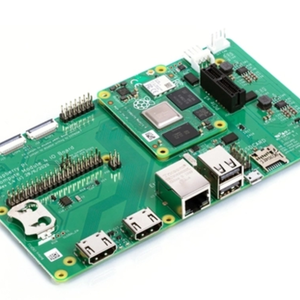

Rasp Pi 4 Pinout

Top sponsor listing

Top sponsor listing

1/3

1/3

1/7

1/7

1/28

1/28

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

1/35

1/35

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

About rasp pi 4 pinout

Where to Find Raspberry Pi 4 Pinout Suppliers?

Global sourcing for Raspberry Pi 4 pinout-compatible components and development accessories is concentrated in electronics manufacturing hubs across South China, particularly in Shenzhen and Dongguan. These regions host vertically integrated supply chains capable of producing PCBs, GPIO breakout boards, and pinout reference modules with precision tolerances. Shenzhen’s Huaqiangbei district alone supports over 80% of China’s embedded electronics component suppliers, offering rapid prototyping and low-cost assembly services.

The ecosystem enables streamlined production through co-located SMT lines, testing labs, and packaging facilities, all within a 30km radius. This proximity reduces lead times for standard pinout-related products—such as labeled GPIO headers, expansion shields, and educational kits—to 15–25 days for batch orders. Buyers benefit from 25–35% lower unit costs compared to European or North American assemblers, driven by localized access to FR4 substrates, brass pins, and silkscreen printing materials. Custom labeling, color-coded pin mapping, and multi-language documentation are routinely supported at no additional tooling cost.

How to Choose Raspberry Pi 4 Pinout Suppliers?

Adopt the following verification protocols to ensure technical accuracy and supply chain reliability:

Technical Compliance

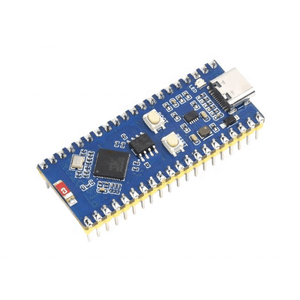

Confirm alignment with Raspberry Pi Foundation's official GPIO specifications (40-pin 2×20 layout, 2.54mm pitch, defined function mapping). Suppliers must provide pinout diagrams traceable to Revision 1.4 documentation. For CE-marked assemblies, verify RoHS compliance and IPC-A-610 Class 2 standards for solder joint integrity and insulation resistance.

Production Capability Audits

Assess operational infrastructure using these benchmarks:

- Minimum 2,000m² cleanroom facility for PCB handling and assembly

- In-house laser marking and silkscreen printing for accurate pin labeling

- Automated optical inspection (AOI) systems for defect detection

Cross-reference supplier claims with sample testing results, focusing on dimensional accuracy (±0.1mm tolerance) and electrical continuity across all 40 pins.

Transaction Safeguards

Utilize secure payment terms such as irrevocable LC or escrow until product validation is complete. Request pre-shipment inspection reports from third-party auditors (e.g., SGS or TÜV) covering material traceability, labeling correctness, and packaging durability. Sample evaluation is critical—test at least two units per batch for signal interference, cross-talk, and mechanical fit with Raspberry Pi 4B/400 models before scaling procurement.

What Are the Best Raspberry Pi 4 Pinout Suppliers?

No verified supplier data is currently available for dedicated "Raspberry Pi 4 pinout" manufacturers. The market primarily consists of electronics assemblers and accessory producers that integrate pinout designs into broader product lines such as GPIO expansion boards, HATs, and educational kits. As such, buyer due diligence must focus on engineering precision, documentation fidelity, and compatibility verification rather than standalone supplier rankings.

Performance Analysis

In absence of structured supplier listings, procurement success depends on technical validation and prototype iteration. Leading-tier manufacturers differentiate through adherence to Raspberry Pi’s open hardware guidelines, offering revision-controlled documentation and version-specific labeling. Buyers should prioritize partners who publish test reports, support schematic sharing, and allow remote factory audits via video walkthroughs of SMT and QC stations. Emphasis should be placed on error-proofing measures—such as keyed connectors and color-coded silkscreens—to prevent miswiring in end-user applications.

FAQs

How to verify Raspberry Pi 4 pinout supplier reliability?

Validate technical drawings against the official pinout schema from raspberrypi.com. Request evidence of prior shipments to Tier-1 distributors or OEMs. Conduct on-site or virtual audits to confirm ESD-safe handling, calibration logs for measuring equipment, and traceability of base materials (e.g., halogen-free PCBs).

What is the average sampling timeline?

Standard samples take 7–14 days to produce, including silkscreen application and continuity testing. Custom variants with bilingual labeling or modified footprints require 18–25 days. Air freight adds 5–9 days for international delivery.

Can suppliers ship globally?

Yes, most manufacturers support worldwide distribution under FOB Shenzhen or CIF destination terms. Confirm UN38.3 certification for lithium battery inclusion (if applicable) and proper HS code classification (typically 8536.69 or 8542.31) to avoid customs delays.

Do suppliers provide free samples?

Sample policies vary. First-time buyers typically pay full sample cost plus shipping. Fee waivers may apply if subsequent orders exceed 500 units. Reimbursement programs are occasionally offered upon contract signing.

How to initiate customization requests?

Submit detailed requirements including board dimensions, pin labeling language (e.g., English/Chinese), silkscreen colors, and special features like anti-reversal keys or mounting holes. Suppliers with CAD/CAM integration can return Gerber files and 3D STEP models within 72 hours for approval prior to fabrication.