Fully Automatic Khakhra Making Machine

CN

CN

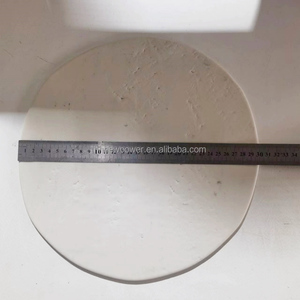

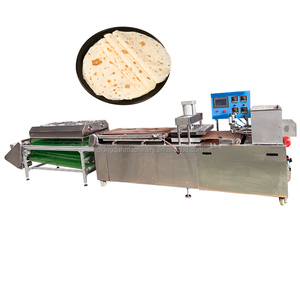

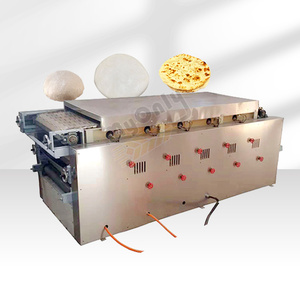

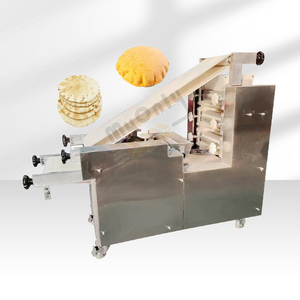

About fully automatic khakhra making machine

Where to Find Fully Automatic Khakhra Making Machine Suppliers?

China remains the dominant hub for industrial food processing equipment manufacturing, with key supplier clusters concentrated in Henan and Shandong provinces. These regions host specialized manufacturers of grain product machinery, leveraging mature supply chains for sheeting rollers, heating systems, and automated conveying components. Henan’s Zhengzhou area serves as a central logistics node, enabling efficient export distribution across Asia, Europe, and North America. Shandong’s industrial base benefits from proximity to steel and electrical component suppliers, reducing material costs by 15–20% compared to non-specialized regions.

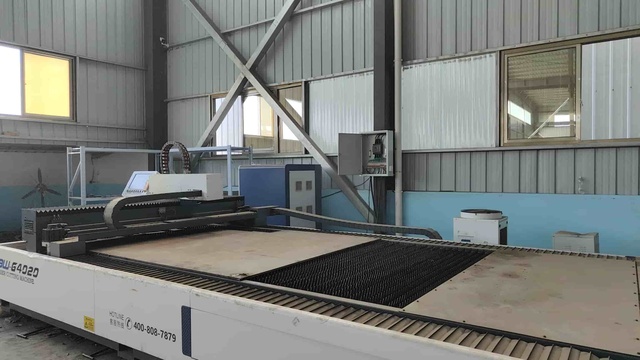

The concentration of technical expertise and vertically integrated production facilities allows for rapid prototyping and scalable output. Manufacturers typically operate end-to-end production lines—from CNC machining and welding to final assembly—within single-site factories. This integration supports lead times averaging 20–35 days for standard configurations, with bulk order capacity reaching 50+ units per month. Buyers gain access to flexible production runs, from small commercial batches to fully automated turnkey lines capable of producing 1,500–3,000 khakhras per hour.

How to Choose Fully Automatic Khakhra Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, quality assurance, and transaction reliability.

Technical Compliance and Certification

Verify adherence to international safety and performance standards. While not universally mandated, ISO 9001 certification indicates formalized quality management systems. For EU and North American markets, CE marking is essential for regulatory compliance. Request documentation on electrical safety (IEC 60204), thermal control accuracy, and material contact compliance (e.g., food-grade stainless steel construction).

Production Capacity Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams supporting customization (e.g., dough thickness adjustment, speed modulation)

- Integrated CNC and welding capabilities to ensure precision in critical components like rolling drums and conveyor belts

- Cross-reference online revenue data and reorder rates as proxies for market acceptance and operational stability

Transaction and Quality Safeguards

Utilize secure payment mechanisms such as third-party escrow services until post-delivery inspection is completed. Prioritize suppliers with documented on-time delivery records (≥95%) and response times under 3 hours. Pre-shipment inspections and sample testing are critical—evaluate machine performance using standardized dough formulations to assess consistency in baking, shaping, and throughput.

What Are the Best Fully Automatic Khakhra Making Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Henan Yanneng Intelligent Technology Co., Ltd. | Henan, CN | Grain Product Making Machines, Snack Machines | $900–2,000 | 1 set | 100% | ≤2h | US $120,000+ | 46% |

| YANN TECHNOLOGY LLC | Shandong, CN | Grain Product Making Machines, Packaging Machines | $900–8,000 | 1 set | Not specified | ≤1h | Not specified | Not specified |

| Zhengzhou Youhoo Machinery Co., Ltd. | Henan, CN | Other Snack Machines, Grain Product Machines | $400–8,500 | 1 set | 100% | ≤2h | US $30,000+ | <15% |

| Zhengzhou Qiongdan Machinery Co., Ltd. | Henan, CN | Grain Product Making Machines, Food Processing Lines | $900–9,000 | 1 set | 100% | ≤3h | US $10,000+ | <15% |

| Jinan Star Bake Machinery Equipment Co., Ltd. | Shandong, CN | Grain Product Making Machines, Dough Sheeters | $2,000–8,500 | 1 set | 100% | ≤7h | US $310,000+ | 33% |

Performance Analysis

Henan-based suppliers demonstrate strong operational discipline, with 100% on-time delivery rates across three verified manufacturers. Henan Yanneng stands out with a 46% reorder rate and responsive communication, indicating customer satisfaction and service reliability. Jinan Star Bake leads in reported online revenue (US $310,000+), reflecting significant market penetration and production scale. While some suppliers offer low entry prices (e.g., $400 for semi-manual models), fully automatic systems typically range from $2,000–$8,500, aligning with automation level, hourly output, and build quality. Buyers seeking high-volume production should prioritize suppliers with comprehensive food processing line experience and documented after-sales support.

FAQs

How to verify supplier reliability for khakhra making machines?

Confirm certifications through issuing bodies and request test reports for electrical and mechanical components. Analyze transaction history, focusing on consistent delivery performance and buyer feedback related to machine durability and technical support. Video audits of production floors can validate claimed capabilities.

What is the typical lead time for these machines?

Standard units ship within 20–30 days after order confirmation. Customized configurations involving specific voltage requirements, output adjustments, or non-standard dimensions may extend lead times to 45 days.

Can suppliers accommodate customization requests?

Yes, most established manufacturers support modifications including adjustable rolling thickness (0.5–3mm), variable speed drives, and integration with upstream mixers or downstream packaging systems. Submit detailed specifications for accurate quoting and feasibility assessment.

Do suppliers provide samples or trial units?

Full-machine samples are rarely offered free of charge due to cost and size. However, many suppliers allow video demonstrations of running units or provide baked product samples produced by the machine. Some may offer rental or demo units upon negotiation.

What are common payment and shipping terms?

Payment terms typically include T/T (30% deposit, 70% before shipment) or platform-based escrow. Shipping is commonly FOB Zhengzhou or Qingdao, with sea freight recommended for cost efficiency on single or multiple-unit orders. Air freight is viable for urgent single-machine deliveries but increases transport costs by 200–300%.