Prototype Shops

1/49

1/49

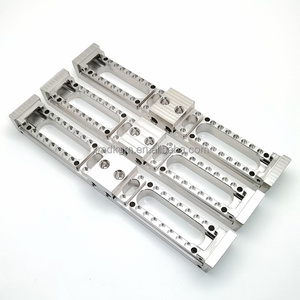

1/17

1/17

1/17

1/17

1/17

1/17

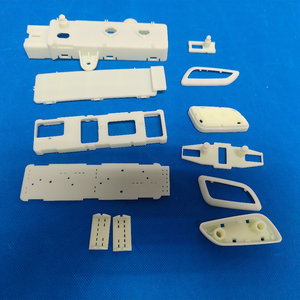

1/30

1/30

1/8

1/8

1/29

1/29

1/24

1/24

1/58

1/58

1/55

1/55

1/27

1/27

About prototype shops

Where to Find Prototype Shops Suppliers?

China remains a dominant hub for rapid prototyping services, with key manufacturing clusters in Shenzhen, Dongguan, and Qingdao offering specialized capabilities in CNC machining, 3D printing, and sheet metal fabrication. These regions host vertically integrated facilities that combine design engineering, material sourcing, and precision manufacturing under one roof, enabling agile development cycles for global clients. Shenzhen and Dongguan stand out for high-mix, low-volume production, supporting fast turnaround times (typically 5–10 days) and flexible customization.

The industrial ecosystem benefits from proximity to raw material suppliers and component vendors, reducing lead times and logistics costs. Many prototype shops operate ISO-certified environments and maintain in-house tooling, post-processing, and quality inspection units. This integration supports end-to-end project management—from CAD submission to finished prototype delivery—while ensuring consistency across iterations. Buyers gain access to scalable solutions suitable for both functional testing and pre-production validation.

How to Choose Prototype Shops Suppliers?

Effective supplier selection requires a structured evaluation of technical capability, quality assurance, and operational responsiveness:

Technical & Process Capabilities

Verify availability of core prototyping technologies: multi-axis CNC machining (up to 5-axis), SLA/SLS 3D printing, vacuum casting, and sheet metal bending. Preferred suppliers offer hybrid manufacturing pathways, combining additive and subtractive methods for complex geometries. Confirm support for engineering-grade materials including aluminum alloys (6061, 7075), stainless steel (304, 316), titanium, ABS, PC, and PEEK.

Quality Management Systems

Prioritize partners with ISO 9001 certification as a baseline for process control. For medical or aerospace applications, validate compliance with ISO 13485 or AS9100 standards. Review evidence of metrology equipment (e.g., CMM, profilometers) and documented inspection protocols. RoHS compliance is essential for electronics-integrated prototypes destined for EU markets.

Customization and Lead Time Performance

Assess customization depth: surface finishes (anodizing, polishing, painting), insert molding, overmolding, and labeling options. Evaluate digital workflow integration—suppliers with automated quoting systems and real-time order tracking typically deliver faster response times (≤2 hours) and higher on-time fulfillment rates. Target suppliers achieving ≥94% on-time delivery with reorder rates above 15%, indicating customer retention and service reliability.

Transaction and Risk Mitigation

Utilize secure payment mechanisms tied to milestone verification. Request sample prototypes before full-scale engagement to assess dimensional accuracy and finish quality. Confirm packaging standards to prevent transit damage, especially for fragile or polished components. Analyze online transaction volume as an indicator of market confidence—suppliers reporting over US $40,000 in annual revenue demonstrate consistent order flow and operational stability.

What Are the Best Prototype Shops Suppliers?

| Company Name | Location | Type | Main Processes | Materials | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Kaier Wo Prototyping Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | CNC Machining, 3D Printing, Anodizing | Aluminum, PVC, Rubber, Metal Alloys | 100% | ≤2h | 40% | US $940,000+ |

| SkyReach Intelligent MFG Limited | Guangzhou, CN | Custom Manufacturer | CNC Lathe, Milling, Precision Machining | Metal Alloys, Custom Composites | 76% | ≤3h | 15% | US $20,000+ |

| 24K Investment (Qingdao) Co., Ltd. | Qingdao, CN | Service Provider | 3D Printing (SLA/SLS), Rapid Prototyping | Resin, Plastic Models | 94% | ≤2h | 20% | US $10,000+ |

| Yokan Precision Technology (Dongguan) Co., Ltd. | Dongguan, CN | Custom Manufacturer | 5-Axis CNC Milling, High-Precision Machining | Aluminum, Semiconductor-Grade Metals | 100% | ≤16h | - | - |

| YAOPENG METAL PRODUCTS CO., LIMITED | Unknown, CN | Custom Manufacturer | CNC Turning, Gear Machining, Die Casting | Brass, Stainless Steel, Aluminum | 100% | ≤2h | 16% | US $40,000+ |

Performance Analysis

Shenzhen Kaier Wo leads in scalability and customer retention, backed by a 40% reorder rate and robust online sales performance. Its broad customization portfolio—including silk screening, oxidation treatments, and impact-resistant housing—makes it suitable for consumer-facing product development. YAOPENG Metal and Yokan Precision achieve perfect on-time delivery records, though Yokan’s slower response time may affect urgent project coordination. SkyReach offers competitive pricing but lags in delivery consistency (76%), suggesting potential bottlenecks during peak demand. 24K Investment focuses on resin-based 3D printing with strong responsiveness, ideal for early-stage concept modeling.

FAQs

How to verify prototype shop supplier reliability?

Cross-check certifications (ISO 9001, ISO 13485, RoHS) through official registries. Request facility videos or virtual audits to confirm in-house capabilities. Analyze transaction metrics such as on-time delivery rate, reorder frequency, and response time for behavioral insights into operational discipline.

What is the typical prototype lead time?

Standard CNC prototypes take 5–7 days; SLA 3D printed parts can be delivered in 3–5 days. Complex assemblies or tight-tolerance components may require up to 10 days. Rush services are available from select suppliers at a premium, reducing turnaround to 48–72 hours.

Do prototype shops support small MOQs?

Yes, most suppliers listed accept minimum orders of 1 piece or 10 cm of print length, making them suitable for R&D and startup projects. Bulk pricing applies beyond 100 units, particularly for machined metal components.

Can suppliers handle full product lifecycle prototyping?

Top-tier manufacturers provide iterative development support—from initial concept models to functional prototypes and bridge production. They integrate feedback loops using GD&T documentation and first-article inspection reports to ensure alignment with final production specifications.

How are custom materials and finishes managed?

Suppliers with advanced post-processing capabilities offer anodizing (Type II/III), powder coating, bead blasting, and laser engraving. Material substitutions are evaluated based on mechanical properties and environmental resistance; technical teams typically respond within 24 hours with feasibility assessments.