Auto Clicker Keyboard

1/3

1/3

1/24

1/24

1/3

1/3

1/4

1/4

1/3

1/3

1/3

1/3

0

0

1/16

1/16

1/25

1/25

1/3

1/3

0

0

1/9

1/9

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/14

1/14

1/3

1/3

About auto clicker keyboard

Where to Find Auto Clicker Keyboard Suppliers?

Manufacturing of auto clicker keyboards is primarily concentrated in China’s electronics and peripheral device hubs, particularly in Guangdong and Jiangsu provinces. These regions host dense clusters of OEM/ODM electronics producers with specialized expertise in human-interface devices (HID), including programmable input peripherals. Guangdong, led by Shenzhen’s advanced manufacturing ecosystem, supports rapid prototyping and high-volume production through vertically integrated supply chains for PCBs, microcontrollers, and mechanical switch components.

Suppliers in these zones benefit from proximity to Tier-1 component manufacturers, enabling reduced material lead times and lower BOM costs. The region's mature logistics infrastructure facilitates efficient export operations, with air and sea freight access streamlining global distribution. Buyers can expect standard lead times of 25–35 days for bulk orders, depending on customization level and order volume. Economies of scale allow for competitive pricing, especially for MOQs exceeding 500 units, while agile production lines support both mass production and low-volume customized variants.

How to Choose Auto Clicker Keyboard Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product reliability, compliance, and supply chain stability.

Technical Compliance

Confirm adherence to international electronics standards, including RoHS and CE certifications, to meet environmental and safety requirements in key markets such as the EU and North America. For gaming or industrial-grade models, verify EMI shielding, current draw specifications, and firmware update capabilities. Request documentation on MCU type (e.g., ATmega32U4, STM32) and polling rate performance (up to 1000Hz).

Production Capability Audits

Assess core manufacturing competencies through the following benchmarks:

- Minimum 2,000m² production area with dedicated SMT and assembly lines

- In-house PCB design and programming stations for firmware customization

- Automated testing protocols for keystroke accuracy, debounce timing, and long-cycle durability (target: 10 million+ clicks)

- R&D team participation exceeding 8% of total staff to support feature innovation and troubleshooting

Cross-reference facility size and equipment lists with historical order fulfillment data to validate scalability.

Transaction Safeguards

Utilize secure payment methods such as third-party escrow or letter of credit for initial transactions. Prioritize suppliers with verifiable export histories and documented after-sales service procedures. Pre-shipment inspections should include functional testing of sample units under real-world usage conditions. Benchmark firmware flexibility—such as macro programmability via GUI software—before full-scale ordering.

What Are the Best Auto Clicker Keyboard Suppliers?

No supplier data is currently available for detailed comparative analysis. Procurement professionals are advised to initiate due diligence by targeting manufacturers within established electronics industrial zones and validating claims through direct audits and sampling processes.

Performance Analysis

In the absence of published supplier metrics, buyers must prioritize transparent communication, technical documentation depth, and responsiveness during initial outreach. Proven track records in delivering HID devices—including custom keyboard modules—to international clients serve as strong indicators of capability. Emphasis should be placed on verifying actual production control versus trading intermediaries, particularly when sourcing programmable or low-latency models requiring precise engineering oversight.

FAQs

How to verify auto clicker keyboard supplier reliability?

Request copies of valid RoHS, CE, or FCC declarations and authenticate them through official databases. Conduct video audits of production floors to observe SMT line operations, quality checkpoints, and inventory management practices. Evaluate responsiveness and technical clarity during inquiry stages as proxies for post-sale support effectiveness.

What is the average sampling timeline?

Standard samples typically take 7–14 days to produce, depending on component availability and programming requirements. Custom firmware integration or unique housing designs may extend this to 20–25 days. Add 5–9 days for international express shipping.

Can suppliers ship auto clicker keyboards worldwide?

Yes, most established manufacturers offer global shipping via air, sea, or express courier. Confirm Incoterms (FOB, CIF, DDP) during negotiation and assess landed costs accordingly. Ensure packaging meets drop-test and moisture resistance standards for long-distance transit.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to minimum order volumes (typically 300+ units). Otherwise, expect to cover full production and shipping costs, which may be partially refunded upon order confirmation.

How to initiate customization requests?

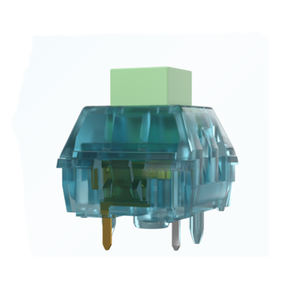

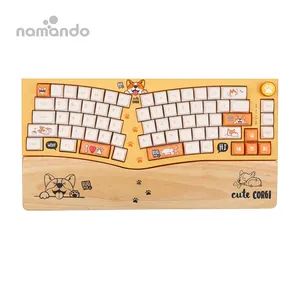

Submit detailed specifications including desired form factor, switch type (mechanical/membrane), programmable key layout, polling rate, onboard memory capacity, and preferred connectivity (USB wired, wireless 2.4GHz). Reputable partners will respond with schematic drafts, bill of materials, and prototype timelines within 5–7 business days.