Manual Batch Coding Machine For Pet Bottles

About manual batch coding machine for pet bottles

Where to Find Manual Batch Coding Machine Suppliers for PET Bottles?

China remains the global epicenter for manufacturing manual batch coding machines tailored for PET bottles, with key industrial hubs concentrated in Zhejiang and Guangdong provinces. These regions host vertically integrated supply chains that specialize in packaging automation equipment, leveraging localized access to precision components, inkjet/thermal transfer systems, and plastic handling technologies. Zhejiang’s Wenzhou and Hangzhou zones are particularly notable for their high concentration of custom coding machine producers, offering scalable production from handheld stamp units to semi-automatic desktop models.

The regional advantage lies in mature ecosystems where design, machining, assembly, and testing occur within compact geographic radii—often under 50km—reducing lead times and logistics overhead. Buyers benefit from rapid prototyping capabilities, flexible MOQs (as low as 1 unit), and cost efficiencies driven by competitive supplier density. Average production cycles range from 7–20 days depending on customization level, while export-ready packaging and multilingual interface options are standard across leading manufacturers.

How to Choose Manual Batch Coding Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation of technical capability, quality assurance, and transactional reliability:

Technical Specifications & Compatibility

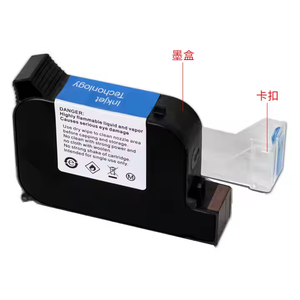

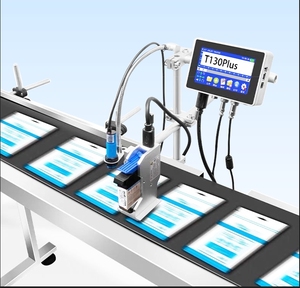

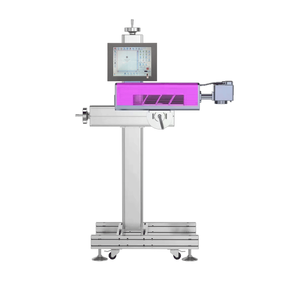

Verify compatibility with PET bottle materials and production line integration needs. Machines should support variable data printing—including batch numbers, expiry dates, barcodes, and logos—using thermal, inkjet, or hot-stamping methods. Confirm adjustable print height (typically 1–10mm), character resolution, and durability of markings under moisture or abrasion conditions.

Quality Management Systems

Prioritize suppliers with documented quality controls, ideally ISO 9001-certified facilities. While not all manufacturers list formal certifications in public data, consistent on-time delivery rates ≥97% and response times ≤5 hours indicate operational discipline. Cross-reference tags such as “Customization options” and “packaging label graphic” to assess design flexibility and client-specific adaptation capacity.

Production Capacity and Scalability

Evaluate supplier infrastructure through available metrics:

- Online revenue exceeding US $360,000 annually suggests established output volume

- Reorder rates above 18% reflect customer retention and product satisfaction

- In-house R&D or engineering teams enable faster customization turnaround

- On-time delivery performance at or above 97% confirms logistical reliability

Suppliers with dedicated customization services—including logo integration, language displays, and material size adjustments—are better positioned to meet niche regulatory or branding requirements.

Transaction Security & Procurement Best Practices

Utilize secure payment mechanisms such as escrow services for initial orders. Request product samples before bulk procurement to validate print clarity, mechanical stability, and ease of operation. Lead times for sample shipments typically range from 5–15 days via express freight. For full orders, confirm FOB or CIF shipping terms and ensure compliance with destination-country electrical safety standards if motorized components are involved.

What Are the Leading Manual Batch Coding Machine Suppliers for PET Bottles?

| Company Name | Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Lianteng Packaging Machinery Co., Ltd. | Custom Manufacturer | US $540,000+ | 97% | ≤4h | 24% | 5 models | $38–$1,600 | Yes (material, size, label, graphic) |

| Zhejiang Lianteng Intelligent Equipment Co., Ltd. | Custom Manufacturer | US $360,000+ | 97% | ≤5h | 18% | 5 models | $30–$539 | Yes (color, size, logo, language) |

| Zhejiang Bespacker Machine Co., Ltd. | Custom Manufacturer | US $530,000+ | 97% | ≤10h | <15% | 4 models | $19–$230 | Yes (DAP, color, material, graphic) |

| Guangzhou Su Ma Information Technology Co., Ltd. | Custom Manufacturer | US $90,000+ | 100% | ≤1h | 16% | 4 models | $40–$2,650 | Limited public detail |

| Jiangsu Sinopak Machinery Co., Ltd. | Custom Manufacturer | US $480,000+ | 100% | ≤4h | <15% | 2 models | $5,800–$6,200 | Mainly integrated into larger lines |

Performance Analysis

Wenzhou Lianteng stands out with the highest reorder rate (24%) and robust customization depth, indicating strong market acceptance and service adaptability. Zhejiang Lianteng offers comparable delivery performance and responsiveness, with clear emphasis on user interface and labeling flexibility. Bespacker provides competitively priced entry-level models, suitable for small-scale operations requiring basic date coding. Guangzhou Su Ma distinguishes itself with a 100% on-time delivery record and sub-1-hour average response time, making it a responsive partner despite lower public customization visibility. Jiangsu Sinopak focuses on high-end automated solutions, positioning its offerings toward integrated production lines rather than standalone manual units.

FAQs

What is the typical MOQ for manual batch coding machines?

Most suppliers offer a minimum order quantity of 1 unit or set, enabling low-risk sampling and pilot testing. Bulk pricing becomes advantageous at 5+ units, with discounts varying by model complexity and customization level.

How long does it take to receive a sample?

Sample processing typically takes 5–15 days, depending on whether standard or customized configurations are requested. International express shipping adds 3–7 days for most destinations.

Can these machines print on curved or irregular PET surfaces?

Yes, many handheld and desktop models are designed with adjustable nozzles or stamp heads to accommodate curved bottle profiles. Confirm print head articulation range and contact pressure settings with the supplier prior to purchase.

Do suppliers offer after-sales technical support?

Leading suppliers provide remote guidance for setup and troubleshooting, often supported by video tutorials or multilingual manuals. Some offer firmware updates or spare part kits upon request.

Are consumables like ink cartridges or ribbons included?

Ink, ribbons, and cleaning solvents are generally sold separately. Buyers should verify compatibility with third-party consumables to avoid vendor lock-in and manage ongoing operating costs effectively.