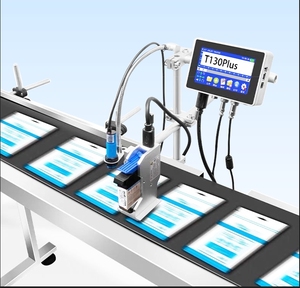

Batch Coding Machine For Pet Bottles

About batch coding machine for pet bottles

Where to Find Batch Coding Machine Suppliers for PET Bottles?

China remains the global epicenter for batch coding machine production, with key manufacturing clusters in Zhejiang, Guangdong, and Henan provinces. These regions host vertically integrated supply chains specializing in industrial marking systems, offering competitive advantages in cost efficiency, technical adaptability, and export readiness. Hangzhou and Guangzhou serve as primary hubs, combining access to precision component suppliers with advanced laser and inkjet subsystem manufacturers within 50km radii.

The concentration of engineering talent and automation specialists enables rapid prototyping and scalable production. Facilities typically integrate R&D labs, CNC machining centers, and assembly lines under one roof, reducing lead times to 20–35 days for standard configurations. Localized sourcing of optical modules, nozzles, and conveyor integration components cuts material costs by 18–25% compared to offshore alternatives. Buyers benefit from mature ecosystems supporting both high-volume orders and customized coding solutions for PET bottle applications across beverage, pharmaceutical, and personal care industries.

How to Choose Batch Coding Machine Suppliers for PET Bottles?

Selecting reliable suppliers requires a structured evaluation based on technical capability, quality assurance, and transactional reliability:

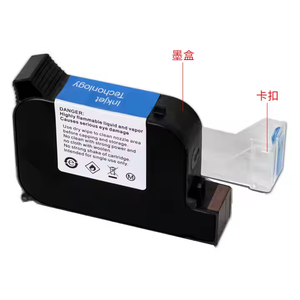

Technology & Application Fit

Identify whether laser or inkjet (CIJ/TIJ) technology aligns with your substrate requirements. UV and fiber lasers are optimal for permanent, high-resolution codes on transparent PET without surface damage. Continuous Inkjet (CIJ) systems offer faster line speeds (up to 120 m/min) and compatibility with curved surfaces. Verify that machines support required print heights (typically 12.7 mm or higher), variable data inputs (date/time/lot/batch), and resistance to environmental factors like moisture and oil.

Quality & Compliance Verification

Confirm adherence to international standards such as CE, RoHS, and ISO 9001. While not all suppliers list certifications explicitly, prioritize those demonstrating compliance through product documentation. Evaluate build quality via available media—look for stainless steel enclosures, IP-rated protection (IP54+), and integration-ready designs (PLC compatibility, encoder inputs).

Production & Customization Capacity

Assess scalability using the following benchmarks:

- Minimum factory area: 2,000m² for dedicated production lines

- In-house engineering teams capable of modifying nozzle positioning, conveyor synchronization, or software interfaces

- Support for OEM branding, language localization, and multi-format code generation

Cross-reference supplier claims with reorder rates (>15%) and on-time delivery performance (target ≥97%) to validate operational consistency.

Procurement Safeguards

Utilize secure payment methods with milestone-based disbursements. Request sample units to evaluate print clarity, startup time, and maintenance intervals before full-scale ordering. Insist on post-delivery technical support, including remote diagnostics and spare parts availability. Analyze response times (≤3 hours is ideal) and after-sales service structure when comparing vendors.

What Are the Best Batch Coding Machine Suppliers for PET Bottles?

| Company Name | Main Technology | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Key Strengths |

|---|---|---|---|---|---|---|---|

| Hangzhou Champ Precision Machinery Co., Ltd. | Laser (UV/Fiber) | $1,800–5,800 | 1 set | 98% | ≤3h | 22% | High-power flying laser coders; 1,189+ laser listings; strong R&D focus |

| Guangzhou Su Ma Information Technology Co., Ltd. | CIJ Inkjet | $64–2,650 | 1 piece/set | 100% | ≤1h | 15% | Consistent on-time fulfillment; specialized CIJ systems for water PET bottles |

| Xinxiang New Bell Information Materials Co., Ltd. | TIJ/Laser | $248–685 | 1 unit | 97% | ≤1h | 19% | Budget-friendly TIJ printers; customization options for packaging labels |

| Guangzhou Dafeng Machinery Co., Ltd. | CIJ/TIJ Inkjet | $200–2,300 | 1 unit | 92% | ≤4h | 18% | Broad customization: font size, color printing, dual print heads, sensor integration |

| Xinxiang Haitop Machinery Equipment Co., Ltd. | Inkjet (Tij/High-Speed) | $259–450 | 1 piece | 100% | ≤3h | 18% | Compact, high-resolution coders; diverse substrate compatibility |

Performance Analysis

Hangzhou Champ leads in laser-based solutions, offering robust industrial systems suitable for high-speed production environments. With over 1,100 laser equipment listings, the company demonstrates deep specialization and innovation capacity. Guangzhou Su Ma stands out for flawless on-time delivery and targeted CIJ solutions for PET water bottling lines. Xinxiang-based suppliers provide cost-effective entry points with flexible configuration options, ideal for SMEs or pilot deployments. Reorder rates between 15–22% indicate moderate customer retention, suggesting room for improvement in long-term support. Prioritize suppliers with sub-3-hour response times and documented technical support frameworks when deploying mission-critical coding infrastructure.

FAQs

What is the typical MOQ for batch coding machines for PET bottles?

Most suppliers offer a minimum order quantity of 1 unit or set, enabling low-risk sampling and small-scale implementation. Bulk pricing applies at 5+ units, with discounts varying by model complexity and technology type.

What are the average lead times?

Standard units ship within 15–25 days after order confirmation. Customized configurations involving conveyor integration or specialized software may require 30–40 days. Air freight adds 5–10 days globally; sea freight ranges from 25–45 days depending on destination port.

Can these machines handle high-speed bottling lines?

Yes. CIJ and flying UV laser models support line speeds exceeding 100 bottles per minute. Ensure the supplier specifies encoder compatibility and real-time date updating to maintain accuracy at peak throughput.

Do suppliers offer customization?

Extensive customization is available, including print content (batch, expiry, QR codes), font dimensions, ink colors (for CIJ), mounting brackets, and control interface integration (Modbus, Ethernet/IP). Some vendors support dual-head setups for simultaneous top-and-side marking.

How to verify machine performance before purchase?

Request video demonstrations showing actual coding on PET samples. Obtain test prints under simulated production conditions. For critical applications, procure physical samples to assess durability, smudge resistance, and readability under barcode scanners.