Shutter Making Machine Price In India

Top sponsor listing

Top sponsor listing

CN

CN

About shutter making machine price in india

Where to Find Shutter Making Machine Suppliers?

China remains the dominant global hub for shutter making machine manufacturing, with key production clusters in Hebei and Shandong provinces. These regions host vertically integrated facilities specializing in cold roll forming technology, steel processing, and automated assembly lines. Hebei, particularly cities like Cangzhou and Dongguan, concentrates over 70% of China’s construction material machinery exporters, offering proximity to Tianjin Port—one of Asia’s busiest logistics gateways—reducing export lead times by up to 25%. Shandong-based manufacturers leverage access to high-grade steel mills, enabling cost reductions of 18–22% on raw materials compared to international suppliers.

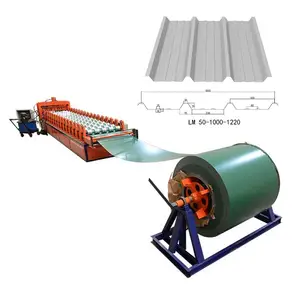

The industrial ecosystem supports rapid prototyping and scalable production, with most suppliers operating end-to-end workflows from decoiling and leveling to roll forming, punching, and cutting. This integration allows standard orders to be fulfilled within 30–45 days, while customized configurations typically require 45–60 days. Buyers benefit from competitive pricing due to economies of scale, localized component sourcing, and mature supply chains encompassing electrical controls, hydraulic systems, and precision rollers—all within a 50km radius of major factories.

How to Choose Shutter Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Prioritize suppliers with demonstrated expertise in cold roll forming technology and metal fabrication. Key indicators include:

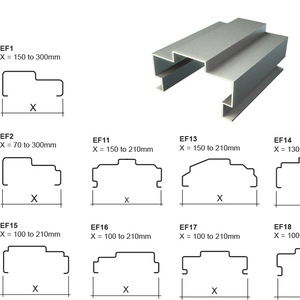

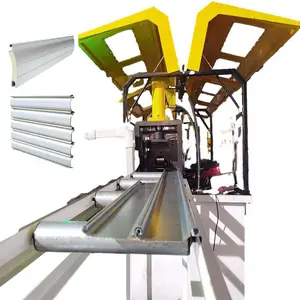

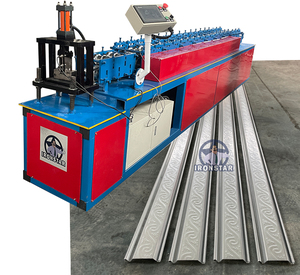

- In-house engineering teams capable of customizing profile designs, slat thickness (0.3–2.0mm), and coil width compatibility (up to 1,250mm)

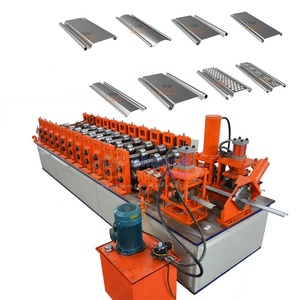

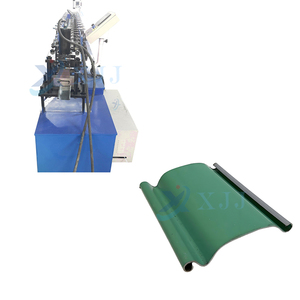

- Integrated production lines featuring decoilers, leveling systems, roll formers, punching units, and cut-off mechanisms

- Minimum factory area exceeding 3,000m² to ensure batch processing capacity

- Support for multiple material types: galvanized steel, aluminum, color-coated sheets, and insulated sandwich panels

Quality Assurance & Compliance

Verify adherence to international quality standards. While ISO 9001 certification is not universally listed, consistent on-time delivery rates above 98% and documented testing procedures indicate robust internal quality management. For European or regulated markets, confirm CE marking eligibility and compliance with mechanical safety directives. Request validation of motor efficiency ratings, structural load tests, and corrosion resistance reports for coated components.

Customization and After-Sales Support

Leading suppliers offer comprehensive customization including color coding, logo branding, packaging configuration, and control panel language options. Evaluate responsiveness—suppliers with average reply times under 4 hours are more likely to support iterative design adjustments. Reorder rates above 50% suggest strong customer satisfaction and reliable post-installation support.

Transaction Security and Sampling

Utilize secure payment methods such as escrow services to mitigate risk during initial procurement. Request functional prototypes or video demonstrations of machine operation before full-scale ordering. Sample production timelines range from 15–30 days depending on complexity, with air freight delivery adding 7–10 days internationally.

What Are the Best Shutter Making Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order | Verification Type |

|---|---|---|---|---|---|---|---|---|

| Hebei Xinnuo Roll Forming Machine Co., Ltd. | Rolling shutter door machines, roof panel equipment | US $980,000+ | 100% | ≤4h | 66% | $4,500–18,000 | 1 set | Brand Holder |

| Dongguang County Feitian Cold Roll Forming Machinery Co., Ltd. | Metal door frame, rolling shutter slats machines | US $210,000+ | 100% | ≤2h | 50% | $9,999–15,000 | 1 piece/set | Custom Manufacturer |

| Hebei Liming Stamping Form Machine Co., Ltd. | Tiling, purlin, pipe, and shutter making machinery | US $530,000+ | 100% | ≤4h | <15% | N/A (multi-product) | N/A | Multispecialty Supplier |

| Weihai Nicer House Building Materials Co., Ltd. | Wooden louver, plantation shutter machines | US $370,000+ | 98% | ≤2h | <15% | $1,000–3,000 | 1 set | Custom Manufacturer |

| Weihai Rosen Home Building Materials Co., Ltd. | Woodworking machinery, container houses, shutters | US $40,000+ | 100% | ≤3h | 20% | $1,280–9,900 | 1 unit | Unverified |

Performance Analysis

Hebei Xinnuo stands out with the highest reorder rate (66%) and broadest price coverage, indicating strong customer retention and adaptability across budget segments. Dongguang Feitian and Weihai Nicer offer faster response times (≤2h) and cater to mid-tier buyers seeking responsive communication and standardized solutions. Notably, wooden shutter machine providers like Weihai Rosen and Weihai Nicer target niche markets with lower entry costs—machines starting at $1,000—making them viable for small workshops entering the interior shutters segment.

Suppliers with "Custom Manufacturer" status demonstrate higher flexibility in design modification, material specification, and labeling, which is critical for buyers requiring brand differentiation. In contrast, multispecialty suppliers may offer broader machinery portfolios but show lower reorder rates, suggesting less specialization in shutter-specific applications.

FAQs

What is the typical price range for shutter making machines in India?

Imported shutter making machines from Chinese suppliers range from $1,000 for basic wooden shutter units to $18,000 for fully automated metal rolling shutter lines. Most mid-range industrial models fall between $5,000 and $15,000, depending on automation level, material compatibility, and output speed.

Do suppliers offer customization options?

Yes, all major suppliers provide customization in material thickness (0.3–2.0mm), slat profile design, color coding, control system interface (PLC/HMI), and branding elements such as logos and packaging labels. Custom tooling may incur additional setup fees and extended lead times.

What are common MOQ and lead time terms?

Minimum order quantity is typically 1 set or unit. Standard lead times range from 30–45 days after deposit confirmation. Customized machines may require an additional 15 days for tooling and testing. Air freight reduces shipping time to 7–10 days but increases transport costs significantly.

Can these machines process different materials?

Most metal shutter machines handle galvanized steel, aluminum, and pre-painted coils with adjustable rollers and shear blades. Wooden shutter machines are designed specifically for solid wood or MDF louvers and frames. Confirm material specifications with the supplier before procurement to avoid compatibility issues.

How to verify machine performance before purchase?

Request live video demonstrations of the running machine, including feeding, forming, punching, and cutting cycles. Ask for sample production data, such as output speed (meters/minute), dimensional accuracy (±0.5mm tolerance), and noise levels. For high-value purchases, consider third-party inspection services upon shipment.