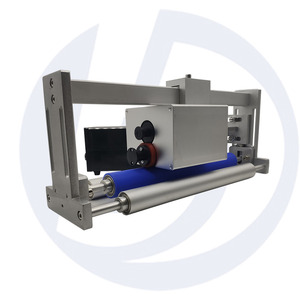

Automatic Coding Machine

About automatic coding machine

Where to Find Automatic Coding Machine Suppliers?

China remains the global epicenter for automatic coding machine manufacturing, with key production hubs in Guangdong, Hubei, and Zhejiang provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production. Dongguan and Guangzhou in Guangdong province specialize in industrial-grade inkjet and laser coding systems, leveraging proximity to electronics and automation component suppliers. Wuhan and Yiwu serve as emerging centers for compact desktop coders tailored to small-to-medium enterprises, benefiting from localized packaging machinery ecosystems.

The clustering effect enables streamlined access to precision engineering services, including CNC machining, control system integration, and fluid dynamics testing for ink delivery systems. This infrastructure supports lead times averaging 20–35 days for standard units, with customization cycles extending by 10–15 days depending on complexity. Buyers benefit from cost efficiencies driven by domestic sourcing of critical components—such as print heads and controllers—reducing overall production costs by 18–25% compared to non-Asian manufacturers.

How to Choose Automatic Coding Machine Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and electromagnetic compatibility standards, particularly CE marking for EU market access. While not explicitly stated in all profiles, CE certification is implied in product titles for export-ready models. For food, pharmaceutical, or regulated industries, ensure machines support water-resistant inks and hygienic designs compliant with GMP or FDA guidelines. Request documentation on printing resolution (typically 200–600 dpi), character height range (1–20 mm), and compatibility with variable data inputs like batch numbers, QR codes, and expiration dates.

Production and Customization Capability

Assess supplier capacity through available metrics:

- Facility scale inferred from online revenue (e.g., >US$380,000 indicates established operations)

- In-house R&D capability evidenced by diverse product variants (e.g., handheld, inline, egg-marking, conveyor-integrated)

- Customization depth—including font, logo, language, ink type (solvent-based, water-based, UV), and integration with existing packaging lines

Suppliers offering multi-nozzle systems or laser-based alternatives demonstrate higher engineering maturity. Confirm whether firmware supports date logic functions (auto-increment, Julian dating) and connectivity options (RS-232, Ethernet, USB).

Quality Assurance and Transaction Security

Prioritize suppliers with verified on-time delivery rates exceeding 95%. Real-time response times under 4 hours indicate robust customer service infrastructure. Utilize platform-backed transaction safeguards where available, especially for first-time orders. Conduct pre-shipment inspections to validate print accuracy, alignment consistency, and mechanical durability under continuous operation. Request sample outputs using your specific substrate (plastic, glass, cardboard) to assess adhesion and legibility.

What Are the Best Automatic Coding Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Offerings | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Yiwu Jeta International Trading Co,. Ltd. | Zhejiang, CN | US $220,000+ | 100% | ≤4h | <15% | Automatic high-speed inkjet coders (JT-MY380F, JT-MY300); CE-compliant models | $215–504 | 1 set |

| Maersky Logo Technology (Guangzhou) Co., Ltd. | Guangdong, CN | US $190,000+ | 100% | ≤1h | 19% | Industrial CIJ printers; egg spray coders; large-font handheld units; full-line integration | $100–2,700 | 1 piece/plant |

| Dongguan Sammi Packing Machine Co., Ltd. | Guangdong, CN | US $380,000+ | 88% | ≤2h | <15% | Desktop solid-dry ink coders; QR code printers; ribbon-based continuous systems | $120–1,000 | 1 set |

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | US $40,000+ | 96% | ≤3h | <15% | Compact inkjet coders; factory-priced entry-level systems; paging and date printers | $30.80–469 | 1 set |

| Wuhan Xiantong Technology Co., Ltd. | Hubei, CN | US $160,000+ | 100% | ≤5h | 20% | Industrial inkjet coders (Meenjet series); manual and automatic batch markers | $499–899 | 1–2 pieces |

Performance Analysis

Maersky Logo Technology stands out for responsiveness (≤1h) and broad technical scope, offering solutions from handheld coders to fully automated line-integrated systems. Yiwu Jeta and Wuhan Xiantong achieve perfect on-time delivery records, indicating reliable logistics execution. Dongguan Sammi reports the highest online revenue, suggesting strong market presence and production volume, though its 88% on-time rate warrants closer logistics scrutiny. Wuhan-based suppliers offer competitive pricing for SMEs but may lack scalability for bulk industrial deployments. Buyers seeking regulatory compliance and long-term support should prioritize suppliers with documented CE conformity and multi-language interface capabilities.

FAQs

How to verify automatic coding machine supplier reliability?

Cross-check claimed certifications (CE, ISO) through official databases or third-party verification services. Request evidence of product testing, including print endurance under high-speed line conditions (up to 200m/min). Evaluate supplier stability via transaction volume, years in operation, and customer feedback focused on after-sales technical support.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 unit, facilitating pilot testing. Standard lead times range from 15–25 days post-payment confirmation. Custom configurations involving unique fonts, communication protocols, or mounting fixtures may extend delivery by 10–15 days.

Can suppliers customize coding content and format?

Yes, nearly all listed suppliers offer customization for date formats, batch numbers, logos, barcodes, and QR codes. Advanced models support real-time database integration and dynamic content generation. Confirm software compatibility (Windows-based setup tools, Android/iOS apps) during procurement.

Do automatic coding machines support different ink types?

Reputable suppliers provide options for solvent-based, water-based, and UV-curable inks to suit substrates like PET, glass, metal, and coated cardboard. Verify ink resistance properties—especially rub, water, and fade resistance—for end-use environments.

Are samples available before bulk ordering?

Sample availability varies. Some suppliers offer functional demos at reduced cost, while others require full payment refundable against future orders. Expect sample shipping times of 5–10 days via express courier. Always test samples under actual production conditions to validate performance.