Cnc Lathe 4 Axis Producer

1/3

1/3

0

0

1/3

1/3

CN

CN

1/14

1/14

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/8

1/8

1/3

1/3

1/3

1/3

1/5

1/5

CN

CN

1/5

1/5

1/3

1/3

0

0

1/22

1/22

1/3

1/3

About cnc lathe 4 axis producer

Where to Find CNC Lathe 4 Axis Producers?

China remains the global epicenter for CNC lathe manufacturing, with specialized industrial hubs in Shandong and Guangdong provinces leading production of 4-axis models. Shandong, particularly Jinan, hosts a dense cluster of machinery manufacturers specializing in woodworking and metal-cutting CNC systems. These producers benefit from proximity to raw material suppliers and port infrastructure, enabling efficient export logistics. Guangdong’s Foshan and Zhongshan regions focus on high-precision metal lathes, supported by mature automation supply chains that reduce component lead times by 20–25% compared to non-specialized regions.

The concentration of vertically integrated facilities—spanning casting, machining, assembly, and testing—allows for rapid prototyping and scalable production. Suppliers typically maintain in-house design teams and CNC machining centers, supporting both standard configurations and engineered-to-order machines. Buyers can expect average lead times of 30–45 days for standard 4-axis lathes, with cost advantages of 25–35% over equivalent European or North American-built equipment due to lower labor and operational overheads.

How to Choose CNC Lathe 4 Axis Producers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer true 4-axis functionality (X, Y, Z, and rotational C-axis) with simultaneous control. Evaluate spindle specifications (RPM range, power output), tool turret capacity, and control system compatibility (e.g., Syntec, Siemens, or Fanuc). For metal lathes, verify bed construction (slant-bed vs. flat-bed) and linear guide brand (HIWIN, THK). Woodworking models should include ATC (Automatic Tool Changer) options and dust extraction integration.

Production Infrastructure Assessment

Prioritize manufacturers demonstrating vertical integration and dedicated R&D capacity. Key indicators include:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house machining capabilities for critical components (spindles, turrets, gantries)

- Demonstrated customization experience (e.g., axis configuration, feed systems, automation interfaces)

Cross-reference response time data (<2 hours preferred) and on-time delivery performance (target ≥98%) as proxies for operational efficiency.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE) are not universally listed, consistent on-time delivery (100% among top suppliers in this dataset) indicates process discipline. Use third-party inspection services pre-shipment to validate machine calibration, safety guards, and electrical compliance. Leverage secure payment mechanisms where available, and request test run videos or factory audits before finalizing orders.

What Are the Best CNC Lathe 4 Axis Producers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Jinan Lingrui Cnc Machinery Co., Ltd. | Shandong, CN | Wood Lathe, CNC Milling, Laser Marking | $4,450–$13,600 | 1 piece/set | 100.0% | ≤2h | - | - |

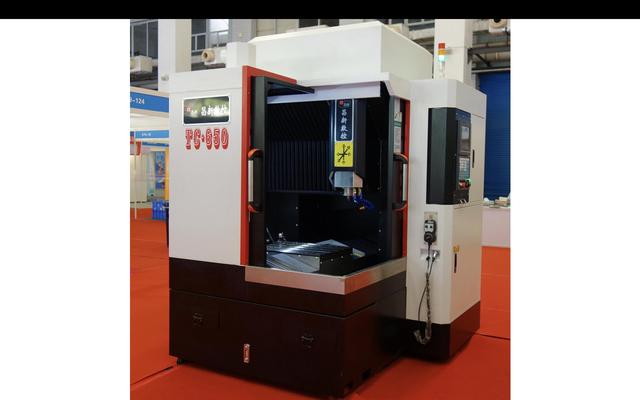

| Zhongshan Tengyue Cnc Technology Co., Ltd. | Guangdong, CN | CNC Lathe | $21,300–$30,000 | 1 unit | 100.0% | ≤2h | - | - |

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, EDM | $7,600–$18,000 | 1 set | 100.0% | ≤1h | 25% | US $690,000+ |

| Foshan Shunde Xinlongke Automation Technology Co., Ltd. | Guangdong, CN | Custom CNC Machines | $10,300–$20,500 | 1 set | 100.0% | ≤3h | <15% | US $30,000+ |

| Jinan Wisdom CNC Equipment Co., Ltd. | Shandong, CN | Wood Lathe, CNC Plasma Cutters | $3,500–$6,666 | 1 set | 100.0% | ≤2h | 33% | US $80,000+ |

Performance Analysis

Suppliers like Zhongshan Tengyue focus on high-end metal lathes with price points above $20,000, indicating investment in precision engineering and robust bed designs. In contrast, Jinan Wisdom CNC and Jinan Lingrui target the mid-tier woodworking market with competitive pricing starting under $4,000, emphasizing multifunctionality and ease of integration. Jinan Hongda stands out with a verified reorder rate of 25% and strong online revenue, suggesting consistent customer satisfaction and export activity. Foshan Shunde Xinlongke offers customization depth—including spindle size, feeder type, and control system branding—making it suitable for buyers requiring tailored configurations. All top-tier suppliers achieve 100% on-time delivery, reinforcing reliability in fulfillment despite varying scale.

FAQs

What is the typical MOQ for 4-axis CNC lathes?

Most suppliers list a minimum order quantity of 1 unit or set, accommodating both trial purchases and bulk procurement. No volume discounts are explicitly stated, but negotiation potential exists for orders exceeding five units.

How long does production and shipping take?

Manufacturing lead time averages 30–45 days after deposit confirmation. Sea freight to major global ports (e.g., Rotterdam, Los Angeles, Sydney) adds 25–40 days depending on origin and destination. Air freight is generally not viable for full machines due to size and weight.

Can I customize the CNC lathe configuration?

Yes, multiple suppliers offer customization options including axis travel, spindle speed, tool magazine type, control system, and structural reinforcements. Foshan-based producers explicitly list parameters such as ball screw type, hydraulic chuck size, and linear guide color as modifiable features.

Do these suppliers provide technical support and training?

While not detailed in public profiles, established exporters typically include basic operation manuals, wiring diagrams, and remote troubleshooting. Advanced support (on-site installation, operator training) may be available at additional cost—confirm availability prior to purchase.

Are 4-axis CNC lathes CE certified?

Certification status is not uniformly disclosed. Buyers targeting EU or North American markets must explicitly request CE/UL documentation and verify compliance with local safety standards (e.g., EN 60204-1 for electrical systems) before import.