Protective Net For Windows Factory

1/3

1/3

1/38

1/38

1/3

1/3

1/18

1/18

1/21

1/21

1/3

1/3

1/3

1/3

1/8

1/8

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/2

1/2

0

0

1/27

1/27

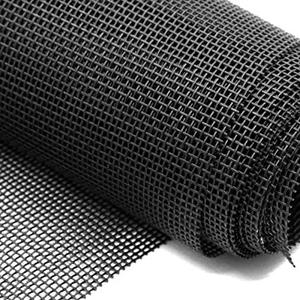

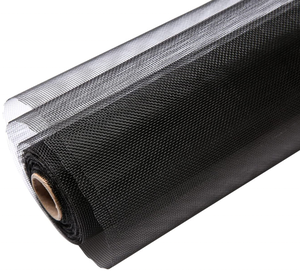

About protective net for windows factory

Where to Find Protective Net for Windows Factory Suppliers?

China remains the dominant hub for protective window net manufacturing, with Anping County in Hebei Province serving as the primary industrial cluster. Known globally for wire mesh and safety net production, Anping hosts hundreds of specialized factories equipped with integrated extrusion, weaving, and coating lines. These suppliers leverage localized access to raw materials—such as HDPE, nylon, aluminum, and fiberglass—reducing input costs by 15–25% compared to non-specialized regions.

The region’s mature supply chain ecosystem enables rapid prototyping and scalable production, supporting both standard roll-based orders and custom-engineered solutions. Most manufacturers operate vertically integrated facilities capable of handling material processing, mesh fabrication, anti-UV treatment, and packaging in-house. This integration supports lead times averaging 15–25 days for bulk orders, with some suppliers offering express production within 7–10 days for urgent shipments. The proximity of logistics hubs in Shijiazhuang and Tianjin further enhances export efficiency to North America, Europe, and Southeast Asia.

How to Choose Protective Net for Windows Factory Suppliers?

Procurement decisions should be guided by a structured evaluation framework focusing on technical capability, quality assurance, and transactional reliability.

Production Capacity Verification

Assess whether suppliers possess dedicated production lines for key materials: extruded plastic nets (HDPE/PP), woven stainless steel meshes, or coated fiberglass screens. Minimum viable factory size for consistent output exceeds 3,000m², with automated braiding and heat-setting systems indicating higher process control. Prioritize suppliers listing “own production line” in product keywords, as this confirms direct manufacturing oversight rather than trading intermediation.

Material & Technical Specifications

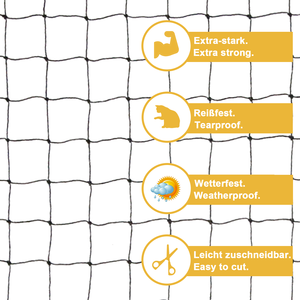

Evaluate offerings across critical parameters:

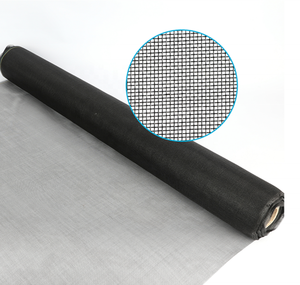

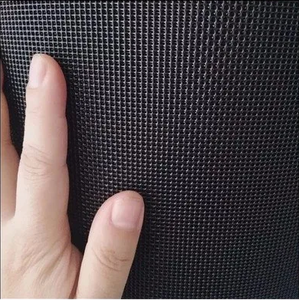

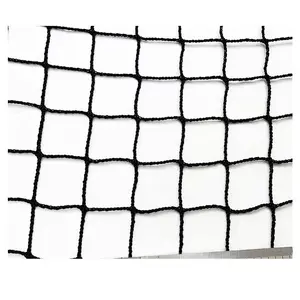

- Mesh density (measured in threads per inch, e.g., 18x16)

- Wire diameter (0.2–0.4mm for aluminum; up to 0.6mm for steel)

- Tensile strength (>150N for child/pet safety applications)

- UV stabilization for outdoor durability (minimum 3-year weather resistance)

- Fire retardancy compliance (e.g., ASTM E84 Class 1)

Cross-reference product listings with available customization options, including cut-to-size dimensions, magnetic frame integration, adhesive backing, or color-specific pigmentation (black, white, gray standard).

Quality Management & Compliance

While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates (target ≥98%) and documented response times (≤2 hours) serve as proxy indicators of operational discipline. For EU and North American markets, verify RoHS and REACH compliance for plastic components, and ensure fiberglass products meet EN 13541 standards for solar shading and mechanical resilience. Request test reports for tear resistance, flame spread, and salt spray corrosion (for metal variants).

Transaction Security & Sampling

Utilize secure payment mechanisms such as escrow services where funds are released post-inspection. Require physical or digital samples before full-scale ordering—most suppliers accommodate sample requests at 1.5–2x unit price, with minimums ranging from 1m² to 5 units. Confirm packaging specifications (individual polybags, master cartons, palletization) and labeling requirements for retail or B2B distribution.

What Are the Best Protective Net for Windows Factory Suppliers?

| Company Name | Main Materials | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Customization | Verified Capability |

|---|---|---|---|---|---|---|---|

| Anping Yuda Wire Mesh Co., Ltd. | Stainless Steel, Aluminum, Plastic | 50 m² / 50 pcs | $0.25–3.02 | 100% | ≤2h | Limited | Own Production Line |

| Anping Yuansheng Mesh Co., Ltd. | Aluminum, Fiberglass, Plastic | 1–1000 m² | $0.35–7.48 | 100% | ≤6h | Extensive (color, size, logo, frame) | Custom Manufacturer |

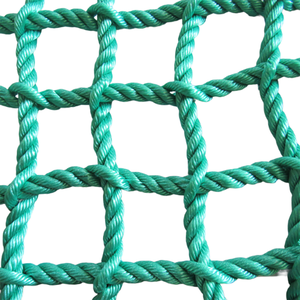

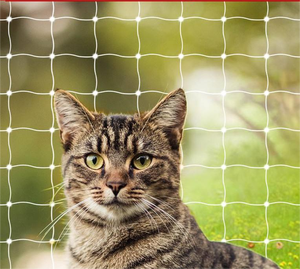

| Anping Weicai Wire Mesh Products Co., Ltd. | Nylon, HDPE + Metal Core | 10–100 units | $6.50–50.00 | 100% | ≤2h | Moderate (anti-cat, balcony safety) | Own Production Line |

| Wuqiang County Hong Hai Glass Fiber Co., Ltd. | Fiberglass, PVC-Coated | 3000 m² | $0.15–0.29 | 100% | ≤1h | High (roll specs, mesh size, packaging) | Custom Manufacturer |

| Hebei Hengjiaxin Fiberglass Manufacturer Co., Ltd. | Fiberglass, Plastic | 30–1000 m² | $0.21–1.45 | 100% | ≤2h | Basic (color, size, label) | Custom Manufacturer |

Performance Analysis

Wuqiang County Hong Hai Glass Fiber leads in cost efficiency for high-volume buyers, offering sub-$0.20/m² pricing at MOQs of 3,000m², supported by ultra-fast response times. Anping Yuansheng Mesh distinguishes itself through extensive customization capabilities, enabling branded packaging, magnetic closures, and tailored frame heights—ideal for OEM partnerships. Anping Weicai focuses on premium safety applications (child/pet protection), commanding higher prices ($6.50–$50/unit) but delivering engineered solutions with reinforced stitching and load-tested nylon. Hebei Hengjiaxin and Anping Yuda provide balanced portfolios across material types, suitable for diversified procurement strategies. All top-tier suppliers maintain 100% on-time delivery records, underscoring reliable operational execution despite varying scale.

FAQs

What materials are commonly used in protective window nets?

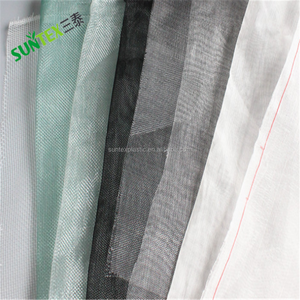

The most prevalent materials include fiberglass (lightweight, insect-resistant), HDPE/nylon (durable, UV-stabilized for balconies), stainless steel (anti-theft, high tensile strength), and aluminum (corrosion-resistant, low visibility). Material selection depends on application: fiberglass for ventilation and screening, nylon-HDPE composites for pet safety, and metal meshes for security.

What is the typical MOQ for factory-direct orders?

Minimum order quantities vary by supplier and material. Roll-based products (fiberglass, plastic) typically require 30–3,000m². Pre-cut panels or safety nets range from 10 to 100 units. Custom designs may impose higher thresholds (e.g., 70,000m² for specialty pet mesh).

Can suppliers provide fire-retardant or UV-resistant nets?

Yes, many manufacturers offer UV-stabilized HDPE and flame-retardant fiberglass treatments. These enhancements extend service life in outdoor environments and comply with building safety codes in regulated markets. Request test certificates for UV aging (ASTM G154) and flammability ratings (UL 94).

Do suppliers support private labeling and OEM packaging?

Multiple suppliers—including Anping Yuansheng and Wuqiang Hong Hai—offer full customization of packaging labels, logos, and carton design. Minimum branding requirements typically start at 1,000m² or 100 units, depending on complexity.

How long does production and shipping take?

Production lead time averages 15–25 days after sample approval. Air freight delivers samples in 5–7 days; sea freight for full containers takes 20–35 days depending on destination port. Expedited production (7–10 days) is available from select suppliers at a premium.