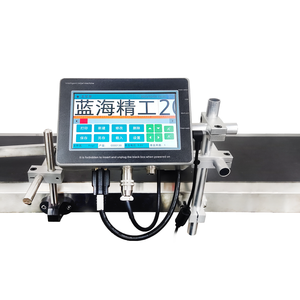

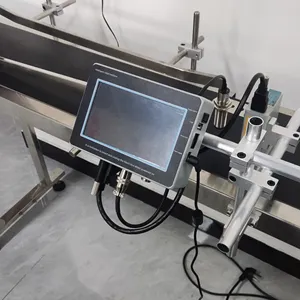

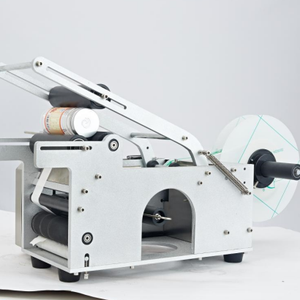

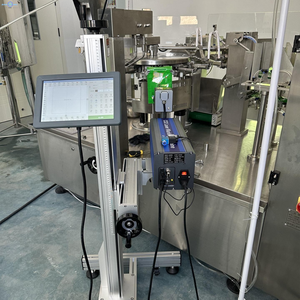

Batch Coding Machine For Bottles

About batch coding machine for bottles

Where to Find Batch Coding Machine Suppliers for Bottles?

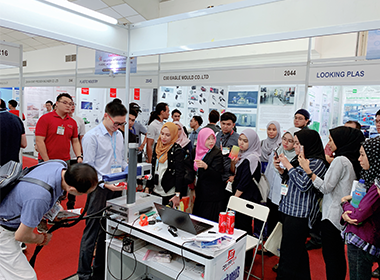

China remains the global epicenter for batch coding machine manufacturing, with key production hubs concentrated in Hubei, Guangdong, and Guangdong provinces. Wuhan, in particular, has emerged as a specialized cluster for industrial inkjet printing systems, hosting over 40% of China’s coding and marking equipment suppliers. This region benefits from deep integration with electronic component supply chains and technical R&D centers, enabling rapid prototyping and cost-efficient production.

The ecosystem supports vertically integrated operations—from printhead fabrication to full-system assembly—allowing manufacturers to maintain tight control over quality and delivery timelines. Proximity to Shenzhen’s electronics logistics network enables faster export processing, reducing shipping lead times by 7–10 days compared to inland regions. Buyers gain access to scalable production environments where standard units are delivered within 15–30 days, while customized configurations typically require 25–40 days. Cost advantages range from 20–35% below Western market averages due to localized sourcing of critical components like piezoelectric print heads and solvent-based inks.

How to Choose Batch Coding Machine Suppliers for Bottles?

Selecting reliable suppliers requires adherence to structured evaluation criteria:

Technical Capability Verification

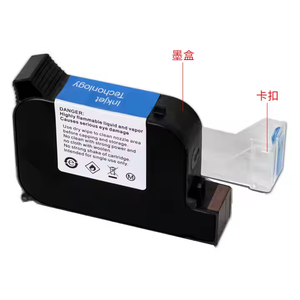

Confirm compatibility with substrate materials (PET, HDPE, glass) and environmental conditions (high humidity, oily surfaces). Essential features include variable data printing (batch codes, expiry dates, QR codes), minimum character height of 1.5mm, and operational speeds up to 200 bottles per minute. For food and pharmaceutical applications, verify use of food-grade inks compliant with FDA 21 CFR and EU Regulation No. 10/2011.

Production Infrastructure Assessment

Evaluate supplier capacity based on the following indicators:

- Minimum 3,000m² factory area supporting dedicated testing and calibration lines

- In-house engineering teams capable of customizing conveyor integration, multi-line printing, or PLC interface development

- Availability of multiple printing technologies: Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), and Hot Stamping

Cross-reference online revenue metrics and on-time delivery rates (>90%) to validate operational stability and order fulfillment consistency.

Transaction and Quality Assurance

Prioritize suppliers offering third-party inspection options and documented quality control processes. Analyze after-sales support capabilities, including remote diagnostics, spare parts availability, and firmware updates. Request sample output testing under real-world line conditions to assess print adhesion, smudge resistance, and code readability using barcode verification tools (ISO/IEC TR 29158).

What Are the Best Batch Coding Machine Suppliers for Bottles?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Wuhan Chuangjieda Industrial Co., Ltd. | Hubei, CN | Inkjet Printers (203), Printing Inks (117) | US $30,000+ | 100% | ≤2h | <15% | N/A |

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | Inkjet Printers (246), Sealing Machines (115) | US $40,000+ | 96% | ≤3h | <15% | N/A |

| Dongguan Sammi Packing Machine Co., Ltd. | Guangdong, CN | Hot Stamping, Embossing Machines | US $380,000+ | 88% | ≤2h | <15% | Color, font, ribbon, date format |

| Guangzhou Prima Technology Co., Ltd. | Guangdong, CN | CIJ Printers, TIJ Systems | US $380,000+ | 91% | ≤3h | 42% | Multi-color, sensor, nozzle size, food-grade ink |

| Wuhan Xiantong Technology Co., Ltd. | Hubei, CN | Inkjet Printers (88), Laser Marking (73) | US $160,000+ | 100% | ≤5h | 21% | N/A |

Performance Analysis

Guangzhou Prima Technology stands out with the highest reorder rate (42%), indicating strong customer retention likely driven by extensive customization options and robust CIJ system performance. Dongguan Sammi and Guangzhou Prima report the highest online revenues (US $380,000+), reflecting mature export operations and diversified product portfolios. Wuhan-based suppliers demonstrate superior responsiveness, with three companies achieving sub-3-hour average reply times and perfect on-time delivery records. While their reorder rates remain below 25%, this may reflect market positioning toward one-off or project-based buyers rather than recurring contracts. For high-volume deployments, prioritize suppliers with proven CIJ/TIJ integration experience and documented compliance with international safety standards.

FAQs

How to verify batch coding machine supplier reliability?

Cross-check technical claims with product specifications and request independent test reports for print durability, ink adhesion, and mean time between failures (MTBF). Validate supplier credentials through transaction history, response consistency, and available customization documentation. On-site or virtual factory audits can confirm production scale and quality management practices.

What is the typical MOQ and pricing range?

Standard models have an MOQ of 1 set, with prices ranging from $35 for handheld units to $4,200 for high-resolution CIJ systems. Bulk orders (10+ units) often unlock negotiated pricing and extended warranty terms. Handheld and portable models are frequently sold in box quantities when bundled with consumables.

Do suppliers offer customization for bottle coding applications?

Yes, leading suppliers support tailored solutions including print height adjustment (up to 12.7mm), multi-language font libraries, integration with conveyor systems, and specialized inks for non-porous surfaces. Guangzhou Prima and Dongguan Sammi explicitly list food-grade ink, sensor integration, and logo printing as configurable options.

What are the common lead times for batch coding machines?

Standard units ship within 7–15 days after payment confirmation. Customized systems require 20–35 days depending on complexity. Air freight delivers internationally in 5–10 days; sea freight takes 25–40 days but reduces transport costs by 50–60% for container loads.

Are certifications provided for export compliance?

While not explicitly stated in supplier tags, reputable manufacturers typically design CIJ and TIJ systems to meet CE and RoHS standards. Buyers should request certification documentation prior to shipment, especially for regulated industries such as pharmaceuticals and packaged foods. Firmware compliance with local language and date format regulations (e.g., YYYY-MM-DD) is also essential for regional market entry.