Flexible Pcb Prototype

Top sponsor listing

Top sponsor listing

CN

CN

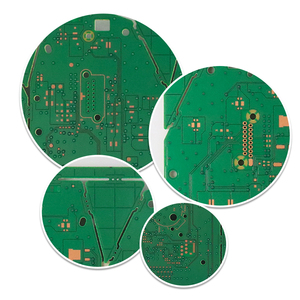

About flexible pcb prototype

Where to Find Flexible PCB Prototype Suppliers?

China remains the global hub for flexible printed circuit board (PCB) manufacturing, with Shenzhen and Suzhou emerging as key centers for prototype production. These regions host vertically integrated supply chains that combine material sourcing, rapid prototyping, and small-to-medium volume assembly under one ecosystem. Shenzhen alone accounts for over 60% of China’s flexible PCB suppliers, supported by a dense network of polyimide film providers, precision etching facilities, and surface mount technology (SMT) lines.

The concentration of technical expertise enables agile development cycles—critical for R&D-driven industries such as wearable electronics, medical devices, and IoT. Localized production reduces lead times to 5–7 days for single-layer prototypes and 8–12 days for multi-layer or rigid-flex designs. Buyers benefit from scalable outputs, with many suppliers capable of transitioning seamlessly from prototype (1–10 pieces) to pilot runs (100+ units) without retooling delays. Cost efficiencies range from 20–40% compared to Western manufacturers due to lower labor costs and streamlined logistics within industrial clusters.

How to Choose Flexible PCB Prototype Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

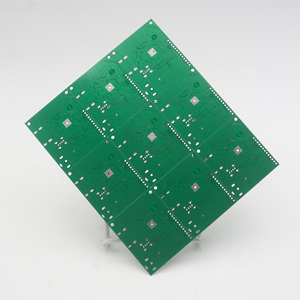

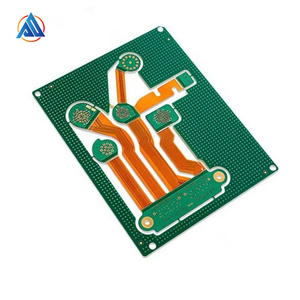

Technical & Material Capabilities

Confirm use of high-temperature polyimide substrates (e.g., Kapton™-grade films) and adherence to IPC-6013 standards for flexible circuits. Verify processing capabilities including laser drilling, controlled-depth routing, and adhesiveless laminate construction for thin (<0.1mm) profiles. Suppliers should support common finishes like ENIG, Immersion Tin, or Carbon Ink based on application requirements.

Quality Assurance Systems

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and RoHS compliance (explicitly stated in product descriptions) serve as proxy indicators of process control. In-circuit testing (ICT), flying probe tests, and AOI inspection should be standard for prototype validation.

Production Flexibility and Responsiveness

Evaluate responsiveness metrics and minimum order quantity (MOQ) structures:

- MOQs as low as 1 piece available for initial prototypes

- Turnaround times averaging 5–10 business days depending on layer count

- Response times under 5 hours indicate strong customer service infrastructure

- Reorder rates above 25% suggest client satisfaction and reliability

Cross-reference supplier claims with verifiable performance tags such as on-time delivery records and online transaction volumes where available.

What Are the Best Flexible PCB Prototype Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Prototype MOQ | Starting Price (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Ac Electronic Technology Co., Ltd. | Shenzhen, CN | Other PCB & PCBA, PCBA | US $140,000+ | 100% | ≤3h | 25% | 1 pc | $0.96 |

| Shenzhen Run Zi Yang Electronics Company Limited | Shenzhen, CN | FPC, Other PCB & PCBA, Wiring Harness | US $7,000+ | 100% | ≤9h | - | 1 pc | $0.10 |

| Shenzhen Seeme Technology Co., Ltd. | Shenzhen, CN | PCBA, Other Electronic Components, Smart GPS Tracker | US $10,000+ | 100% | ≤5h | 25% | 2 pcs | $1.00 |

| Shenzhen Liansheng Electronic Industry Co., Ltd. | Shenzhen, CN | FPC, FFC, Rigid-Flex PCB, Sensor Hardware | - | 100% | ≤3h | - | 1 pc | $0.40 |

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | Customization options: color, size, logo, packaging | US $50,000+ | 92% | ≤3h | 16% | 1 pc | $0.30 |

Performance Analysis

Shenzhen-based suppliers dominate in delivery reliability (100% on-time rate across four out of five companies) and fast response times (≤3h for three suppliers). Shenzhen Ac Electronic Technology leads in verified sales volume (US $140,000+), indicating strong market penetration and repeat business. Suzhou Engine Electronic offers the lowest starting price at $0.30 per unit but has a lower on-time delivery rate (92%) and moderate reorder frequency (16%), suggesting potential scalability constraints. Multiple suppliers offer true low-volume prototyping with MOQs of 1 piece and pricing below $1.00, enabling cost-effective design iteration.

FAQs

How to verify flexible PCB prototype supplier reliability?

Assess on-time delivery history, response time consistency, and reorder rates as practical proxies for reliability. Request sample builds to evaluate dimensional accuracy, solder mask integrity, and electrical continuity. For long-term partnerships, conduct virtual factory audits to confirm cleanroom handling, ESD-safe workstations, and test equipment availability.

What is the typical lead time for flexible PCB prototypes?

Standard lead times range from 5 to 7 days for 1–2 layer designs. Multi-layer or rigid-flex prototypes may require 10–14 days. Express services (3–5 days) are often available at a premium. Shipping via international courier adds 3–7 days depending on destination.

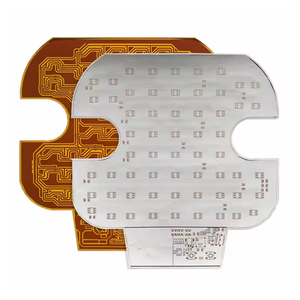

Can suppliers accommodate custom specifications?

Yes, most suppliers support full customization including layer stack-up, coverlay placement, stiffener integration, and impedance control. Design for manufacturability (DFM) feedback is typically provided within 24 hours of file submission. Some offer free Gerber review and layout optimization.

Do flexible PCB suppliers provide RoHS-compliant materials?

RoHS compliance is standard among listed suppliers, with explicit mention of lead-free processing and halogen-free options. Material declarations and compliance certificates can usually be provided upon request, especially for regulated sectors like medical or aerospace.

What file formats are required for ordering prototypes?

Standard submissions include Gerber files (RS-274X), drill files ( Excellon), and a Bill of Materials (BOM) if assembly is requested. IDF or STEP files may be needed for mechanical integration checks. Most suppliers accept common ECAD exports from Altium Designer, KiCad, Eagle, and Cadence Allegro.