Automated Electronics Assembly

CN

CN

CN

CN

1/12

1/12

1/18

1/18

1/15

1/15

CN

CN

1/4

1/4

CN

CN

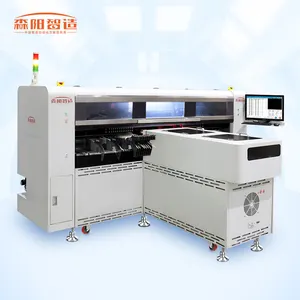

About automated electronics assembly

Where to Find Automated Electronics Assembly Suppliers?

China remains the central hub for automated electronics assembly equipment manufacturing, with key industrial clusters concentrated in Shenzhen, Dongguan, and Wenzhou. These regions host vertically integrated ecosystems that combine precision engineering, component sourcing, and advanced automation R&D within tightly connected supply networks. Shenzhen and Dongguan alone account for over 70% of China’s electronics production machinery exports, supported by proximity to semiconductor suppliers and contract manufacturers across the Pearl River Delta.

The region’s mature infrastructure enables rapid prototyping and scalable production, with many suppliers operating facilities equipped for full SMT (Surface Mount Technology) line integration, robotic pick-and-place systems, reflow soldering, and automated optical inspection. Buyers benefit from localized supply chains reducing lead times by 25–40% compared to offshore alternatives, while maintaining compliance with international standards such as CE and RoHS. Average delivery windows range from 30–60 days depending on customization level, with express assembly options available for standard configurations.

How to Choose Automated Electronics Assembly Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to ISO 9001 quality management systems as a baseline. For export to regulated markets (EU, North America), confirm CE marking and functional safety documentation. Suppliers should provide test reports for critical subsystems including motion control, vision alignment accuracy (±0.01mm typical), and thermal stability in reflow processes.

Production Capability Assessment

Evaluate core competencies through the following criteria:

- Minimum factory area of 2,000m² for dedicated assembly and testing zones

- In-house engineering teams capable of customizing feeders, nozzle sets, and conveyor interfaces

- Proven experience integrating SPI, AOI, and conveyance systems into full-line solutions

Cross-reference online transaction data with on-time delivery performance—target suppliers maintaining ≥98% fulfillment rates.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services until post-delivery validation is complete. Prioritize suppliers offering sample units or remote video demonstrations of machine operation. Conduct pre-shipment inspections to verify calibration, software interface functionality, and throughput claims (e.g., 0201 component placement speed).

What Are the Best Automated Electronics Assembly Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Sun Young Intelligent Manufacturing Equipment Co., Limited | Shenzhen, CN | SMT Fully Automatic Machinery, LED Strip Production Lines | $15,800–75,000 | 1 piece/set | 100% | ≤3h | US $500+ | - |

| Dongguan Anleji Intelligent Electronics Co., Ltd. | Dongguan, CN | Desktop SMT Pick-and-Place Machines, 4-Head Mounters | $1,450–3,699 | 1 set/plant | 100% | ≤1h | US $1,000+ | <15% |

| Shenzhen Zeyu Intelligent Industrial Science Technology Co., Ltd. | Shenzhen, CN | Custom Non-Standard Automation, Fuse & Plug Assembly Machines | $1,000–90,000 | 1 set | 100% | ≤2h | US $2,000+ | - |

| Wenzhou Yingxing Import And Export Co., Ltd. | Wenzhou, CN | PCB Assembly Lines, Reflow Soldering Systems, Screen Printers | $3,000–14,744 | 1 set | 100% | ≤5h | US $290,000+ | 30% |

| Yush Electronic Technology Co., Ltd. | Unknown, CN | SMT Assembly Lines, High-Speed PCB Handling Systems | $50,000–100,000 | 1 set | 100% | ≤5h | US $5,000+ | <15% |

Performance Analysis

Dongguan-based suppliers like Anleji offer cost-effective entry-level desktop SMT systems ideal for prototyping and low-volume production, with response times under one hour indicating strong customer service focus. Shenzhen companies such as Sun Young and Zeyu specialize in higher-end turnkey lines and custom automation, supporting complex applications in LED lighting and automotive electronics. Wenzhou Yingxing stands out with a 30% reorder rate and substantial online revenue, suggesting consistent performance and buyer trust. Yush Electronic targets high-throughput operations with large-scale SMT lines priced above $50,000, suitable for EMS providers requiring full production integration. All listed suppliers maintain perfect on-time delivery records, but differentiation lies in responsiveness, customization depth, and after-sales support capability.

FAQs

How to verify automated electronics assembly supplier reliability?

Confirm ISO certification status and request documented quality control procedures, including incoming material inspection and final system testing protocols. Analyze supplier communication patterns, response speed, and willingness to provide facility videos or live demos. Review transaction history indicators such as order frequency and dispute resolution outcomes where available.

What is the average lead time for automated assembly machines?

Standard machines ship within 30–45 days after order confirmation. Customized systems involving unique feeder configurations or software modifications require 50–70 days. Rush builds may reduce timelines by 10–15 days at additional cost.

Can suppliers accommodate OEM branding and software integration?

Yes, most established suppliers support OEM labeling and API-level integration with MES or ERP platforms. Confirm compatibility with common file formats (Gerber, CAD, CSV) and support for industry-standard communication protocols (RS-232, Ethernet/IP).

Do suppliers offer installation and training services?

Many provide remote setup guidance via video conferencing. On-site commissioning and operator training are typically offered at extra cost, ranging from $150–300 per day plus travel expenses. Some include basic training modules with purchases exceeding $20,000.

What are typical MOQs and pricing structures?

MOQ is generally one unit for standalone machines. Pricing varies significantly based on placement speed (CPH), accuracy grade, number of feeders, and software features. Entry-level desktop models start below $2,000, while fully integrated SMT lines exceed $100,000. Bulk orders may qualify for incremental discounts up to 8–12%.