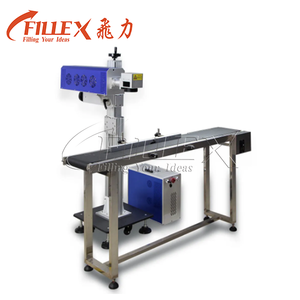

Batch Coding Machine For Water Bottles

1/13

1/13

1/14

1/14

1/18

1/18

1/9

1/9

1/10

1/10

1/28

1/28

About batch coding machine for water bottles

Where to Find Batch Coding Machine Suppliers for Water Bottles?

China remains the global hub for batch coding machine manufacturing, with key industrial clusters in Shandong, Guangdong, and Hubei provinces driving innovation and cost efficiency. Shandong specializes in integrated beverage line solutions, offering automated laser and inkjet systems designed for high-speed PET bottle production. Guangdong’s Dongguan and Shenzhen regions focus on compact, handheld, and digital coding technologies, leveraging advanced electronics supply chains to deliver responsive, customizable machines. Hubei, particularly Wuhan, has emerged as a center for thermal inkjet (TIJ) and portable coding devices, benefiting from regional R&D investment in micro-printing mechanics.

These clusters enable vertical integration of components—from laser diodes and print heads to conveyor integration—reducing lead times and enhancing scalability. Suppliers within these zones typically operate within tightly networked ecosystems where raw material sourcing, precision machining, and final assembly occur within localized supply chains. This proximity supports faster prototyping (7–14 days for standard models), 15–25% lower unit costs compared to Western manufacturers, and flexibility for both low-volume trials and bulk procurement. Average production lead times range from 15 to 30 days, depending on customization level and order size.

How to Choose Batch Coding Machine Suppliers for Water Bottles?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Output Capability

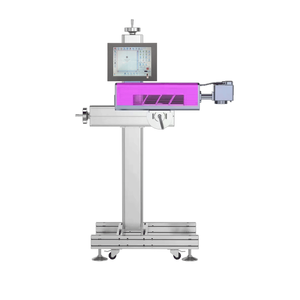

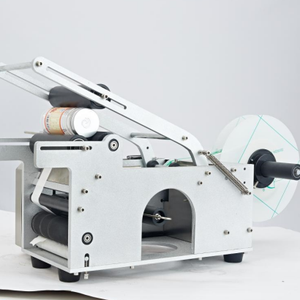

Verify that suppliers offer machines compatible with water bottle materials (PET, HDPE, glass) and production speeds (up to 12,000 bottles/hour). Key technologies include Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), and CO₂/Laser marking systems. Demand documentation for print resolution (minimum 12.7mm height), code permanence (water- and rub-resistant), and compatibility with expiry dates, batch numbers, barcodes, and QR codes. CE or ISO 9001 certification should be confirmed as baseline quality assurance, especially for export to regulated markets.

Production & Customization Capacity

Assess supplier infrastructure using the following benchmarks:

- Minimum factory area of 2,000m² for scalable output

- In-house engineering teams capable of custom nozzle placement, integration with conveyors, or multi-language font support

- Proven experience with food-grade safety standards and non-contact coding processes

Cross-reference online revenue data and reorder rates: suppliers with reorder rates above 25% indicate higher customer satisfaction and product reliability.

Quality Control & Transaction Security

Prioritize suppliers with documented QC protocols, including pre-shipment testing of print accuracy, drying time, and alignment consistency. On-time delivery rates exceeding 90% are indicative of stable production planning. Utilize secure payment mechanisms such as escrow services and request sample units before full orders. Evaluate response time (ideally ≤2 hours) as a proxy for post-sale support responsiveness.

What Are the Best Batch Coding Machine Suppliers for Water Bottles?

| Company Name | Location | Main Technologies | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang V Pack Machinery Co., Ltd. | Jiangsu, CN | CO₂ Laser, UV Printing | $1,800–5,000 | 1 set | 100% | ≤4h | US $970,000+ | 50% |

| Qingzhou Lude Automation Equipment Co., Ltd. | Shandong, CN | Laser, CIJ, Labeling | $3,700–5,700 | 1 set/m³ | 100% | ≤1h | US $1,000+ | <15% |

| Dongguan Sammi Packing Machine Co., Ltd. | Guangdong, CN | Laser, Handheld Inkjet | $550–1,300 | 1 set | 88% | ≤2h | US $380,000+ | <15% |

| Shenzhen Yungchia Robot Technology Co., Ltd. | Guangdong, CN | CIJ, Portable Inkjet | $207–2,530 | 1 piece | 87% | ≤9h | US $40,000+ | 27% |

| Wuhan Phezer Technology Co., Ltd. | Hubei, CN | TIJ, Mini Inkjet | $120–900 | 1 set | 100% | ≤3h | US $150,000+ | <15% |

Performance Analysis

Zhangjiagang V Pack stands out with a 50% reorder rate and broad technology portfolio, indicating strong market confidence in its CO₂ laser and UV coding systems for beverage lines. Qingzhou Lude offers premium automation integration but shows low repeat purchase behavior, suggesting niche or one-off installations. Dongguan Sammi and Wuhan Phezer provide entry-level and portable solutions at competitive prices, ideal for small to mid-sized bottlers seeking flexibility. Shenzhen Yungchia, while offering the lowest price point ($207), has slower response times but a relatively high reorder rate, reflecting functional reliability for budget-conscious buyers. Suppliers with 100% on-time delivery records—Qingzhou Lude, Zhangjiagang V Pack, and Wuhan Phezer—demonstrate robust logistics management suitable for time-sensitive deployments.

FAQs

How to verify batch coding machine supplier reliability?

Cross-check certifications (ISO, CE) through official registries. Request test reports on print adhesion, ink drying time, and resistance to moisture. Analyze verifiable transaction metrics such as on-time delivery rate, response time, and reorder frequency. Conduct virtual audits to assess production floor organization and QC checkpoints.

What is the average sampling timeline for coding machines?

Standard sample production takes 7–14 days. Custom configurations involving unique mounting brackets, software interfaces, or multi-line printing extend timelines to 20–25 days. Air freight shipping adds 5–10 days internationally.

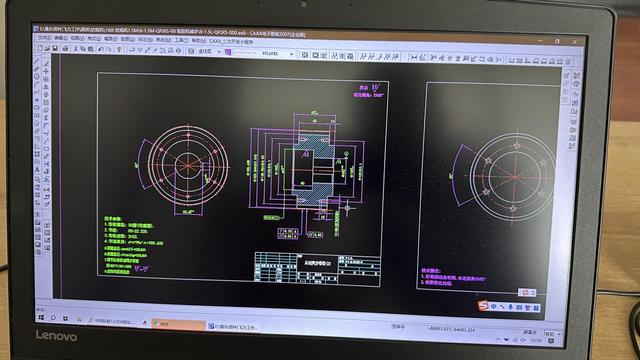

Can suppliers integrate coding machines into existing bottling lines?

Yes, most established suppliers offer integration services for conveyor-mounted CIJ and laser systems. Provide specifications on line speed, bottle diameter, and clearance height to ensure compatibility. Custom PLC interfacing may require additional engineering fees.

Do suppliers offer free samples of coding machines?

Free samples are uncommon due to equipment complexity. However, some suppliers waive fees for demonstration units if followed by a minimum order (typically 3–5 units). Sample costs usually cover 30–50% of unit price and are refundable upon bulk purchase.

What customization options are available for water bottle coding?

Suppliers support variable data printing (expiry dates, batch IDs), multiple languages, barcode formats (Code 128, QR), and ink colors (black, white, blue). Customizations also include handheld vs. fixed-mount designs, wireless control, and corrosion-resistant nozzles for humid environments. Confirm software compatibility for remote job management and logging.