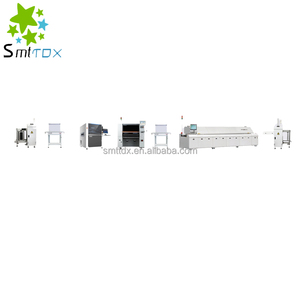

Smt Assembly Process

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

About smt assembly process

Where to Find SMT Assembly Process Suppliers?

China remains the global epicenter for SMT assembly process equipment and services, with Shenzhen emerging as a primary hub due to its dense concentration of electronics manufacturing infrastructure. The city hosts thousands of specialized firms offering everything from full SMT production lines to component-level machinery and turnkey PCBA services. This ecosystem benefits from proximity to semiconductor suppliers, contract manufacturers, and logistics networks, enabling rapid prototyping and scalable production.

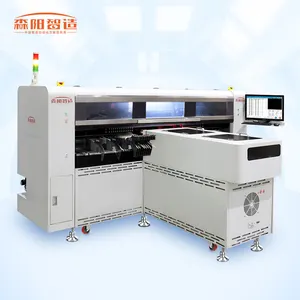

The region’s vertically integrated supply chain reduces component lead times by 20–35% compared to non-specialized markets. Buyers gain access to facilities equipped with automated pick-and-place systems, reflow ovens, solder paste printers, and AOI inspection units—all available as modular setups or complete turnkey lines. Average monthly output capacity among mid-tier suppliers exceeds 500,000 PCB assemblies, with lead times typically ranging from 15 to 30 days for standard orders. Customization is widely supported, including mixed-technology (SMT + THT) lines and retrofitting of legacy equipment.

How to Choose SMT Assembly Process Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm suppliers offer end-to-end process coverage: solder paste printing, component placement, reflow soldering, and post-assembly inspection. For full-line procurement, verify compatibility between machines (e.g., conveyor widths, interface protocols). Suppliers should provide machine specifications including placement speed (CPH), accuracy (±25–50μm), and feeder capacity. Inclusion of vision alignment systems and closed-loop feedback mechanisms indicates higher precision capability.

Quality & Compliance Standards

Prioritize suppliers adhering to IPC-A-610 for assembly quality and ISO 9001 for process control. While not always explicitly stated, RoHS compliance is standard for export-ready electronics manufacturing equipment. Request documentation on calibration procedures, preventive maintenance schedules, and defect rate tracking (target: <50 PPM).

Production Capacity & Responsiveness

Evaluate scalability through key metrics:

- Minimum facility size of 1,000m² for comprehensive line integration

- In-house engineering teams capable of system configuration and troubleshooting

- On-time delivery performance exceeding 95%

- Average response time under 4 hours for technical inquiries

Cross-reference these with reorder rates—suppliers with >25% indicate sustained customer satisfaction.

Procurement Safeguards

Utilize secure payment methods with milestone-based release terms. Conduct pre-shipment inspections either in person or via third-party audit firms. For used or refurbished equipment, demand detailed service history and functional testing reports. Sample validation is critical—test machine uptime, placement yield, and software usability before bulk purchase.

What Are the Best SMT Assembly Process Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Product Range |

|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | PCBA, Multilayer PCB, FPC, Rigid-Flex, High Frequency PCB | US $1,000+ | 100% | 66% | ≤2h | 15 products |

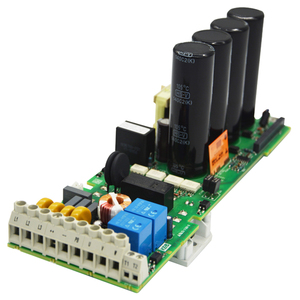

| Yueqing Qihe Electrical Technology Co., Ltd. | SMT Machines, Pick-and-Place, Screen Printers, Reflow Soldering | US $310,000+ | 100% | 25% | ≤4h | 5 products |

| Shenzhen Wenzhan Electronic Technology Co., Ltd. | SMT Lines, THT Insertion, Soldering, Cleaning Equipment | US $650,000+ | 96% | 15% | ≤2h | 5 products |

| Shenzhen Peishang Technology Co., Ltd. | SMT Pick-and-Place, Nozzles, Destackers, Used Machines | US $250,000+ | 96% | <15% | ≤1h | 5 products |

| Shenzhen Ty Electronic Technology Co., Ltd. | SMT Machines, Routers, Reflow Systems, Assembly Lines | US $2,000+ | 66% | <15% | ≤3h | 5 products |

Performance Analysis

Toptek Pcb stands out for high customer retention (66% reorder rate) and perfect on-time delivery, indicating robust internal coordination despite limited public revenue data. Yueqing Qihe matches this reliability with significantly higher online sales volume, suggesting broader market penetration in SMT machinery. Shenzhen Wenzhan offers the most expensive full-line solutions (up to $70,000), reflecting investment-grade automation capabilities. Shenzhen Peishang excels in responsiveness (≤1h average reply) and carries a diverse inventory of spare parts and used equipment, making it ideal for cost-sensitive upgrades. Conversely, Shenzhen Ty shows lower delivery reliability (66%), which may signal capacity constraints despite offering competitive pricing on compact systems.

FAQs

How to verify SMT assembly process supplier reliability?

Cross-check claimed certifications with official registries. Request references from existing clients, particularly those in similar volume brackets. Analyze transaction history for consistency in order fulfillment and dispute resolution. Video audits of factory floors and testing bays can validate operational claims.

What is the typical MOQ and pricing range?

For standalone machines, MOQ is typically 1 set, with prices ranging from $1,500 for desktop models to over $70,000 for fully automated lines. Component-level tools (e.g., nozzles) have MOQs of 1 piece. Turnkey assembly services often require minimum batch sizes of 100–500 units depending on complexity.

Can suppliers customize SMT production lines?

Yes, most suppliers support customization including line width adjustments, integration of specific feeders or vision systems, and software configuration for unique board layouts. Full custom builds typically extend lead times by 10–20 days compared to standard configurations.

Do suppliers offer after-sales support and training?

Reputable suppliers provide remote technical assistance, on-site commissioning, and operator training. Some include English-language manuals, PLC programming guides, and spare parts kits. Confirm warranty duration (typically 12 months) and availability of replacement components before purchase.

How are SMT machines packaged and shipped internationally?

Machines are crated with anti-vibration padding and moisture barriers. Sea freight is standard for full lines due to weight and dimensions. Air shipping is viable for individual units under 500kg. Buyers should confirm Incoterms (FOB vs. CIF), insurance coverage, and import clearance requirements for destination countries.