Cnc Precision Machining

Top sponsor listing

Top sponsor listing

CN

CN

1/30

1/30

CN

CN

1/18

1/18

1/24

1/24

About cnc precision machining

Where to Find CNC Precision Machining Suppliers?

China remains the global epicenter for CNC precision machining services, with key manufacturing clusters in Guangdong and Jiangsu provinces driving innovation and scale. Dongguan and Huizhou in Guangdong host a dense network of custom manufacturers specializing in high-accuracy metal and plastic components, supported by mature supply chains for raw materials and secondary processing. These regions benefit from proximity to Shenzhen’s electronics hub, enabling rapid prototyping and just-in-time delivery for OEMs in consumer electronics, medical devices, and industrial automation.

The concentration of technical expertise and vertically integrated workshops allows suppliers to offer end-to-end solutions—from design and material sourcing to CNC milling, turning, 5-axis machining, and surface finishing. Buyers gain access to agile production ecosystems capable of fulfilling low-volume prototypes and high-volume runs with lead times averaging 15–25 days. Localized logistics reduce transportation costs by up to 20%, while digital quoting systems enable same-day responses and real-time order tracking.

How to Choose CNC Precision Machining Suppliers?

Effective supplier selection requires rigorous evaluation across three core areas:

Technical Capability Verification

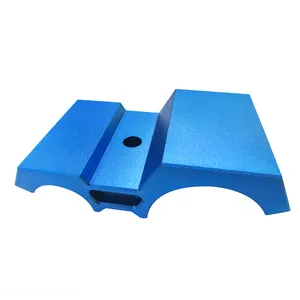

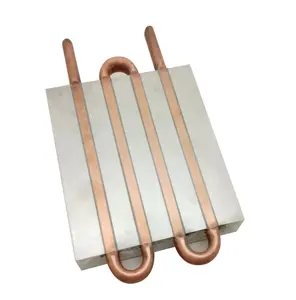

Confirm the supplier's equipment portfolio includes multi-axis CNC centers (3-axis, 4-axis, and 5-axis), Swiss-type lathes, and wire EDM for complex geometries. Materials commonly processed include aluminum (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and engineering plastics (PEEK, Delrin). Request evidence of process control documentation, such as GD&T drawings, first-article inspection reports (FAIR), and CMM measurement records. ISO 9001 certification is a baseline indicator of quality management maturity.

Production Capacity & Scalability Audit

Assess infrastructure through verifiable metrics:

- Minimum factory area exceeding 2,000m² for stable batch processing

- In-house capabilities covering CNC turning, milling, grinding, tapping, and deburring

- Secondary operations like anodizing, plating, powder coating, or laser engraving

Cross-reference on-time delivery performance (target ≥95%) and reorder rates to gauge operational reliability and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers with documented quality assurance protocols, including incoming material inspection, in-process checks, and final product validation. Request sample parts to verify dimensional accuracy, surface finish, and material compliance before scaling. For regulated industries, confirm adherence to RoHS, REACH, or medical-grade standards where applicable.

What Are the Best CNC Precision Machining Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Dongguan Huawang Hardware Products Co., Ltd. | Guangdong, CN | Machining Services, Heat Sinks, Switches, Audio Accessories, Enclosures | US $50,000+ | 100% | ≤2h | 33% | Color, material, size, logo, packaging, label, graphic | 1 unit |

| Dongguan Ouli Electronics & Technology Co., Ltd. | Guangdong, CN | Machining Services, Nuts, Washers, Screws | US $150,000+ | 100% | ≤2h | 45% | N/A | 1 unit |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Vietnam | Machining Services, Sheet Metal Fabrication, Casting, Moulds | US $10,000+ | 100% | ≤2h | - | N/A | 1 piece |

| Huizhou Changsheng Technology Co., Ltd. | Guangdong, CN | Stainless Steel Machining, Wood CNC, Turning/Milling | US $700+ | 100% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic | 5–100 pieces |

| SkyReach Intelligent MFG Limited | Guangdong, CN | CNC Milling/Turning, Rapid Prototyping, Stainless Parts | US $30,000+ | 87% | ≤3h | 15% | Color, material, size, logo, packaging, label, graphic | 1 piece |

Performance Analysis

Dongguan Ouli Electronics leads in customer retention with a 45% reorder rate and strong revenue volume, indicating consistent quality and service execution. Dongguan Huawang and JINKE Vietnam maintain perfect on-time delivery records and support full customization, making them suitable for complex, low-MOQ projects. SkyReach offers broad prototyping capabilities but shows lower delivery reliability (87%), suggesting potential bottlenecks in scaling. All top-performing suppliers respond within 2 hours, underscoring their operational responsiveness. Buyers should prioritize partners with verified in-house machining lines and clear documentation trails for mission-critical applications.

FAQs

How to verify CNC machining supplier reliability?

Validate certifications (ISO 9001, IATF 16949 if automotive-related) and request facility audit reports or video tours. Analyze transaction history indicators such as on-time delivery rate, response speed, and reorder frequency. Review sample workmanship for edge quality, burr control, and tolerance adherence per ANSI Y14.5 or ISO 2768 standards.

What is the typical MOQ and lead time?

Most suppliers accept MOQs as low as 1 piece for prototypes. Series production typically starts at 100–500 units. Standard lead times range from 10–20 days for small batches, extending to 30 days for large or highly complex orders requiring secondary processes.

Do suppliers support custom materials and finishes?

Yes, leading providers accommodate material substitutions (e.g., aluminum to titanium) and surface treatments including hard anodizing, passivation, nickel plating, and black oxide. Custom labeling, laser etching, and packaging configurations are widely available upon request.

Can CNC machining suppliers handle international shipping?

Yes, experienced exporters manage global logistics via air freight (for samples) and sea freight (for bulk shipments). Confirm Incoterms (FOB, CIF, DDP), export packaging standards, and destination-specific customs documentation requirements during procurement planning.

Is sampling available before mass production?

Sampling is standard practice. Most suppliers provide functional prototypes within 5–10 days. Sample costs are often credited toward future orders or waived for contracts exceeding predefined volumes. Always inspect samples for dimensional accuracy, fit, and finish prior to approval.