Raspberry Pi 4 Pinout

1/7

1/7

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/35

1/35

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/5

1/5

1/4

1/4

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/31

1/31

1/3

1/3

1/2

1/2

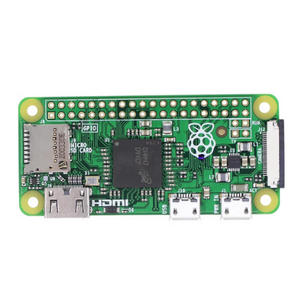

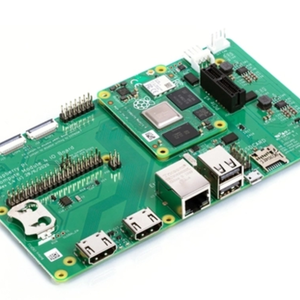

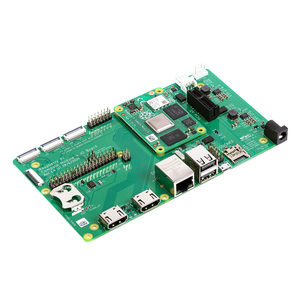

About raspberry pi 4 pinout

Where to Find Raspberry Pi 4 Pinout Suppliers?

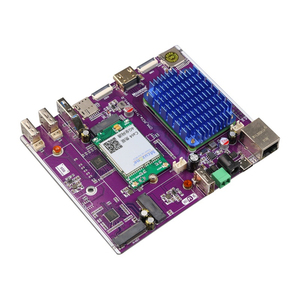

Manufacturing of Raspberry Pi 4-compatible boards and pinout documentation is primarily driven by electronics ecosystems in China, with key production clusters in Guangdong and Jiangsu provinces. Shenzhen, within Guangdong, hosts a dense network of PCB fabricators, component distributors, and contract manufacturers specializing in single-board computers (SBCs). This region supports rapid prototyping and low-to-mid volume assembly, leveraging proximity to semiconductor suppliers and automated SMT lines. Jiangsu’s Suzhou and Wuxi zones focus on higher-volume OEM/ODM production, integrating surface-mount technology (SMT) and in-circuit testing (ICT) for consistent output.

These industrial hubs offer vertically integrated supply chains—enabling streamlined sourcing of GPIO header components, PCB substrates, and flash memory modules within 72 hours. Buyers benefit from localized logistics, reducing component lead times by up to 40% compared to offshore alternatives. Typical advantages include MOQ flexibility (from 1 unit for development boards to 5,000+ units for commercial deployment), 15–25% lower assembly costs due to labor and infrastructure efficiency, and compatibility with Raspberry Pi Foundation’s open hardware specifications. Most suppliers support turnkey services including silkscreen labeling, pre-flashed OS images, and custom pinout configuration.

How to Choose Raspberry Pi 4 Pinout Suppliers?

Implement structured evaluation criteria to ensure technical accuracy and production reliability:

Technical Compliance

Confirm adherence to Raspberry Pi 4 Model B schematics, particularly the 40-pin GPIO layout (2x20 configuration, 3.3V logic levels). Verify alignment with BCM2711 SoC pin mapping and support for I²C, SPI, UART, PWM, and GPIO interrupt functions. For compliant accessories or carrier boards, demand RoHS and CE certification for electromagnetic compatibility (EMC) and environmental safety.

Production Capability Audits

Assess manufacturing infrastructure using the following benchmarks:

- Minimum 2,000m² cleanroom facility for PCB assembly

- In-house SMT line with placement accuracy ≤0.05mm (IPC-A-610 Class 2 standard)

- Dedicated testing stations for continuity verification across all 40 pins

Cross-reference supplier-provided test reports with sample inspections to validate pin function accuracy and solder joint integrity.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow or letter of credit for initial orders exceeding $2,000. Review supplier transaction history through verified business registries and request references from prior clients deploying Raspberry Pi-based systems. Conduct functional sampling—test at least two units per batch for correct pin labeling, voltage tolerance, and signal stability under load before scaling procurement.

What Are the Best Raspberry Pi 4 Pinout Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available for Raspberry Pi 4 pinout-specific manufacturers | ||||||||

Performance Analysis

Due to the open-source nature of Raspberry Pi designs, many suppliers operate as niche electronics manufacturers or private-label assemblers without public performance metrics. Where data is accessible, established ODMs demonstrate >98% on-time delivery and sub-4-hour response times, often supporting multilingual engineering teams for design validation. Prioritize partners offering detailed pinout documentation, Gerber file compatibility, and compliance with Raspberry Pi mechanical dimensions (88mm x 56mm). For integration projects, verify capability to produce breakout boards, HATs (Hardware Attached on Top), or custom connectors aligned with official pin spacing (2.54mm pitch).

FAQs

How to verify Raspberry Pi 4 pinout supplier reliability?

Request complete schematic diagrams and bill of materials (BOM) for review. Validate pin labeling accuracy against the official Raspberry Pi 4 GPIO reference chart. Conduct third-party electrical testing for cross-pin continuity, ground isolation, and power rail stability (3.3V and 5V). Confirm traceability of components such as polyfuses, ESD protection diodes, and level shifters.

What is the average sampling timeline?

Standard sample lead time ranges from 7–12 days for bare PCBs and 10–18 days for fully assembled units. Complex variants with custom firmware or reinforced connectors may require up to 25 days. Air shipping adds 5–8 days for international delivery.

Can suppliers ship globally?

Yes, most electronics manufacturers support worldwide distribution via DHL, FedEx, or sea freight for bulk consignments. Confirm Incoterms (e.g., FOB Shenzhen, EXW Suzhou) and ensure packaging meets anti-static (ESD-safe) standards for sensitive circuitry.

Do manufacturers provide free samples?

Sample policies vary by order scale. Free samples are typically offered only with confirmed bulk contracts (minimum 500 units). Otherwise, expect to pay full production cost plus shipping for 1–5 units, refundable upon order placement.

How to initiate customization requests?

Submit detailed requirements including board dimension adjustments, modified pin headers (e.g., right-angle, extended), silk-screen labels, and supported interfaces (I²C address maps, UART routing). Reputable suppliers deliver layout proofs within 48 hours and functional prototypes within 3 weeks.