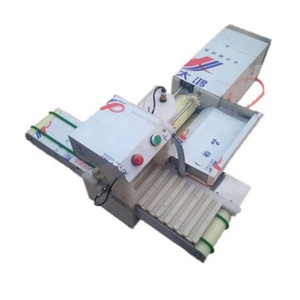

Fully Automatic Khoya Making Machine

About fully automatic khoya making machine

Where to Find Fully Automatic Khoya Making Machine Suppliers?

China remains the dominant hub for fully automatic khoya making machine manufacturing, with key production clusters in Henan, Shandong, and Shanghai. These regions host vertically integrated facilities specializing in food processing equipment, leveraging localized supply chains for stainless steel components, precision molds, and automation systems. Henan and Shandong provinces account for over 70% of China’s grain-based food machinery exporters, supported by mature ecosystems that include R&D centers, CNC fabrication units, and export logistics networks within concentrated industrial zones.

Manufacturers in these clusters benefit from economies of scale, enabling competitive pricing and rapid prototyping. Average factory sizes exceed 5,000m², with many suppliers operating dedicated assembly lines for automated dairy and bakery processing systems. Buyers gain access to flexible production runs—ranging from single-unit trials to bulk orders—supported by standardized component inventories and modular design frameworks. Lead times for standard configurations typically range from 20–35 days, with customization adding 7–14 days depending on technical complexity.

How to Choose Fully Automatic Khoya Making Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across three critical dimensions:

Technical Capability Verification

Confirm that suppliers utilize food-grade stainless steel (typically SUS304 or equivalent) in construction and integrate variable-frequency drives (VFDs) for precise control of belt speed, temperature, and molding pressure. Machines should support adjustable parameters for moisture control, cooling cycles, and yield optimization (reported outputs range from 50–300 kg/hour). Request validation of motor specifications, heating element durability, and mold design compatibility with traditional khoya textures.

Production & Quality Assurance Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum 2,000m² production area with in-house machining capabilities

- Dedicated quality inspection protocols for noise levels, energy consumption, and continuous operation testing (8–12 hour cycles)

- Evidence of compliance with international standards such as ISO 9001, CE, or equivalent food safety certifications

Cross-reference online transaction histories and delivery performance: consistent on-time delivery rates ≥95% indicate operational reliability. Prioritize suppliers with documented after-sales service procedures and multilingual technical support.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure product verification prior to final disbursement. Conduct video audits of factory operations to confirm automation levels and inventory readiness. Sample testing is strongly recommended—assess output consistency, ease of cleaning, and power efficiency under real-world conditions before full-scale ordering.

What Are the Best Fully Automatic Khoya Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options | Main Product Focus |

|---|---|---|---|---|---|---|---|---|

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Henan, CN | US $130,000+ | 100% | ≤2h | <15% | $800–8,800 | Mold size, shape, thickness, capacity, automation level, material finish | Paratha, pita, chapati, and khoya processing systems |

| Shanghai Chengtao Intelligent Equipment Co., Ltd. | Shanghai, CN | US $670,000+ | 100% | ≤3h | 40% | $4,000–34,000 | Color, mold pattern, filling weight, packaging integration, motor specs | Encrusting machines, dumpling makers, siomai systems |

| Shandong Aida Machinery Co., Ltd. | Shandong, CN | US $40,000+ | 100% | ≤2h | <15% | $12,000–16,800 | Limited customization noted; focus on extrusion line configuration | Snack extruders, cake lines, cheetos-style processors |

| Sumec Industrial INC | Not specified | Not available | Not available | ≤1h | Not available | $1,100–1,400 | Multiple configurable models for momo, croquette, and mooncake formats | Grain product machines, meat slicers, vegetable cutters |

| Qixian Xincheng E-Commerce Co., Ltd. | Henan, CN | US $4,000+ | 100% | ≤1h | <15% | $331–1,050 | Basic automation; limited evidence of advanced customization | Roti, prata, baozi, and Xiao Long Bao equipment |

Performance Analysis

Shanghai Chengtao stands out with the highest reorder rate (40%) and broadest price coverage, indicating strong customer retention and adaptability across commercial scales. Jiaozuo Dingchang offers mid-range pricing with extensive customization options, ideal for buyers seeking tailored khoya texture and throughput profiles. Shandong Aida targets high-capacity snack production but shows minimal emphasis on khoya-specific functionality. Sumec and Qixian Xincheng provide entry-level automation at aggressive price points, though transparency on certification and long-term support remains limited. Buyers requiring GMP-compliant or export-certified systems should prioritize suppliers with verifiable quality documentation and engineering teams capable of validating thermal and mechanical performance.

FAQs

How to verify supplier credibility for khoya making machines?

Validate technical claims through facility videos, third-party inspection reports, and sample evaluations. Check consistency between listed product specifications and actual machine builds. Assess responsiveness, documentation clarity, and willingness to provide references from past international clients.

What is the typical minimum order quantity (MOQ)?

Most suppliers list an MOQ of 1 set, facilitating trial purchases and small business adoption. Bulk discounts generally apply at 3+ units, with negotiation leverage increasing at 5+ units.

Are customization options available?

Yes, leading suppliers offer customization in mold geometry, production capacity, automation degree, cooling systems, and user interface languages. Advanced modifications may require CAD submissions or prototype approvals, extending lead time by up to two weeks.

Do suppliers provide installation and training support?

Support varies. Some manufacturers include remote guidance via video or manuals; others offer on-site technician deployment at additional cost. Clarify service terms—including warranty duration (typically 12 months)—before purchase.

Can these machines be exported globally?

All listed suppliers support international shipping. Confirm voltage compatibility (commonly 220V/380V), plug types, and compliance with local food safety regulations. FOB terms are standard, with sea freight recommended for cost efficiency on heavy machinery shipments.