 27% | Color, material, size, logo, packaging, label, rolls, graphic | 50–2000 rolls/pieces |

| Foshan Huixin Packaging Materials Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $60,000+ | 97% | ≤2h | 31% | Material, size | 100–150,000 pieces |

| Laizhou Demeter Imports And Exports Co., Ltd. | Shandong, CN | - | US $20,000+ | 100% | ≤1h | - | Limited public data | 1,000–100,000 pieces |

| Laizhou Guoliang Packing Products Co., Ltd. | Shandong, CN | Custom Manufacturer | US $4,000+ | 50% | ≤5h | <15% | Color, size, logo, packaging, label, graphic | 10,000–300,000 pieces |

Performance Analysis

Suzhou Yitengjia and Hebei Tengfei lead in verified performance, combining high revenue volume, 100% on-time delivery, and extensive customization capabilities. Hebei Tengfei offers one of the lowest per-unit prices ($0.01–$0.05), making it ideal for high-volume buyers. Suzhou Yitengjia’s pricing is structured by weight (from $2.20/kg), suiting clients needing continuous roll supply. Foshan Huixin provides flexibility in minimum order size, accepting as few as 100 pieces, beneficial for sampling or niche applications. Laizhou-based suppliers show mixed reliability—while Demeter excels in responsiveness (≤1h), Guoliang lags with only 50% on-time delivery, indicating potential operational constraints. For mission-critical procurement, prioritize suppliers with proven track records, scalable infrastructure, and comprehensive quality controls.

FAQs

What materials are commonly used in protective bottle nets?

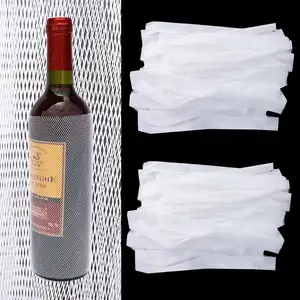

Polyethylene (PE), particularly low-density PE (LDPE), is the standard material due to its elasticity, durability, and cost efficiency. Some variants incorporate EPE foam for enhanced cushioning in premium wine or liquor packaging.

What is the typical MOQ for protective bottle nets?

MOQs vary significantly: extruded netting sold by weight starts at 500 kg, while pre-cut sleeves or rolls may require 50 to 300,000 pieces depending on supplier scale and production setup.

Can suppliers customize the net color and print branding?

Yes, most established manufacturers support Pantone-matched coloring and logo printing via flexographic or digital methods. Custom dies and printing plates may incur setup fees for small batches.

How long does sample production take?

Standard samples ship within 5–7 days; customized versions with specific dimensions or graphics require 10–15 days. Air freight adds 3–7 days for international delivery.

Are protective bottle nets recyclable?

Yes, PE-based nets are fully recyclable under resin identification code #4 (LDPE). Buyers seeking sustainable packaging should confirm recyclability certifications and avoid mixed-material composites unless specified.