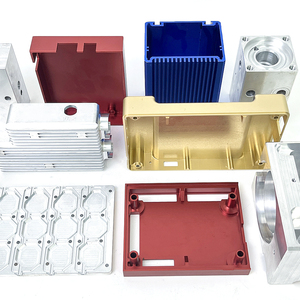

Cnc Machining Rapid Prototyping

About cnc machining rapid prototyping

Where to Find CNC Machining Rapid Prototyping Suppliers?

China remains the global hub for precision CNC machining and rapid prototyping services, with concentrated manufacturing clusters in Zhejiang, Guangdong, and Jiangsu provinces. Hangzhou and Huzhou in Zhejiang Province host a high density of multispecialty suppliers offering integrated digital manufacturing solutions, supported by regional infrastructure for fast logistics and component sourcing. Dongguan in Guangdong specializes in high-precision medical and industrial prototypes, leveraging proximity to Tier-1 electronics manufacturers and advanced material supply chains.

These industrial zones feature vertically integrated workshops equipped with 3-, 4-, and 5-axis CNC systems, enabling complex geometries and tight tolerances (±0.005mm). The ecosystem supports rapid iteration through co-located capabilities in 3D scanning, SLA/DLP resin printing, polyjet modeling, and post-processing techniques such as sandblasting, anodizing, electroplating, and mirror polishing. Buyers benefit from localized tooling and engineering support, reducing prototyping lead times to 7–12 days on average and lowering unit costs by 20–35% compared to Western-based providers.

How to Choose CNC Machining Rapid Prototyping Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Compliance

Verify that suppliers maintain ISO 9001-certified quality management systems—critical for consistent output in low-volume or functional prototyping runs. For international buyers, confirm compliance with material-specific standards such as RoHS for electronics or biocompatibility requirements for medical prototypes. Demand dimensional inspection reports (CMM or laser scanning) and validate process control for materials including aluminum, stainless steel, titanium, brass, engineering plastics (PEBA, TPU, PEEK), and specialty alloys like cobalt-chromium.

Production Infrastructure Audit

Assess key operational metrics:

- Minimum 3-axis CNC milling and turning capacity, with 5-axis capability preferred for complex parts

- In-house design and reverse engineering support, including 3D file creation, DFM analysis, and STL/OBJ/CAD compatibility

- On-site surface treatment and finishing options (e.g., anodizing, powder coating, spray painting, Pantone color matching)

Cross-reference declared response times and on-time delivery rates with actual performance data. Prioritize suppliers reporting ≤6-hour response times and ≥94% on-time delivery to ensure project continuity.

Customization and Transaction Security

Confirm flexibility in customization scope—including logo engraving, material substitution, packaging labeling, and hybrid manufacturing (e.g., combining CNC with 3D printing). Use secure payment mechanisms tied to milestone verification, especially for first-time engagements. Request physical or digital samples prior to full production, particularly when dimensional accuracy, finish quality, or material properties are mission-critical.

What Are the Best CNC Machining Rapid Prototyping Suppliers?

| Company Name | Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Aoyi Trade Co., Ltd. | Multispecialty Supplier | US $180,000+ | 96% | ≤3h | 57% | 2 pieces | $0.90 | Extensive: material, finish, logo, size, coating, 3D scanning, DLP, SLS, electroplating |

| SkyReach Intelligent MFG Limited | Custom Manufacturer | US $20,000+ | 76% | ≤3h | 15% | 1 piece | $0.50–3.89 | Material, color, size, logo, packaging, graphic |

| Huzhou Dear Industry Co., Ltd. | Multispecialty Supplier | US $370,000+ | 100% | ≤6h | 48% | 1–2 pieces | $0.10–2.00 | Material, color, size, hardness, TPU/EPDM options, injection molding integration |

| Yokan Precision Technology (Dongguan) Co., Ltd. | Custom Manufacturer | - | 100% | ≤16h | - | 1 piece / 1 pair | $0.50–60 | Material, size, logo, packaging, graphic; specialized in medical-grade prototypes |

| 24K Investment (Qingdao) Co., Ltd. | Custom Manufacturer | US $10,000+ | 94% | ≤2h | 20% | 1 piece / 100 cm | $0.01–60 | Integrated fabrication: sheet metal, casting, molding, multi-process coordination |

Performance Analysis

Huzhou Dear Industry stands out with a 100% on-time delivery rate and the lowest price floor ($0.10/unit), indicating strong process efficiency and scalability despite longer response windows. Hangzhou Aoyi offers the broadest range of secondary processes and finishes, making it ideal for clients requiring high-fidelity prototypes with near-production surface quality. SkyReach and 24K Investment provide single-piece ordering flexibility and competitive pricing, suitable for iterative design validation. Yokan Precision excels in niche applications such as medical device prototyping but has limited reorder transparency. Suppliers with sub-3-hour response times (Hangzhou Aoyi, SkyReach, 24K Investment) demonstrate superior customer engagement, critical for time-sensitive development cycles.

FAQs

What is the typical lead time for CNC rapid prototyping?

Standard lead times range from 7 to 12 days, including machining, finishing, and quality inspection. Expedited services can reduce this to 3–5 days for simple geometries, depending on material availability and order complexity.

Do suppliers support low-volume production?

Yes, most suppliers listed accommodate low-volume runs (1–100 units) with no significant cost premium. This enables seamless transition from prototype to pilot production without retooling delays.

Can I request custom materials or finishes?

All listed suppliers offer material and finish customization. Common options include anodized aluminum, passivated stainless steel, black oxide, chrome plating, and Pantone-matched paint. Advanced treatments like dark chrome coating, wax infusion, and full-color gypsum printing are available upon request.

Are CAD/STL files required for quoting?

Yes, accurate quotations require 3D models in STEP, IGES, STL, or native CAD formats. Suppliers typically provide DFM feedback within 24 hours to optimize manufacturability and reduce costs.

How are quality inspections conducted?

Reputable suppliers perform first-article inspections using calipers, CMMs, or optical comparators. Inspection reports, including dimensionally critical features, are often shared digitally. Third-party QC audits can be arranged pre-shipment for high-value or regulated components.