Automatic Chapati Making Machine

Top sponsor listing

Top sponsor listing

About automatic chapati making machine

Where to Find Automatic Chapati Making Machine Suppliers?

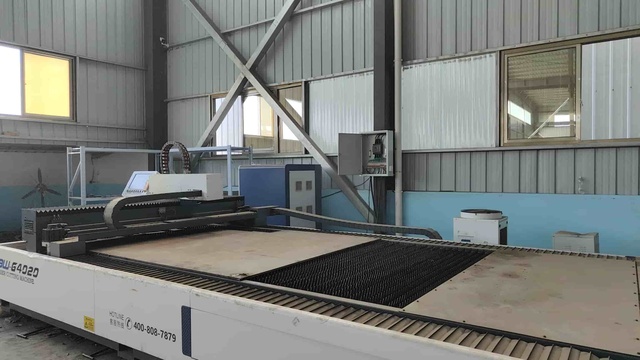

China leads global production of automatic chapati making machines, with key manufacturing clusters in Henan and Guangdong provinces. These regions host vertically integrated supply chains combining electromechanical component sourcing, food-grade material processing, and automated assembly lines. Henan’s Jiaozuo and Luohe zones specialize in compact, energy-efficient models suited for commercial kitchens, while Guangdong-based suppliers focus on high-capacity systems with advanced automation controls.

The industrial ecosystem enables rapid prototyping and scalable production, supported by localized access to stainless steel, servo motors, and food-safe conveyor belts. Suppliers benefit from proximity to Tier-1 logistics hubs, reducing export lead times by 10–15% compared to offshore competitors. Economies of scale allow for competitive pricing structures, with standard units starting below $600 and fully automated systems reaching up to $6,000 depending on output capacity and customization level. Buyers gain flexibility in order volume, with many manufacturers supporting MOQs as low as one unit for initial testing.

How to Choose Automatic Chapati Making Machine Suppliers?

Procurement decisions should be guided by the following evaluation criteria:

Technical and Food Safety Compliance

Verify adherence to international food safety standards through documentation of food-grade materials (e.g., SUS304 stainless steel contact surfaces). While formal certifications like CE or ISO 9001 are not universally declared in available data, prioritize suppliers who specify compliance with electrical safety norms (220V/110V variants) and thermal control systems. Request proof of motor insulation ratings and temperature regulation accuracy to ensure consistent dough handling.

Production and Customization Capability

Assess technical versatility based on documented customization options, including adjustable chapati diameter (typically 15–40 cm), thickness control (1–5 mm), and throughput rates (up to 1,800 pieces/hour). Key indicators of robust manufacturing include:

- In-house mold design and fabrication for shape, logo, and edge patterning

- Variable speed motor integration for dough consistency adaptation

- Modular design allowing configuration for home-use, restaurant, or industrial-scale operations

Cross-reference product listings with supplier tags indicating customization depth—such as color, packaging, label, and graphic design support—to gauge flexibility for branded deployments.

Transaction Reliability and Operational Metrics

Prioritize suppliers with verified performance metrics:

- On-time delivery rate ≥97%

- Average response time ≤2 hours

- Reorder rate transparency (suppliers with reorder rates <15% may indicate lower customer retention)

Higher online revenue indicators (e.g., US $420,000+ annual digital sales) correlate with sustained market presence and service infrastructure. Confirm scalability by reviewing main product categories—suppliers listing over 100 units in Grain Product Making Machines demonstrate domain specialization.

What Are the Best Automatic Chapati Making Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Jiaozuo Taoding Trading Co., Ltd. | Grain Product Making Machines (19453) | US $550,000+ | 97% | ≤2h | <15% | $550–5,900 | Motor, color, thickness, diameter, logo, capacity |

| Luohe Langrui Electromechanical Equipment Co., Ltd. | Grain Product Making Machines (19453) | US $420,000+ | 99% | ≤2h | <15% | $640–1,450 | Color, size, thickness, packaging, logo |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Grain Product Making Machines (19453) | US $130,000+ | 100% | ≤2h | <15% | Data not listed | Speed, mold, noise, dimensions, yield, automation |

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Other Food Processing Machinery (141) | Not disclosed | Not disclosed | ≤6h | Not disclosed | $850–3,390 | Limited customization data |

| YANN TECHNOLOGY LLC | Grain Product Making Machines (2257) | Not disclosed | Not disclosed | ≤1h | Not disclosed | $650–1,700 | Size, voltage, application-specific design |

Performance Analysis

Jiaozuo-based suppliers dominate both volume and capability, with Jiaozuo Taoding leading in price range diversity and customization depth. Luohe Langrui demonstrates strong reliability with a 99% on-time delivery rate and sub-$700 entry pricing, ideal for mid-tier commercial buyers. Jiaozuo Dingchang stands out for perfect delivery performance and extensive automation features despite limited public pricing data. YANN TECHNOLOGY exhibits fast responsiveness (≤1 hour), suggesting agile communication, though transactional metrics remain unverified. LEENOVA offers premium-priced models but lacks reorder and delivery benchmarks, increasing procurement risk without further due diligence.

FAQs

How to verify automatic chapati machine supplier reliability?

Evaluate suppliers using verifiable operational data: confirm on-time delivery rates above 97%, analyze response times under 6 hours, and assess product specialization through listing volume in core categories like Grain Product Making Machines. Request facility videos or third-party audit reports to validate production scale and quality control processes.

What is the typical lead time for orders?

Standard units typically ship within 15–30 days after order confirmation. Custom configurations involving mold design or voltage adaptation may extend lead times to 45 days. Air freight reduces delivery to 5–10 days internationally, while sea shipping takes 25–40 days depending on destination port congestion.

Can suppliers customize chapati size and shape?

Yes, most established suppliers offer adjustable diameter settings (commonly 20–30 cm, up to 40 cm), variable thickness control (1–5 mm), and custom molds for logos, patterns, and non-circular shapes. Confirm availability of food-grade silicone or stainless steel tooling before finalizing design specifications.

Do manufacturers support small or sample orders?

Yes, nearly all listed suppliers accept minimum orders of 1 unit, facilitating sample testing and pilot deployment. Some may apply higher per-unit pricing for single-unit shipments, but this provides critical evaluation opportunities for texture consistency, yield rate, and energy consumption under real operating conditions.

What are common power and voltage configurations?

Suppliers typically offer dual-voltage compatibility (110V/220V) to support North American, European, Middle Eastern, and South Asian markets. Machines are designed for single-phase or three-phase power inputs depending on capacity, with power ratings ranging from 1.5 kW to 4.5 kW for high-throughput models.