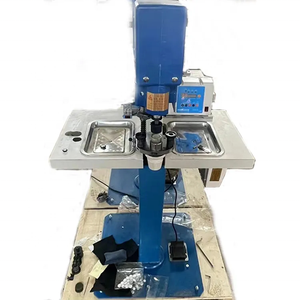

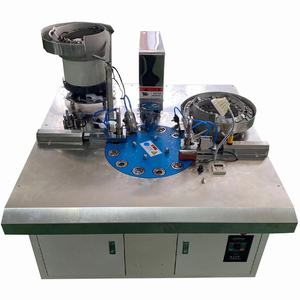

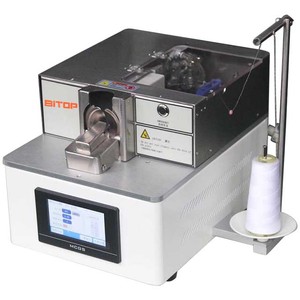

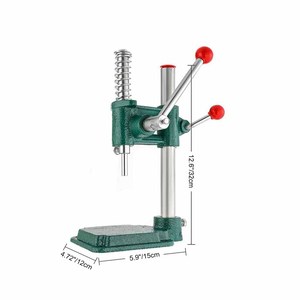

Fabric Button Making Tool

About fabric button making tool

Where to Find Fabric Button Making Tool Suppliers?

China remains the central hub for fabric button making tool manufacturing, with key production clusters in Guangdong, Zhejiang, and Shandong provinces. These regions host vertically integrated facilities specializing in garment accessory machinery, offering scalable production and competitive cost structures. Shenzhen and Hangzhou serve as primary innovation centers, combining precision engineering with rapid prototyping capabilities for both manual and automated equipment.

The industrial ecosystem supports a wide range of processing techniques—including CNC machining, hydraulic pressing, and servo-driven automation—enabling manufacturers to produce tools for handcrafted fabric buttons to high-speed industrial machines. Proximity to textile hubs reduces material lead times, while established export logistics networks ensure efficient global distribution. Buyers benefit from MOQs as low as 1 set for manual models and access to semi-automatic or fully automatic lines suitable for mass production in apparel and upholstery sectors.

How to Choose Fabric Button Making Tool Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

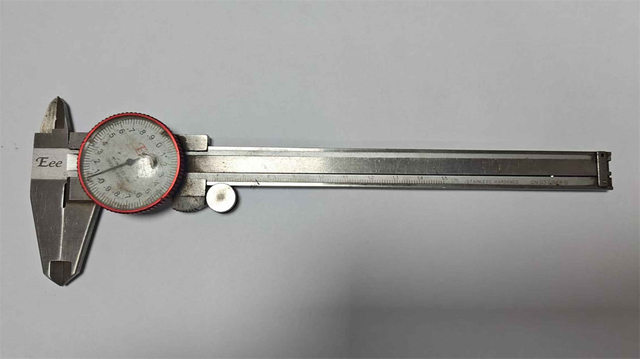

Assess whether suppliers offer appropriate machine types based on production needs: manual press tools for small-scale craft use, semi-automatic models for mid-volume output, or fully automatic systems for industrial applications. Confirm compatibility with target materials (e.g., cotton, wool, synthetic fabrics) and button diameters (typically ranging from 10mm to 38mm). For automated units, verify integration readiness with feeding mechanisms and control systems.

Production Infrastructure Assessment

Prioritize suppliers demonstrating measurable capacity through:

- Minimum factory area supporting dedicated assembly lines

- In-house machining capabilities (CNC, stamping, welding)

- Demonstrated R&D activity reflected in product diversification

Cross-reference online revenue data and reorder rates as indicators of market acceptance and reliability. On-time delivery performance above 97% is recommended for time-sensitive procurement.

Quality and Transaction Assurance

While formal certifications (ISO, CE) are not universally listed, evaluate quality management through response time consistency (≤4 hours preferred), customer reorder rates (>25% indicates satisfaction), and customization transparency. Use secure payment frameworks where possible, especially when engaging newer suppliers without long-term track records. Request functional samples to validate build quality and operational efficiency prior to bulk ordering.

What Are the Best Fabric Button Making Tool Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Hde Garment Accessories Co., Ltd. | Guangdong, CN | Buttons (513) | US $40,000+ | 97% | ≤4h | 25% | No data | $0.05–$900 |

| Hangzhou Qike Technology Co., Ltd. | Zhejiang, CN | Sewing Machines (564) | US $410,000+ | 100% | ≤2h | 17% | No data | $185–$1,150 |

| Qingdao QC Machinery Co.,LTD | Shandong, CN | Metal/Plastic/Fabric Buttons (N/A) | US $120,000+ | 100% | ≤3h | <15% | Eyelet size, hole punching | $900–$2,900 |

| Zhengzhou Pasen Machinery Co., Ltd. | Henan, CN | Apparel Machines & Parts | US $250,000+ | 100% | ≤4h | 16% | Color, material, size, logo, packaging | $1,040–$2,900 |

| Qingdao Laozhang Cap Device Co., Ltd. | Shandong, CN | Button Making Machines (38) | US $9,000+ | - | ≤2h | 50% | No data | $1,800–$6,400 |

Performance Analysis

Shenzhen Hde offers entry-level solutions with one of the lowest price points ($0.05/set), catering to craft businesses and startups. Hangzhou Qike stands out for responsiveness (≤2h) and high on-time delivery (100%), backed by substantial online revenue, indicating strong export experience. Qingdao QC and Zhengzhou Pasen provide mid-to-high-end industrial equipment with documented customization capabilities, suitable for specialized fabric or dimensional requirements. Notably, Qingdao Laozhang reports a 50% reorder rate—the highest among peers—suggesting exceptional post-sale satisfaction despite limited public infrastructure metrics. Suppliers in Zhejiang and Shandong demonstrate superior delivery reliability, while Guangdong-based vendors focus on niche, low-volume tooling.

FAQs

What is the typical MOQ for fabric button making tools?

MOQ varies significantly by machine type: manual tools can have MOQs as low as 1 set, while automated systems often require full carton or set orders (1–2 sets minimum). Some suppliers offer sample pricing at reduced quantities for testing purposes.

How long does production and shipping take?

Lead times typically range from 15 to 30 days for standard models after order confirmation. Customized machines may require an additional 10–15 days for configuration and testing. Air freight delivers samples within 7–10 days; sea freight takes 25–40 days depending on destination.

Can suppliers customize fabric button making machines?

Yes, several suppliers offer customization for material compatibility, button diameter, color coding, branding, and packaging. Advanced modifications such as automated feeding systems or PLC controls are available upon request, particularly from manufacturers with dedicated R&D teams.

Are there certification requirements for importing these tools?

While most manual tools do not require mandatory certifications, electrical or automated models should comply with CE, RoHS, or local safety standards depending on the destination market. Buyers are responsible for verifying compliance with national regulations prior to shipment.

Do suppliers provide technical support or after-sales service?

Support levels vary. High-revenue suppliers with proven reorder rates typically offer basic guidance documentation and remote troubleshooting. For complex installations, negotiate on-site training or third-party commissioning services separately. Warranty terms should be clarified before purchase.