Crushed Ice Cube Maker

CN

CN

About crushed ice cube maker

Where to Find Crushed Ice Cube Maker Suppliers?

China remains the central hub for crushed ice cube maker manufacturing, with key production clusters in Zhejiang, Guangdong, and Yongkang—renowned for small appliance and commercial kitchen equipment specialization. These regions host vertically integrated supply chains encompassing motor fabrication, stainless steel stamping, and plastic injection molding, enabling rapid prototyping and cost-efficient mass production. The concentration of component suppliers within 50km radii reduces logistics overhead and supports lean manufacturing practices.

Zhejiang’s Ningbo and Yongkang zones focus on compact electric ice crushers and countertop models, leveraging localized access to high-torque DC motors and food-grade polymers. Meanwhile, Guangdong-based manufacturers specialize in large-capacity commercial units, integrating advanced refrigeration modules and automated dispensing systems. This regional diversification allows buyers to source from facilities optimized for either consumer-grade portability or industrial throughput, with typical lead times ranging from 25–40 days for standard orders and up to 60 days for customized configurations.

How to Choose Crushed Ice Cube Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Safety Standards

Verify adherence to internationally recognized certifications such as CE, RoHS, and ETL, particularly for electrical safety and material toxicity. For commercial-grade units, confirm compliance with NSF/ANSI Standard 12—specifically designed for food equipment sanitation. Request test reports for motor insulation class, blade hardness (HRC ≥50), and thermal overload protection mechanisms.

Production Capacity Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum monthly output capacity exceeding 5,000 units for sustained order fulfillment

- In-house tooling and mold-making capabilities to reduce dependency on external vendors

- Blade assembly lines utilizing hardened stainless steel (SUS420 or equivalent) with precision balancing

- Functional testing protocols including continuous operation cycles (≥8 hours) under load conditions

Cross-reference self-reported data with verified metrics such as online revenue and reorder rates to assess scalability and market validation.

Transaction Risk Mitigation

Prioritize suppliers offering third-party payment protection and documented quality assurance processes. Analyze response time (<9h preferred) and on-time delivery performance (target ≥95%) as proxies for operational reliability. Conduct pre-shipment inspections via third-party auditors to verify build consistency against sample units. For high-volume contracts, request factory audit videos highlighting production line automation and QC checkpoints.

What Are the Best Crushed Ice Cube Maker Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Yongkang Tiange Electric Co., Ltd. | Ice Crushers, Juicers, Meat Grinders | 100% | 21% | ≤6h | $70,000+ | $16.09–59.00 | 1–2 pcs |

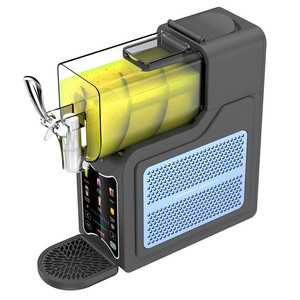

| Ningbo Younger Crops International Trade Co., Ltd. | Slush Machines, Frozen Drink Makers | 75% | 20% | ≤9h | $60,000+ | $73–100 | 500 pcs |

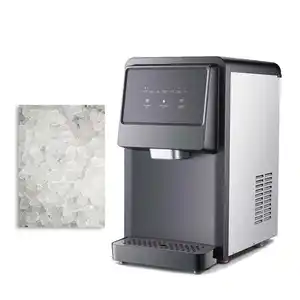

| Hnrb Foods Co., Ltd. | Commercial Ice Makers, Ice Cream Machines | 100% | 22% | ≤1h | $20,000+ | $100–450 | 1 set |

| Wellcooling Intelligent Technology (JM) Co., Ltd. | Commercial Ice Machines, Vending Systems | 100% | 16% | ≤9h | $140,000+ | $388–1,488 | 1 pc/unit |

| Guangzhou Koller Refrigeration Equipment Co., Ltd. | Industrial Ice Makers, Cold Rooms | 100% | <15% | ≤6h | Not disclosed | $1,020–18,000 | 1–2 sets |

Performance Analysis

Yongkang Tiange and Hnrb Foods demonstrate strong operational discipline with 100% on-time delivery and competitive pricing for entry-level and mid-range units. Hnrb stands out with a sub-1-hour average response time, indicating robust customer service infrastructure. Wellcooling leads in revenue volume ($140,000+), reflecting established export channels for premium nugget and granular ice machines targeting hospitality sectors. Guangzhou Koller caters to industrial clients with high-output systems, though its lower reorder rate suggests limited aftermarket engagement. Ningbo Younger offers customization in color, logo, and packaging but imposes high MOQs (500 units), making it suitable for branded retail distribution rather than niche procurement.

FAQs

What materials are commonly used in crushed ice cube makers?

Key components include SUS304 or SUS420 stainless steel for blades and crushing chambers, ABS or food-grade PP for housing, and copper-wound motors for consistent torque. Seals and gaskets should comply with FDA 21 CFR standards for indirect food contact.

What is the typical minimum order quantity (MOQ)?

MOQ varies by supplier tier: consumer-focused manufacturers like Yongkang Tiange offer 1-piece orders, while commercial producers require 1–2 sets. High-end industrial suppliers maintain MOQs at 1 unit, but customized systems may require batch commitments.

Can suppliers provide OEM/ODM services?

Yes, many suppliers support OEM branding, custom color finishes, and logo integration. Ningbo Younger explicitly lists graphic and packaging customization, while others offer label printing and voltage adjustments (110V/220V) for international markets.

What are common power specifications?

Domestic models typically operate at 220–240V/50Hz or 110–120V/60Hz with motor ratings between 150W–300W. Commercial units may require 380V three-phase power for continuous operation in high-demand environments.

How to evaluate ice production efficiency?

Assess output per cycle (e.g., 1–3 kg in 5–10 minutes), noise levels (≤75 dB), and energy consumption (kWh/kg). For continuous use, prioritize units with automatic shut-off, overheating protection, and dual-blade configurations for finer texture consistency.